Abstract

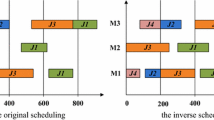

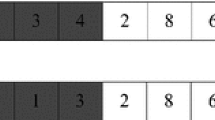

In this paper, a novel inverse scheduling strategy has been proposed to solve dynamic flowshop inverse scheduling problem (DFISP) with random job arrivals and machine breakdowns. Firstly, a mathematical model of DFISP is developed to minimize the adjustment of the parameter. Secondly, an adaptive hybrid algorithm is proposed to solve the DFISP with dynamic events and uncertain processing parameters. The hybrid algorithm is combined improved GA with an adaptive local search (GA-LSAM). A new decimal system encoding method is proposed to ensure parameter controllable, which contains 4-layer information in one chromosome. GA-LSAM applies a separate local search process to improve quality of solutions. Thirdly, a simulator is designed to generate the unexpected disruptions in order to simulate dynamic events. The proposed algorithm can solve 90 public flowshop instances. The comparison with the traditional scheduling and the inverse scheduling shows a good performance of the algorithms with an average deviation of only 2.00%. The analysis of variance has been carried out to determine the significant difference of the algorithms. Finally, inverse scheduling also has been applied to solve a real factory instance with dynamic events. The result shows that GA-LSAM algorithm outperforms other algorithms in terms of searching for quality and efficiency.

Similar content being viewed by others

References

Pan, Q.K., Wang, L., Mao, K., Zhao, J.H., Zhang, M.: An effective artificial bee colony algorithm for a real-world hybrid flowshop problem in steel making proces. IEEE Trans. Autom. Sci. Eng. 10(2), 307–322 (2013)

Solano-Charris, E.L., Montoya-Torres, J.R., Paternina-Arboleda, C.D.: Ant colony optimization algorithm for a Bi-criteria 2-stage hybrid flowshop scheduling problem. J. Intell. Manuf. 22(5), 815–822 (2011)

Kundakcı, N., Kulak, O.: Hybrid genetic algorithms for minimizing makespan in dynamic job shop scheduling problem. Comput. Ind. Eng. 96(C), 31–51 (2016)

Rahmani, D., Ramezanian, R.: A stable reactive approach in dynamic flexible flow shop scheduling with unexpected disruptions: a case study. Comput. Ind. Eng. 98, 360–372 (2016)

Shen, X.N., Yao, X.: Mathematical modeling and multi-objective evolutionary algorithms applied to dynamic flexible job shop scheduling problems. Inf. Sci. 298, 198–224 (2015)

Wang, S., Su, H., Wan, G.: Resource-constrained machine scheduling with machine eligibility restriction and its applications to surgical operations scheduling. J. Comb. Optim. 30(4), 982–995 (2015)

Brucker, P., Shakhlevich, N.V.: Inverse scheduling with maximum lateness objective. J. Sched. 12, 475–488 (2009)

Christos, K.: Inverse scheduling with controllable job parameters. Int. J. Serv. Oper. Manag. 1, 35–43 (2005)

Brucker, P., Shakhlevich, N.V.: Inverse scheduling: two-machine flow-shop problem. J. Sched. 14, 239–256 (2011)

Chen, R.J., Chen, F., Chun, T.G.: Inverse problems of a single machine scheduling to minimize the total completion time. J. Shanghai Second Polytech. Univ. 22(2), 1–7 (2005)

Chen, R.J., Tang, G.C.: Inverse problems of supply chain scheduling and flow shop scheduling. Oper. Res. Manag. Sci. 18(2), 80–84 (2009)

Pham, H., Lu, X.: Inverse problem of total weighted completion time objective with unit processing time on identical parallel machines. J. East China Univ. Sci. Technol. 38(6), 757–761 (2012)

Li, S.S., Brucker, P., Ng, C.T., Cheng, T.C.E., Shakhlevich, N.V., Yuan, J.J.: A note on reverse scheduling with maximum lateness objective. J. Sched. 16, 417–422 (2013)

Nie, L., Gao, L., Li, P., Li, X.: A GEP-based reactive scheduling policies constructing approach for dynamic flexible job shop scheduling problem with job release dates. J. Intell. Manuf. 24(4), 763–774 (2013)

Heydari, M., Aazami, A., Shekarian, M.: Two-objective job shop scheduling problem with sequence-dependent setup times. Appl. Math. Model. (2017)

Jamili, A.: Robust job shop scheduling problem: mathematical models, exact and heuristic algorithms. Expert Syst. Appl. 55, 341–350 (2016)

Vahit, K.: An object-oriented approach for multi-objective flexible job-shop scheduling problem. Expert Syst. Appl. Int. J. 45(C), 71–84 (2016)

Hosseinabadi, A.A.R., Siar, H., Shamshirband, S., Shojafar, M., Nizam, M.H.: Using the gravitational emulation local search algorithm to solve the multi-objective flexible dynamic job shop scheduling problem in small and medium enterprises. Ann. Oper. Res. 229, 1–24 (2014)

Barrett, R.T., Barman, S.A.: SLAMII simulation study of a simplified flowshop. Simulation 47, 181–189 (1986)

Pickardt, C.W., Hildebrandt, T., Branke, J., et al.: Evolutionary generation of dispatching rule sets for complex dynamic scheduling problems. Int. J. Prod. Econ. 145(1), 67–77 (2013)

Wang, D.J., Liu, F., Jin, Y.: A multi-objective evolutionary algorithm guided by directed search for dynamic scheduling. Comput. Oper. Res. (2016)

Riccardo, M., Chee, Y.W., Chandra, S.L.: Mitigating supply and production uncertainties with dynamic scheduling using real-time transport information. Int. J. Prod. Res. 52(17), 5223–5235 (2014)

Petronijević, J., Petrović, M., Vuković, N., Mitić, M., Babić, B., Miljković, Z.: Integrated process planning and scheduling using multi-agent methodology. Appl. Mech. Mater. 834, 193–198 (2016)

Branco, R.M., Coelho, A.S., Mayerle, S.F.: Hybrid genetic algorithms: solutions in realistic dynamic and setup dependent job-shop scheduling problems. Int. J. Prod. Manag. Eng. 4, 75–85 (2016)

Gómez-Gasquet, P., Andrés, C., Lario, F.C.: An agent-based genetic algorithm for hybrid flowshops with sequence dependent setup times to minimise makespan. Expert Syst. Appl. 39(9), 8095–8107 (2012)

Gourgand, M., Grangeon, N., Norre, S.: Metaheuristics and Performance Evaluation Models for the Stochastic Permutation Flow-Shop Scheduling Problem. Flexibility and Robustness in Scheduling. ISTE, Hoboken (2010)

Kumbhare, A.G., Simmhan, Y., Frincu, M., Prasanna, V.K.: Reactive resource provisioning heuristics for dynamic dataflows on cloud infrastructure. IEEE Trans. Cloud Comput. 3(2), 105–118 (2015)

Vinod, V., Sridharan, R.: Simulation modeling and analysis of due-date assignment methods and scheduling decision rules in a dynamic job shop production system. Int. J. Prod. Econ. 129(1), 127–146 (2011)

Taillard, E.: Benchmarks for basic scheduling problems. Eur. J. Oper. Res. 64, 278–285 (1993)

Araghi, M.E.T., Jolai, F., Rabiee, M.: Incorporating learning effect and deterioration for solving a SDST flexible job-shop scheduling problem with a hybrid meta-heuristic approach. Int. J. Comput. Integr. Manuf. 27(8), 733–746 (2014)

Acknowledgements

The authors would like to thank the editor and anonymous referees whose comments helped a lot in improving this paper. This research work was supported by the National Science Foundation of China (NSFC) under Grant No. 51605267; the Natural Science Foundation of Shandong Province, China, under Grant No. ZR2016EEQ07; and Colleges and universities of Shandong province science and technology plan projects under Grant No. J16LB04.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mou, J., Gao, L., Guo, Q. et al. A hybrid heuristic algorithm for flowshop inverse scheduling problem under a dynamic environment. Cluster Comput 20, 439–453 (2017). https://doi.org/10.1007/s10586-017-0734-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10586-017-0734-6