Abstract

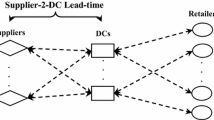

An integrated scheduling problem under a make-to-order supply chain network is addressed. This problem considers integrated production and transportation scheduling with realistic supply chain features such as unrelated parallel shop and product batch-based transportation. The mathematical model for this problem is presented, which is formulated as a bilevel mixed-integer nonlinear program. A novel bilevel evolutionary optimization model based on memetic algorithm is proposed to resolve this problem because the problem is hard-to-tackle for mathematical programming techniques and traditional intelligent techniques. The effectiveness of the proposed optimization model is validated through a series of numerical experiments. The experimental results also confirmed that the proposed optimization model is superior to other three intelligent optimization models.

Similar content being viewed by others

References

Armentano, V., Shiguemoto, A., Lokketangen, A.: Tabu search with path relinking for an integrated production-distribution problem. Comput. Oper. Res. 38(8), 1199–1209 (2011)

Averbakh, I.: On-line integrated production-distribution scheduling problems with capacitated deliveries. Eur. J. Oper. Res. 200(2), 377–384 (2010)

Bard, J., Nananukul, N.: The integrated production-inventory-distribution-routing problem. J. Sched. 12(3), 257–280 (2009)

Ben-Ayed, O., Blair, C.: Computational difficulties of bilevel linear programming. Oper. Res. 38(3), 556–560 (1990)

Beyer, H.-G., Schwefel, H.-P.: Evolution strategies: a comprehensive introduction. J. Nat. Comput. 1(1), 3–52 (2002)

Bilgen, B., Celebi, Y.: Integrated production scheduling and distribution planning in dairy supply chain by hybrid modelling. Ann. Oper. Res. 211(1), 55–82 (2013)

Cakici, E., Mason, S., Kurz, M.: Multi-objective analysis of an integrated supply chain scheduling problem. Int. J. Prod. Res. 50(10), 2624–2638 (2012)

Cattaruzza, D., Absi, N., Feillet, D., Vidal, T.: A memetic algorithm for the multi-trip vehicle routing problem. Eur. J. Oper. Res. 236(3), 833–848 (2014)

Chen, Z.: Integrated production and outbound distribution scheduling: review and extensions. Oper. Res. 58(1), 130–148 (2010)

Chen, Z., Vairaktarakis, G.: Integrated scheduling of production and distribution operations. Manage. Sci. 51(4), 614–628 (2005)

Delavar, M., Hajiaghaei-Keshteli, M., Molla-Alizadeh-Zavardehi, S.: Genetic algorithms for coordinated scheduling of production and air transportation. Expert Syst. Appl. 37(12), 8255–8266 (2010)

Divsalar, A., Vansteenwegen, P., Sorensen, K., Cattrysse, D.: A memetic algorithm for the orienteering problem with hotel selection. Eur. J. Oper. Res. 237(1), 29–49 (2014)

Fu, F.: Integrated scheduling and batch ordering for construction project. Appl. Math. Model. 38(2), 784–797 (2014)

Garcia, J.M., Lozano, S., Canca, D.: Coordinated scheduling of production and delivery from multiple plants. Robot. Comput.-Integr. Manuf. 20(3), 191–198 (2004)

Geem, Z., Kim, J., Loganathan, G.: A new heuristic optimization algorithm: harmony search. Simulation 76(2), 60–68 (2001)

Geismar, H., Laporte, G., Lei, L., Sriskandarajah, C.: The integrated production and transportation scheduling problem for a product with a short lifespan. INFORMS J. Comput. 20(1), 21–33 (2008)

Glover, F.: Tabu search-part 1. ORSA J. Comput. 1(2), 190–206 (1989)

Guo, Z.X., Wong, W.K., Leung, S.Y.S.: A hybrid intelligent model for order allocation planning in make-to-order manufacturing. Appl. Soft Comput. 13(3), 1376–1390 (2013)

Guo, Z., Zhang, D., Liu, H., He, Z., Shi, L.: Green transportation scheduling with pickup time and transport mode selections using a novel multi-objective memetic optimization approach. Transp. Res. Part D (2016). https://doi.org/10.1016/j.trd.2016.02.003

Guo, Z.X., Ngai, E.W.T., Yang, C., Liang, X.: An RFID-based intelligent decision support system architecture for production monitoring and scheduling in a distributed manufacturing environment. Int. J. Prod. Econ. 159, 16–28 (2015)

Holland, J.H.: Erratum: genetic algorithms and the optimal allocation of trials. SIAM J. Comput. 2(2), 88–105 (2006)

Liu, S., Papageorgiou, L.G.: Multiobjective optimisation of production, distribution and capacity planning of global supply chains in the process industry. OMEGA-Int. J. Manag. Sci. 41(2), 369–382 (2013)

Low, C., Li, R., Chang, C.: Integrated scheduling of production and delivery with time windows. Int. J. Prod. Res. 51(3), 897–909 (2013)

Meisel, F., Kirschstein, T., Bierwirth, C.: Integrated production and intermodal transportation planning in large scale production-distribution-networks. Transp. Res. Part E 60(6), 62–78 (2013)

Michalewicz, Z.: Genetic + data structures = evolution programs. Comput. Stat. Data Anal. 24(3), 372–373 (1999)

Moscato, P.: On evolution, search, optimization, genetic algorithms and martial arts: Towards memetic algorithms. Caltech Concurrent Computation Program (report 826) (1989)

Neri, F., Cotta, C.: Memetic algorithms and memetic computing optimization: a literature review. Swarm Evol. Comput. 2(1), 1–14 (2012)

Piewthongngam, K., Pathumnakul, S., Homkhampad, S.: An interactive approach to optimize production-distribution planning for an integrated feed swine company. Int. J. Prod. Econ. 142(2), 290–301 (2013)

Sawik, T.: Monolithic versus hierarchical approach to integrated scheduling in a supply chain. Int. J. Prod. Res. 47(21), 5881–5910 (2009)

Selvarajah, E., Zhang, R.: Supply chain scheduling to minimize holding costs with outsourcing. Ann. Oper. Res. 217(1), 479–490 (2014)

Steinrucke, M.: An approach to integrate production-transportation planning and scheduling in an aluminium supply chain network. Int. J. Prod. Res. 49(21), 6559–6583 (2011)

Tang, D., Dai, M., Salido, M.A., Giret, A.: Energy-efficient dynamic scheduling for a flexible flow shop using an improved particle swarm optimization. Comput. Ind. 81, 82–95 (2015)

Viergutz, C., Knust, S.: Integrated production and distribution scheduling with lifespan constraints. Ann. Oper. Res. 213(1), 293–318 (2014)

Wang, X., Cheng, T.C.E.: Machine scheduling with an availability constraint and job delivery coordination. Naval Res. Logist. 54(1), 11–20 (2007)

Xu, X., Zhang, W., Li, N., Xu, H.: A bi-level programming model of resource matching for collaborative logistics network in supply uncertainty environment. J. Frankl. Inst. 352(9), 3873–3884 (2015)

Zegordi, S., Abadi, I., Nia, M.: A novel genetic algorithm for solving production and transportation scheduling in a two-stage supply chain. Comput. Ind. Eng. 58(3), 373–381 (2010)

Acknowledgements

This paper is supported partly by the National Natural Science Foundation of China under Grant Nos. 71532007, 71131006 and 71172197.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interests

The authors declare that they have no competing interests.

Rights and permissions

About this article

Cite this article

Yang, J., Guo, F., Luo, L. et al. Bilevel mixed-integer nonlinear programming for integrated scheduling in a supply chain network. Cluster Comput 22 (Suppl 6), 15517–15532 (2019). https://doi.org/10.1007/s10586-018-2673-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10586-018-2673-2