Abstract

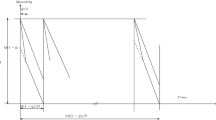

In this paper we deal with the integrated supply chain management problem in the context of a single vendor-single buyer system for which the production unit is assumed to randomly shift from an in-control to an out-of-control state. At the end of each production cycle, a corrective or preventive maintenance action is performed, depending on the state of the production unit, and a new setup is carried out. Two different integrated production, shipment and maintenance strategies are proposed to satisfy the buyer’s demand at minimum total cost. The first one suggests that the buyer orders batches of size nQ and the vendor produces nQ and makes equal shipments of size Q. The second policy proposes that to satisfy the same ordered quantity, the vendor produces separately smaller batches of size Q, n times. The total integrated average cost per time unit corresponding to each strategy is considered as the performance criterion allowing choosing the best policy for any given situation.

Similar content being viewed by others

References

Affisco J. F., Paknejad M. J., Nasri F. (2002) Quality improvement and setup reduction in the joint economic lot size model. European Journal of Operations Research 142(3): 497–508

Aghezzaf E. H., Jamali M. A., Ait-Kadi D. (2006) An integrated production and preventive maintenance planning model. European Journal of Operational Research 181(2): 679–685

Ben-Daya M. (2002) The economic production lot-sizing problem with imperfect production processes and imperfect maintenance. International Journal of Production Economics 76(3): 257–264

Ben-Daya, M., & Khursheed, S. N. (2002). The economic production lot-sizing problem with deteriorating manufacturing processes and preventive maintenance. Vaxjo, Sweden, Proceedings IFRIM.

Chelbi A., Rezg N., Radhoui M. (2008) Simultaneous determination of production lot size and preventive maintenance schedule for unreliable production system. Journal of Quality in Maintenance Engineering 14(2): 161–176

Cheng T. C. E. (1991) An economic order quantity model with demand dependent unit production cost and imperfect production processes. IIE Transactions 23(1): 23–28

Chung J. C., Wee H. M. (2008) An integrated production-inventory deteriorating model for pricing policy considering imperfect production, inspection planning and warranty-period-and stock-level-dependant demand. International Journal of Systems Science 39(8): 823–837

Goyal S. K., Huang C. K., Chen K. C. (2003) A simple integrated production policy of an imperfect item for vendor and buyer. Production Planning & Control 14(7): 596–602

Huang C. K. (2004) An optimal policy for a single-vendor single-buyer integrated production–inventory problem with process unreliability consideration. International Journal of Production Economics 91(1): 91–98

Khouja M., Mehrez A. (1994) An economic production lot size model with variable production rate and imperfect quality. Journal of the Operational Research Society 45(12): 1405–1417

Lee, H. S., & Srinivason, M. M. (2001). A production/inventory policy for an unreliable machine. In M. A. Rahim & M. Ben Daya (Eds.), Integrated models in production planning, inventory, quality, and maintenance (pp. 79–94). Kluwer Academic Publishers.

Liu X., Sila C. (2007) A note on quality improvement and setup reduction in the joint economic lot size model. European Journal of Operations Research 182(1): 194–204

Radhoui M., Rezg N., Chelbi A. (2008) Joint quality control and preventive maintenance strategy for imperfect production process. Journal of Intelligent Manufacturing 21(2): 205–212

Ritvirool A., Ferrell W. G. Jr. (2007) The effect on inventory of cooperation in single-vendor, single-buyer systems with quality considerations. International Journal of Operational Research 2(3): 338–356

Rosenblatt M. J., Lee H. L. (1986) Economic production cycles with imperfect production processes. IIE Transactions 18(1): 48–55

Sheu H., Chen J. A. (2004) Optimal lot-sizing problem with imperfect maintenance and imperfect production. International Journal of Systems Science 35(1): 69–77

Yang P. C., Wee H. M. (2002) A single-vendor and multiple-buyers production–inventory policy for a deteriorating item. European Journal of Operational Research 143(3): 570–581

Yang Z., Djurdjanovic D., Ni J. (2008) Maintenance scheduling in manufacturing systems based on predicted machine degradation. Journal of Intelligent Manufacturing 19(1): 87–98

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yedes, Y., Chelbi, A. & Rezg, N. Quasi-optimal integrated production, inventory and maintenance policies for a single-vendor single-buyer system with imperfect production process. J Intell Manuf 23, 1245–1256 (2012). https://doi.org/10.1007/s10845-010-0423-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10845-010-0423-2