Abstract

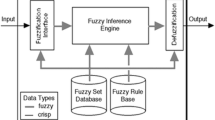

The Taguchi robust parameter design has been widely used over the past decade to solve many single-response process parameter designs. However, the Taguchi method is unable to deal with multi-response problems that are of main interest today, owing to increasing complexity of manufacturing processes and products. Several recent studies have been conducted in order to solve this problem. But, they did not effectively treat situations where responses are correlated and situations in which control factors have continuous values. This study proposed an integrated model for experimental design of processes with multiple correlated responses, composed of three stages which (1) use expert system, designed for selecting an inner and an outer orthogonal array, to design an actual experiment, (2) use Taguchi’s quality loss function to present relative significance of responses, and multivariate statistical methods to uncorrelate and synthesise responses into a single performance measure, (3) use neural networks to construct the response function model and genetic algorithms to optimise parameter design. The effectiveness of the proposed model is illustrated with three examples. Results of analysis showed that the proposed approach could yield a better solution in terms of the optimal parameters setting that results in a higher process performance measure than the traditional experimental design.

Similar content being viewed by others

References

Al-Refaie, A., Al-Tahat, M. D. (2009). Solving the multi-response problem in Taguchi method by benevolent formulation in DEA. Journal of Intelligent Manufacturing. doi:10.1007/s10845-009-0312-8.

Chang, H.-H., Chen, Y.-K. (2009). Neuro-genetic approach to optimize parameter design of dynamic multiresponse experiments. Applied Soft Computing, doi:10.1016/j.asoc.2009.12.002.

Chen W.-C., Fu G.-L., Tai P.-H., Deng W.-J. (2009) Process parameter optimization for MIMO plastic injection molding via soft computing. Expert Systems with Application 36(2): 1114–1122

Fung C. P., Kang P. C. (2005) Multi-response optimization in friction properties of PBT composites using Taguchi method and principle component analysis. Journal of Materials Processing Technology 170: 602–610

Holden T., Serearuno M. (2005) A hybrid artificial intelligence approach for improving yield in precious stone manufacturing. Journal of Intelligent Manufacturing 16: 21–38

Hou T. H., Chen S. H., Lin T. Y., Huang K. M. (2006) An integrated system for setting the optimal parameters in IC chip-package wire bonding processes. International Journal of Advanced Manufacturing Technology 30: 247–253

Hsieh K. L. (2006) Parameter optimization of a multi-response process for lead frame manufacturing by employing artificial neural networks. International Journal of Advanced Manufacturing Technology 28: 584–591

Hsu C. M., Su C. T., Liao D. (2004) Simultaneous optimisation of the broadband tap coupler optical performance based on neural networks and exponential desirability functions. International Journal of Advanced Manufacturing Technology 23(11–12): 896–902

Huang C. C., Tang T. T. (2006) Parameter optimization in melt spinning by neural networks and genetic algorithms. International Journal of Advanced Manufacturing Technology 27: 1113–1118

Lau H. C. W., Lee C. K. M., Ip W. H., Chan F. T. S., Leung R. W. K. (2005) Design and implementation of a process optimizer: A case study on monitoring molding operations. Expert Systems 22(1): 12–21

Liao H. C. (2005) Using N-D method to solve multi-response problem in Taguchi. Journal of Intelligent Manufacturing 16: 331–347

Liao H. C. (2006) Multi-response optimization using weighted principal component. International Journal of Advanced Manufacturing Technology 27(7–8): 720–725

Liau L. C.-K., Yang T. C.-K., Tsai M.-T. (2004) Expert system of a crude oil distillation unit for process optimization using neural networks. Expert Systems with Applications 26: 247–255

Malakooti B., Raman V. (2000) An interactive multi-objective artificial neural network approach for machine setup optimization. Journal of Intelligent Manufacturing 11: 41–50

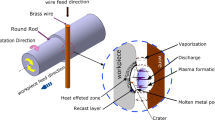

Markopoulos A., Manolakos D., Vaxevanidis N. (2008) Artificial neural network models for the prediction of surface roughness in electrical discharge machining. Journal of Intelligent Manufacturing 19: 283–292

Mok C. L., Kwong C. K., Lau W. S. (2000) An intelligent hybrid system for initial process parameter setting of injection moulding. International Journal of Production Research 38(17): 4565–4576

Myers R. H., Montgomery D. C. (2002) Response surface methodology: Process and product optimization using designed experiments. John Wiley & Sons, New York

Noorossana R., Davanloo Tajbakhsh S, Saghaei A. (2008) An artificial neural network approach to multiple-response optimization. International Journal of Advanced Manufacturing Technology 40(11–12): 1227–1238

Ortiz F., Simposon J. R., Pigatiello J. J., Heredia-Lagner A. (2004) A genetic algorithm approach to multi-response optimisation. Journal of Quality Technology 36: 432–450

Roy R., Mehnen J. (2008) Dynamic multi-objective optimisation for machining gradient materials. Annals of the CIRP 57: 429–432

Sedighi, M., & Afshari, D. (2009). Creep feed grinding optimization by an integrated GA-NN system. Journal of Intelligent Manufacturing. doi:10.1007/s10845-009-0243-4.

Sibalija T., Majstorovic V. (2009) Multi-response optimisation of thermosonic copper wire-bonding process with correlated responses. International Journal of Advanced Manufacturing Technology 42(3–4): 363–371

Sibalija, T. (2009). Development of an intelligent designer of experiment model for application of Taguchi method. PhD Thesis, Faculty of Mechanical Engineering, University of Belgrade.

Su C. T., Tong L. I. (1997) Multi-response robust design by principal component analysis. Total Quality Management 8(6): 409–416

Su C. T., Chiang T. L. (2003) Optimizing the IC wire bonding process using a neural networks/genetic algorithms approach. Journal of Intelligent Manufacturing 14: 229–238

Taguchi G. (1986) Introduction to quality engineering. Asian Productivity Organization. UNIPUB, New York

Tomić B., Jovanović J., Devedžić V. (2006) JavaDON: An open-source expert system shell. Expert Systems with Applications 31: 595–606

Tong K. W., Kwong C. K., Yu K. M. (2004) Intelligent process design system for the transfer moulding of electronic packages. International Journal of Production Research 42(10): 1911–1931

Wang C. H., Tong L. I. (2005) Optimization of dynamic multi-response problems using grey multiple attribute decision making. Quality Engineering 17(1): 1–9

Wang, G., Wang, Y., Zhao J., & Chen G. (2009). Process optimization of the serial-parallel hybrid polishing machine tool based on artificial neural network and genetic algorithm. Journal of Intelligent Manufacturing. doi:10.1007/s10845-009-0376-5.

Wu F. C. (2004) Optimising robust design for correlated quality characteristics. International Journal of Advanced Manufacturing Technology 24(1–2): 1–8

Yang T. C. K., Tsai M. T. (2004) A neurofuzzy-based quality-control system for fine pitch stencil printing process in surface mount assembly. Journal of Intelligent Manufacturing 15(5): 711–721

Yu J. C., Chen X. X., Hung T. R., Thibault F. (2004) Optimization of extrusion blow molding processes using soft computing and Taguchi’s method. Journal of Intelligent Manufacturing 15: 625–634

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sibalija, T.V., Majstorovic, V.D. An integrated approach to optimise parameter design of multi-response processes based on Taguchi method and artificial intelligence. J Intell Manuf 23, 1511–1528 (2012). https://doi.org/10.1007/s10845-010-0451-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10845-010-0451-y