Abstract

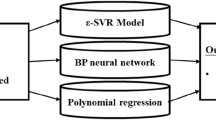

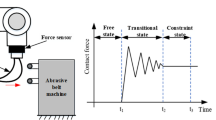

As a kind of manufacturing system with a flexible grinder, the material removal of a robot belt grinding system is related to a variety of factors, such as workpiece shape, contact force, robot velocity, and belt wear. Some factors of the grinding process are time-variant. Therefore, it is a challenge to control grinding removal precisely for free-formed surfaces. To develop a high-quality robot grinding system, an off-line planning method for the control parameters of the grinding robot based on an adaptive modeling method is proposed in this paper. First, we built an adaptive model based on statistic machine learning. By transferring the old samples into the new samples space formed by the in-situ measurement data, the adaptive model can track the dynamic working conditions more rapidly. Based on the adaptive model the robot control parameters are calculated using the cooperative particle swarm optimization in this paper. The optimization method aims to smoothen the trajectories of the control parameters of the robot and shorten the response time in the transition process. The results of the blade grinding experiments demonstrate that this approach can control the material removal of the grinding system effectively.

Similar content being viewed by others

References

Caydas, U., & Ekici, S. (2010). Support vector machines models for surface roughness prediction in CNC turning of AISI 304 austenitic stainless steel. Journal of Intelligent Manufacturing. doi:10.1007/s10845-010-0415-2

Chen, X., Gong, Z., & Huang, H. (2000). Development of robotic system for 3D profile grinding and polishing. SIMTech Technical Report: AT/00/012/AMP.

Cortes C., Vapnik V. (1995) Support vector network. Machine Learning 20: 273–297

Huang H., Gong Z. M., Chen X. Q., Zhou L. (2002) Robotic grinding and polishing for turbine-vane overhaul. Journal of Materials Processing Technology 127: 140–145

Kennedy, J., & Eberhart, R. (1995). Particle swarm optimization. Proceedings of the IEEE International Conference on Neural Networks, 1942–1948.

Maksoud T. M. A., Atia M. R., Koura M. M. (2003) Applications of artificial intelligence to grinding operations via neural networks. Machining Science and Technology 7: 361–387

Ren X., Kuhlenkoetter B. (2008) Real-time simulation and visualization of robotic belt grinding processes. The International Journal of Advanced Manufacturing Technology 35: 1090–1099

Ren X., Cabaravdic M., Zhang X., Kuhlenkoetter B. (2007) A local process model for simulation of robotic belt grinding. International Journal of Machine Tools and Manufacture 47: 962–970

Sedighi, M., & Afshari, D. (2010). Creep feed grinding optimization by an integrated GA-NN system. Journal of Intelligent Manufacturing. doi:10.1007/s10845-009-0243-4

Shi D., Gindy N. N. (2007) Tool wear predictive model based on least squares support vector machines. Mechanical Systems and Signal Processing 21: 1799–1814

Sun, Y. (2004). Development of a unified flexible grinding process. Doctoral Dissertation, The University of Connecticut.

Takahashi, J., & Sagayama, S. (1995). Vector-field-smoothed Bayesian learning for incremental speaker adaptation. In Proceedings of the IEEE internaltional conference on acoustics, speech, and signal processing (pp. 696–699).

Toy F. E. H., Cao L. J. (2002) Modified support vector machines in financial time series forecasting. Neurocomputing 48: 847–861

van den Bergh F., Engelbrecht A. P. (2004) A cooperative approach to particle swarm optimization. IEEE Transactions on Evolutionary Computation 8: 225–239

Vapnik V. (1998) Statistical leaning theory. Springer, New York

Wang X. Y., Wang W., Huang Y., Nguyen N., Krishnakumar K. (2008) Design of neural network-based estimator for tool wear modeling in hard turning. Journal of intelligent manufacturing 19: 383–396

Zhang X., Cabaravdic M., Kneupner K., Kuhlenkoetter B. (2004) Real-time simulation of robot controlled belt grinding processes of sculptured surfaces. International Journal of Advanced Robotic Systems 1: 109–114

Zhao, Y., Zhao, J., Zhang, L., & Qi, L. Z. (2008). Development of a robotic 3D scanning system for reverse engineering of freeform part. In Proceedings of the international conference on advanced computer theory and engineering (pp. 246–250).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Song, Y., Liang, W. & Yang, Y. A method for grinding removal control of a robot belt grinding system. J Intell Manuf 23, 1903–1913 (2012). https://doi.org/10.1007/s10845-011-0508-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10845-011-0508-6