Abstract

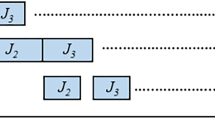

This paper considers a two-stage hybrid flowshop scheduling problem in machine breakdown condition. By machine breakdown condition we mean that the machine may not always be available during the scheduling period. Machine failure may occur with a known probability after completing a job. Probability of machine failure depends on the previous processed job. The problem to be studied has one machine at the first stage and M parallel identical machines at the second stage. The objective is to find the optimal job combinations and the optimal job schedule such that the makespan is minimized. The proposed problem is compatible with a large scope of real world situations. To solve the problem, first, we introduce one optimal approach for job precedence when there is one machine in both stages and then provide a heuristic algorithm when there are M machines in stage two. To examine the performance of the heuristic, some experiments used are provided as well.

Similar content being viewed by others

References

Allahverdi A., Ng C. T., Cheng T. C. E., Kovalyov M. Y. (2008) A survey of scheduling problems with setup times or costs. European Journal of Operational Research 187: 985–1032

Botta-Genoulaz V. (2000) Hybrid flow shop scheduling with precedence constraints and time lags to minimize maximum lateness. International Journal of Production Economics 64: 101–111

Brah S. A., Loo L. L. (1999) Heuristics for scheduling in a flow shop with multiple processors. European Journal of Operational Research 113: 113–122

Cai X., Zhou X. (2000) Asymmetric earliness and tardiness scheduling with exponential processing times on an unreliable machine. Annals of Operations Research 98: 313–331

Cai, X., Wu, X., & Zhou, X. (in press). Scheduling deteriorating jobs on a single machine subject to breakdowns. Journal of Scheduling. doi:10.1007/s10951-009-0132-x.

Engin O., Döyen A. (2004) A new approach to solve hybrid flow shop scheduling problems by artificial immune system. Future Generation Computer Systems 20: 1083–1095

Gholami M., Zandieh M. (2009) Integrating simulation and genetic algorithm to schedule a dynamic flexible job shop. Journal of Intelligent Manufacturing 20: 481–498

Guinet A., Solomon M. M., Kedia P. K., Dussauchoy A. (1996) A computational study of heuristics for two-stage flexible flowshop. International Journal of Production Research 34: 1399–1415

Gupta J. N. D. (1988) Two stage, hybrid flowshop scheduling problem. Journal of the Operational Research Society 39: 359–364

Gupta J. N. D., Tunc E. A. (1991) Schedules for a two-stage hybrid flowshop with parallel machines at the second stage. International Journal of Production Research 29: 1489–1502

Gupta J. N. D., Krüger K., Lauff V., Werner F., Sotskov Y. N. (2002) Heuristics for hybrid flow shops with controllable processing times and assignable due dates. Computers & Operations Research 29: 1417–1439

Johnson S. M. (1954) Optimal two- and three-stage production schedules with setup times included. Naval Research Logistics Quarterly 1: 61–68

Lee Y. (1996) Machine scheduling with an availability constraint. Journal of Global Optimization 9: 395–416

Lin H. T., Liao C. J. (2003) A case study in a two-stage hybrid flow shop with setup time and dedicated machines. International Journal of Production Economics 86: 133–143

Linn R., Zhang W. (1999) Hybrid flow shop scheduling: A survey. Computers & Industrial Engineering 37: 57–61

Low C., Hsu C. J., Su C. T. (2008) A two-stage hybrid flowshop scheduling problem with a function constraint and unrelated alternative machines. Computers & Operations Research 35: 845–853

Luxhoj J., Shyur H. (1997) Comparison of proportional hazards models and neural networks for reliability estimation. Journal of Intelligent Manufacturing 8: 227–234

Mirsanei, H. S., Zandieh, M., Moayed, M. J., & Khabbazi, M. R. (in press). A simulated annealing algorithm approach to hybrid flow shop scheduling with sequence-dependent setup times. Journal of Intelligent Manufacturing. doi:10.1007/s10845-009-0373-8.

Moursli O., Pochet Y. (2000) A branch-and-bound algorithm for the hybrid flowshop. International Journal of Production Economics 64: 113–125

Nawaz M., Enscore E. E., Ham I. (1983) A heuristic algorithm for the m-machine, n-job flowshop sequencing problem. Omega 11: 91–95

Riezebos J. G. J. C., Gaalman G. J. C., Gupta J. N. D. (1995) Flow shop scheduling with multiple operations and time lags. Journal of Intelligent Manufacturing 6: 105–115

Ríos-Mercado R. Z., Bard J. F. (1999a) A branch-and-bound algorithm for permutation flowshops with sequence-dependent setup times. IIE Transactions 31: 721–731

Ríos-Mercado R. Z., Bard J. F. (1999b) An enhanced TSP-based heuristic for makespan minimization in a flowshop with setup times. Journal of Heuristics 5: 53–70

Ruiz R., Maroto C., Alcaraz J. (2005) Solving the flowshop scheduling problem with sequence dependent setup times using advanced metaheuristics. European Journal of Operational Research 165: 34–54

Ruiz R., Maroto C. (2006) A genetic algorithm for hybrid flowshops with sequence dependent setup times and machine eligibility. European Journal of Operational Research 169: 781–800

Ruiz R., Stutzle T. (2008) An iterated greedy heuristic for the sequence dependent setup times flowshop with makespan and weighted tardiness objectives. European Journal of Operational Research 187: 1143–1159

Santos D. L., Hunsucker J. L., Deal D. E. (1995) Flowmult: Permutation sequences for flow shops with multiple processors. Journal of Information and Optimization Sciences 16: 351–366

Sheen G., Liao L., Lin C. (2008) Optimal parallel machines scheduling with machine availability and eligibility constraints. International Journal of Advanced Manufacturing Technology 36: 132–139

Su L. (2003) A hybrid two-stage flowshop with limited waiting time constraints. Computers & Industrial Engineering 44: 409–424

Tang H., Zhao C. (2007) Stochastic single machine scheduling subject to machines breakdowns with quadratic early-tardy penalties for the preemptive-repeat model. Journal of Applied Mathematics and Computing 25: 183–199

Tang L., Liu W., Liu J. (2005) A neural network model and algorithm for the hybrid flow shop scheduling problem in a dynamic environment. Journal of Intelligent Manufacturing 16: 361–370

Tang L., Xuan H., Liu J. (2006) A new Lagrangian relaxation algorithm for hybrid flowshop scheduling to minimize total weighted completion time. Computers & Operations Research 33: 3344–3359

Tseng, C. T., Liao C. J., & Liao T. X. (in press). A note on two-stage hybrid flowshop scheduling with missing operations. Computers & Industrial Engineering. doi:10.1016/j.cie.2007.09.005.

Vob S., Witt A. (2007) Hybrid flow shop scheduling as a multi-mode multi-project scheduling problem with batching requirements: A real-world application. International Journal of Production Economics 105: 445–458

Wu B., Seddon J. M. (1994) An anthropocentric approach to knowledge-based preventive maintenance. Journal of Intelligent Manufacturing 5: 389–397

Yang Y., Kreipl S., Pinedo M. (2000) Heuristics for minimizing total weighted tardiness in flexible flowshop. Journal of Scheduling 3: 71–88

Yong T., Chuanli Z., Dian C. (2008) Single machine stochastic JIT scheduling problem subject to machine breakdowns. Science in China Series A: Mathematics 51: 273–292

Zandieh, M., Mozaffari, E., & Gholami, M. (in press). A robust genetic algorithm for scheduling realistic hybrid flexible flow line problems. Journal of Intelligent Manufacturing. doi:10.1007/s10845-009-0250-5.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mirabi, M., Ghomi, S.M.T.F. & Jolai, F. A two-stage hybrid flowshop scheduling problem in machine breakdown condition. J Intell Manuf 24, 193–199 (2013). https://doi.org/10.1007/s10845-011-0553-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10845-011-0553-1