Abstract

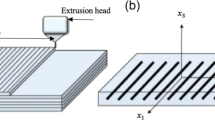

This paper discusses a systematic approach to implement the principles of Flat Pattern Analysis FPA for folding sheet metal products. The paper starts by highlighting the needs for the vehicular structure forming process with respect to the main production line requirements through using Quality Function Deployment QFD matrix. Additionally, the potentials of fold forming for sheet metal parts in achieving the major production needs will then be benchmarked against other forming techniques through a decision making tool namely; the Analytical Hierarchy Process AHP. The study investigates the application of flat pattern tools for sheet metal products derived from analysis for thin or zero thickness sheets (i.e. paper origami). The analysis sets an approach to generate all possible configurations of flat patterns that result in a specific 3-D structure profile. Secondly, a set of optimality selection metrics are developed and applied to these configurations to help determine the most optimized flat pattern. These optimality measures are a metric based on compactness, a metric for nesting efficiency to describe the strip layout planning, and two measures to assess the manufacturing aspect i.e. bending operation in terms of number and orientation of bend lines.

Similar content being viewed by others

References

Balas E., Perregaard M. (2002) Lift-and-project for mixed 0-1 programming: Recent progress. Discrete Applied Mathematics 123: 129–154

Balkcom, D., & Mason, M. (2004). Introducing robotic origami folding. In Proceedings of IEEE international conference on robotics and automation, New Orleans, LA (pp. 3245–3250).

Bern, M., & Hayes, B. (1996). The complexity of flat origami. In Proceedings of the 7th annual ACM-SIAM symposium on discrete algorithms, Atlanta, GA (pp. 175–183).

Boljanovic V. (2004) Sheet metal forming process and die design. Industrial Press, New York

Chang, F. C., & Huang, H. C. (2010). A refactoring method for cache-efficient swarm intelligence algorithms. Information Sciences doi:10.1016/j.ins.2010.02.025.

Chen S. C., Yang C. C., Lin W. T., Yeh T. M., Lin Y. S. (2007) Construction of key model for knowledge management system using AHP-QFD for semiconductor industry in Taiwan. Journal of Manufacturing Technology Management 18: 576–598

Dai J., Rees Jones J. (1999) Mobility in metamorphic mechanisms of foldable/erectable kinds. ASME Journal of Mechanical Design 121: 375–382

Elsayed E., Basily B. (2004) A continuous folding process for sheet materials. International Journal of Materials and Product Technology 21: 217–238

Even S. (1979) Graph algorithms. Pitman Publishing Limited, London

Hambali A., Sapuan S. M., Ismail N., Nukman Y. (2009) Application of the analytical hierarchy process in the design concept selection of automotive composite bumper beam during the conceptual design stage. Scientific Research and Essay 4: 198–211

Hull, T. (1994). On the mathematics of flat origami’s. In The proceedings of the southeastern international conference on combinatorics, graph theory & computing, Boca Raton, FL (pp. 215–224).

Hull T. (1996) A Note on ‘impossible’ paper folding. American Mathematical Monthly 103(3): 240–241

Kaganami H. G., Ali S. K., Zou B. (2011) Optimal approach for texture analysis and classification based on wavelet transform and neural network. Journal of Information Hiding and Multimedia Signal Processing 2(1): 33–40

Kalpakjian S., Schmidt S. (2006) Manufacturing engineering and technology. Prentice Hall, New Jersey

Lang, R. (1996). A computational algorithm for origami design. In The proceedings of the 12th annual ACM symposium on computational geometry, Philadelphia (pp. 98–105).

Lee, Y., Tor, S., & Soo, E. (1996). Mathematical modeling and simulation of pop- up books. Computer and Graphics, 20(1), 21–31.

Lin Y. L., Yang D. C. H. (1994) Automatic development generation for thin-walled objects. ASME In Advances in Design Automation 1: 367–377

Lin, Y., & Yang, D. (1998). Flat pattern generation of thin-walled objects based on a mechanism theory. In Proceedings of the Institution of Mechanical Engineers-Part B-Journal of Engineering Manufacture, 212(4), 325–334.

Lipson H., Shpitalni M. (1998) On the topology of sheet metal parts. ASME Journal of Mechanical Design 120: 120–130

Liu, H., & Dai, J. S. (2002). Carton manipulation analysis using configuration transformation. In Proceedings of the institution of mechanical engineers. Part C: Journal of Mechanical Engineering Science, 216, 543–555.

Liu, W., & Tai, K. (2002). Computational geometric modeling and unfolding of 3-D folded structures. In The proceedings of the ASME design engineering technical conferences (28th design automation conference), Paper no. DETC2002/DAC-34046.

Liu W., Tai K. (2007) Optimal design of flat patterns for 3D folded structures by unfolding with topological validation. Computer-Aided Design 39: 898–913

Mayyas A., Shen Q., Mayyas A., Abdelhamid M., Shan D., Qattawi A. et al (2011) Using quality function deployment and analytical hierarchy process for material selection of body-in-white. Materials and Design 32: 2771–2782

Omar M. A., Zhou Y. (2008) Dynamic-template processing for passive thermograms: Applied to automotive stamping split-detection. International Journal of nondestructive testing and evaluation 41: 582–588

Onwubolu G. C., Mutingi M. (2003) A genetic algorithm approach for the cutting stock problem. Journal of Intelligent Manufacturing 14(2): 209–218

Poshyanonda P., Dagli C. H. (2004) Genetic neuro-nester. Journal of Intelligent Manufacturing 15(2): 201–218

Puranik P., Bajaj P., Abraham A., Palsodkar P., Deshmukh A. (2011) Human perception-based color image segmentation using comprehensive learning particle swarm optimization. Journal of Information Hiding and Multimedia Signal Processing 2(3): 227–235

Shioura A., Tamura A., Uno T. (1997) An optimal algorithm for scanning all spanning trees of undirected graphs. Journal on Computing 26(3): 678–692

Shpitalni M. (1993) A new concept for design of sheet metal products. CIRP 42(1): 123–126

Shpitalni M., Lipson H. (2000) 3D conceptual design of sheet metal products by sketching. Journal of Materials Processing Technology 103: 128–134

Silva M. B., Baptista R. M. S. O., Martins P. A. F. (2003) Stamping of automotive components: A numerical and experimental investigation. Journal of Materials Processing Technology 155–156: 1489–1496

Tai K., Liu W., Thimm G. (2004) Unfolding and flat layout design of non-manifold 3D folded structures. Computer-Aided Design and Applications 1(1–4): 439–447

Tanaka, K., Kamotani, Y., & Yokoko, Y. (2007). Origami folding by a robotic hand. In The Proceedings of the 2007 IEEE/RSJ international conference on intelligent robots and systems, San Diego, CA (pp. 208–213).

Távora J., Coelho H. (1989) A path planner for the cutting of nested irregular layouts. Lecture Notes in Computer Science 390: 246–256

Thiruvengadam, H. (2010). Analysis of part consolidation techniques for automotive BIW panels based on advanced sheet metal forming technologies. Master Thesis, Clemson University.

Vijayakumar, S. (2010). Analysis of alternative manufacturing processes for lightweight BIW designs, using analytical hierarchy process. Master Thesis, Clemson University.

Wang, C. H. (1997). Manufacturing-driven decomposition of sheet metal products. Ph.D. Thesis, Carnegie Mellon University.

Yao W., Cannella F., Dai J. (2011) Automatic folding of cartons using a reconfigurable robotic system. Robotics and Computer-Integrated Manufacturing 27(3): 604–613

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Qattawi, A., Mayyas, A., Thiruvengadam, H. et al. Design considerations of flat patterns analysis techniques when applied for folding 3-D sheet metal geometries. J Intell Manuf 25, 109–128 (2014). https://doi.org/10.1007/s10845-012-0679-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10845-012-0679-9