Abstract

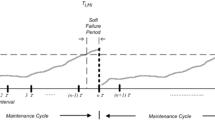

In this paper a condition-based maintenance model is proposed for a single-unit system of production of goods and services. The system is subject to random deterioration which impacts not only the product quality but also the environment. We assume that the environment degrades whenever a specific level of system deterioration is reached. The proposed maintenance model aims to assess the degradation in such a way to reduce the deterioration of the environment. To control this deterioration, inspections are performed and after which the system is preventively replaced or left as it is. Preventive replacement occurs whenever the level of the system degradation reaches a specific level threshold. The objective is to determine optimal inspection dates which minimize the average total cost per unit of time in the infinite horizon. Cost function is composed of inspection and maintenance costs in addition to a penalty cost due to environmental deterioration. The maintenance optimization model is formally derived. On the basis of Nelder–Mead method, inspection dates as optimal solutions are computed. A numerical example is provided to illustrate the proposed maintenance model.

Similar content being viewed by others

References

Aït-Kadi, D.,& Chelbi, A. (2010). Inspection strategy for availability improvement. Journal of Intelligent Manufacturing, 21(2), 231–235.

Badía, F., Berrade, M.,& Campos, C. A. (2002). Optimal inspection and preventive maintenance of units with revealed and unrevealed failures. Reliability Engineering& System Safety, 78(2), 157–163.

Barlow, R. E., Hunter, L. C.,& Proschan, F. (1963). Optimum checking procedures. Journal of the Society for Industrial and Applied Mathematics, 11(4), 1078–1095.

Bérenguer, C., Chu, C.,& Grall, A. (1997). Inspection and maintenance planning: An application of semi-Markov decision processes. Journal of Intelligent Manufacturing, 8(5), 467–476.

Bui, L. T.,& Kapon, S. (2012). The impact of voluntary programs on polluting behavior: Evidence from pollution prevention programs and toxic releases. Journal of Environmental Economics and Management, 64(1), 31–44.

Chelbi, A.,& Aït-Kadi, D. (1999). An optimal inspection strategy for randomly failing equipment. Reliability Engineering& System Safety, 63(2), 127–131.

Chelbi, A.,& Aït-Kadi, D. (2009). Inspection strategies for randomly failing systems. In M. Ben-Daya, S. O. Duffuaa, A. Raouf, J. Knezevic, D. Aït-Kadi (Eds.), Handbook of maintenance management and engineering (pp. 303–335). London: Springer.

Chelbi, A., Aït-Kadi, D.,& Aloui, H. (2008). Optimal inspection and preventive maintenance policy for systems with self-announcing and non-self-announcing failures. Journal of Quality in Maintenance Engineering, 14(1), 34–45.

Cui, L.,& Xie, M. (2005). Availability of a periodically inspected system with random repair or replacement times. Journal of Statistical Planning and Inference, 131(1), 89–100.

Grall, A., Dieulle, L., Bérenguer, C.,& Roussignol, M. (2002). Continuous-time predictive-maintenance scheduling for a deteriorating system. IEEE Transactions on Reliability, 51(2), 141–150.

Harrington, D. R. (2012). Two-stage adoption of different types of pollution prevention (P2) activities. Resource and Energy Economics, 34(3), 349–373.

Huynh, K., Barros, A., Bérenguer, C.,& Castro, I. (2011). A periodic inspection and replacement policy for systems subject to competing failure modes due to degradation and traumatic events. Reliability Engineering& System Safety, 96(4), 497–508.

Joshi, P., Imadabathuni, M., He, D., Al-Kateb, M.,& Bechhoefer, E. (2012). Application of the condition based maintenance checking system for aircrafts. Journal of Intelligent Manufacturing, 23(2), 277–288.

Lagarias, J. C., Reeds, J. A., Wright, M. H.,& Wright, P. E. (1998). Convergence properties of the Nelder-Mead simplex method in low dimensions. SIAM Journal on Optimization, 9(1), 112–147.

Li, W.,& Pham, H. (2005). An inspection-maintenance model for systems with multiple competing processes. IEEE Transactions on Reliability, 54(2), 318–327.

Liao, H., Elsayed, E. A.,& Chan, L. (2006). Maintenance of continuously monitored degrading systems. European Journal of Operational Research, 175(2), 821–835.

Munford, A. G.,& Shahani, A. K. (1972). A nearly optimal inspection policy. Operational Research Quarterly, 23(3), 373–379.

Munford, A. G.,& Shahani, A. K. (1973). An inspection policy for the weibull case. Operational Research Quarterly, 24(3), 453–458.

Nelder, J. A.,& Mead, R. (1965). A simplex method for function minimization. The Computer Journal, 7(4), 308–313.

Orth, P., Yacout, S.,& Adjengue, L. (2012). Accuracy and robustness of decision making techniques in condition based maintenance. Journal of Intelligent Manufacturing, 23(2), 255–264.

Pellegrin, C. (1992). Choice of a periodic on-condition maintenance policy. International Journal of Production Research, 30(5), 1153–1173.

Price, C., Coope, I.,& Byatt, D. (2002). A convergent variant of the nelder-mead algorithm. Journal of Optimization Theory and Applications, 113(1), 5–19.

Roux, O., Duvivier, D., Quesnel, G.,& Ramat, E.: Optimization of preventive maintenance through a combined maintenance-production simulation model. International Journal of Production Economics (2010). doi:10.1016/j.ijpe.2010.11.004.

Sarkar, J.,& Sarkar, S. (2000). Availability of a periodically inspected system under perfect repair. Journal of Statistical Planning and Inference, 91(1), 77–90.

Sharma, A., Yadava, G.,& Deshmukh, S. (2011). A literature review and future perspectives on maintenance optimization. Journal of Quality in Maintenance Engineering, 17(1), 5–25.

Tadikamalla, P. R. (1979). An inspection policy for the gamma failure distributions. The Journal of the Operational Research Society, 30(1), 77–80.

Tian, Z., Lin, D.,& Wu, B. (2012). Condition based maintenance optimization considering multiple objectives. Journal of Intelligent Manufacturing, 23(2), 333–340.

Turco, F.,& Parolini, P. (1984). A nearly optimal inspection policy for productive equipment. International Journal of Production Research, 22(3), 515–528.

Yang, Z., Djurdjanovic, D.,& Ni, J. (2008). Maintenance scheduling in manufacturing systems based on predicted machine degradation. Journal of Intelligent Manufacturing, 19(1), 87–98.

Author information

Authors and Affiliations

Corresponding author

A Appendix

A Appendix

A.1 Proof of Proposition 2

Let us recall that inspections are carried out until the degradation level exceeds the given level \(L\). It follows that the number \(N\) of inspections during a cycle is a geometric random variable whose expectation is such that:

where \(Pr\left\{ N=i\right\} \) is the probability of performing exactly \(i\) inspection actions during a cycle. To calculate such a probability, let us note that:

which implies that:

The event \(^{\prime \prime }N< i^{\prime \prime }\) is equivalent to the fact that the cycle ends with a corrective maintenance, i.e. the production system fails before the \(i^{th}\) inspection date \(\theta _i\). Under the assumption that the production system fails only after exceeding the threshold level of environmental degradation, the event \(^{\prime \prime }N< i^{\prime \prime }\) is equivalent to \(^{\prime \prime }T+X< \theta _i^{\prime \prime }\). Consequently, for all \(i\) we have:

Since random variable \(X\) is assumed to be the residual lifetime of the production system after exceeding the alarm threshold, it follows that:

As a result, we have:

This ends the proof.

A.2 Proof of Proposition 3

Let us assume that the degradation level exceeds the threshold value \(L\) at \(T=\tau \), and \(\theta _{i-1} < T \le \theta _{i} \). It follows that duration \(T_d\) of excessive environmental degradation in a cycle could be written as:

In other words, \(T_d = min(X, \theta _i+H-\tau )\). The average time \(E(T_d)\) of excessive environmental degradation in a cycle can be expressed as:

This ends the proof.

A.3 Proof of Proposition 4

To prove Proposition 4, let us note that the cycle time represented by the random variable \(T_c\) can be written as:

It follows that the average cycle time \(E(T_c)\) is:

By exploiting the result of Proposition 3, the average cycle time \(E(T_c)\) can be written as:

This ends the proof.

Rights and permissions

About this article

Cite this article

Chouikhi, H., Khatab, A. & Rezg, N. A condition-based maintenance policy for a production system under excessive environmental degradation. J Intell Manuf 25, 727–737 (2014). https://doi.org/10.1007/s10845-012-0715-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10845-012-0715-9