Abstract

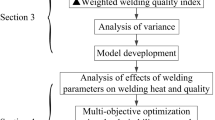

This paper investigates the effects of welding parameters on the welding quality and optimizes them in the small scale resistance spot welding (SSRSW) process. Experiments are carried out on the basis of response surface methodology technique with different levels of welding parameters of spot welded titanium alloy sheets. Multiple quality characteristics, namely signal-to-noise (S/N) ratios of weld nugget diameter, penetration rate, tensile shear load and the failure energy, are converted into an independent quality index using principal component analysis. The mathematical model correlating process parameters and their interactions with the welding quality is established and discussed. And then this model is used to select the optimum process parameters to obtain the desired welding quality. The verification test results demonstrate that the method presented in this paper to optimize the welding parameters and enhance the welding performance is effective and feasible in the SSRSW process.

Similar content being viewed by others

References

Aghaei, J., Ara, A. L., & Shabani, M. (2012). Fuzzy multi-objective optimal power flow considering UPFC. International Journal of Innovative Computing, Information and Control, 8, 1155–1166.

Antony, J. (2000). Multi-response optimization in industrial experiments using Taguchi’s quality loss function and principal component analysis. Quality and Reliability Engineering International, 16, 3–8.

Antony, J. (2001). Simultaneous optimization of multiple quality characteristics in manufacturing processes using Taguchi’s Quality Loss Function. International Journal of Advanced Manufacturing Technology, 17, 134–138.

Aslan, N., & Cebeci, Y. (2007). Application of Box–Behnken design and response surface methodology for modeling of some Turkish coals. Fuel, 86, 90–97.

Aslanlar, S. (2006). The effect of nucleus size on mechanical properties in electrical resistance spot welding of sheets used in automotive industry. Materials & Design, 27, 125–131.

Bai, R., & Chai, T. (2012). Hybrid intelligent optimal-setting control with multi-objectives of the raw slurry blending process in the alumina production. International Journal of Innovative Computing, Information and Control, 8, 1251–1262.

Beal, V. E., Erasenthiran, P., Hopkinson, N., Dickens, P., & Ahrens, C. H. (2006). Optimization of processing parameters in laser fused H13/Cu materials using response surface method (RSM). Journal of Materials Processing Technology, 174, 145–154.

Chen, Y. C., Tseng, K. H., & Cheng, Y. S. (2012). Electrode displacement and dynamic resistance during small-scale resistance spot welding. Advanced Science Letters, 11, 72–79.

Cui, C., Hu, B. M., Zhao, L., & Liu, S. (2011). Titanium alloy production technology, market prospects and industry development. Materials & Design, 32, 1684–1691.

Darwish, S. M., & Al-Dekhial, S. D. (1999). Statistical models for spot welding of commercial aluminum sheets. International Journal of Machine Tools and Manufacture, 39, 1589–1610.

Ding, L., Tan, J., Wei, Z., Chen, W., & Gao, Z. (2011). Multi-objective performance design of injection molding machine via a new multi-objective optimization algorithm. International Journal of Innovative Computing, Information and Control, 7, 3939–3950.

Dong, S. J., Kelkar, G. P., & Zhou, Y. (2002). Electrode sticking during micro-resistance welding of thin metal sheets. IEEE Transactions on Electronics Packaging Manufacturing, 25, 355–361.

Dubey, A. K., & Yadava, V. (2008). Robust parameter design and multi-objective optimization of laser beam cutting for aluminium alloy sheet. The International Journal of Advanced Manufacturing Technology, 38, 268–277.

Ely, K. J., & Zhou, Y. (2001). Microresistance spot welding of Kovar, steel, and nickel. Science and Technology of Welding & Joining, 6, 63–72.

Esme, U. (2009). Application of Taguchi method for the optimization of resistance spot welding process. The Arabian Journal for Science and Engineering, 34, 519–528.

Ferreira, S. L. C., Bruns, R. E., Ferreira, H. S., Matos, G. D., David, J. M., Brandao, G. C., et al. (2007). Box-Behnken design: An alternative for the optimization of analytical methods. Analytica Chimica Acta, 597, 179–186.

Fukumoto, S., Fujiwara, K., Toji, S., & Yamamoto, A. (2008). Small-scale resistance spot welding of austenitic stainless steels. Materials Science and Engineering A, 492, 243–249.

Fung, H. C., & Kang, P. C. (2005). Multi-response optimization in friction properties of PBT composites using Taguchi method and principal component analysis. Journal of Materials Processing Technology, 170, 602–610.

Hameed, B. H., Lai, L. F., & Chin, L. H. (2009). Production of biodiesel from palm oil (Elaeis guineensis) using heterogeneous catalyst: An optimized process. Fuel Processing Technology, 90, 606–610.

Hernandez, V. H. B., Kuntz, M. L., Khan, M. I., & Zhou, Y. (2008). Influence of microstructure and weld size on the mechanical behavior of dissimilar AHSS resistance spot welds. Science and Technology of Welding and Joining, 13, 769–776.

Islam, M. A., Sakkas, V., & Albanis, T. A. (2009). Application of statistical design of experiment with desirability function for the removal of organophosphorus pesticide from aqueous solution by low-cost material. Journal of Hazardous Materials, 170, 230–238.

Kaiser, J. G., Dunn, G. J., & Eagar, T. W. (1982). Effect of electrical resistance on nugget formation during spot welding. Welding Journal, 62, 167s–174s.

Karthikeyan, R., & Balasubramanian, V. (2010). Predict ions of the optimized friction stir spot welding process parameters for joining AA2024 aluminum alloy using RSM. International Journal of Advanced Manufacturing Technology, 51, 173–183.

Kaya, Y., & Kahraman, N. (2012). The effects of electrode force, welding current and welding time on the resistance spot weldability of pure titanium. International Journal of Advanced Manufacturing Technology, 60, 127–134.

Khan, F., Dwivedi, M. D., & Sharma, S. (2012). Development of response surface model for tensile shear strength of weld-bonds of aluminium alloy 6061 T651. Materials & Design, 34, 673–678.

Kim, T., Park, H., & Rhee, S. (2005). Optimization of welding parameters for resistance spot welding of TRIP steel with response surface methodology. International Journal of Production Research, 43, 4643–4657.

Lai, X. M., Luo, A. H., Zhang, Y. S., & Chen, G. L. (2009). Optimal design of electrode cooling system for resistance spot welding with the response surface method. International Journal of Advanced Manufacturing Technology, 41, 226–233.

Lakshiminarayanan, A. K., & Balasubramanian, V. (2009). Comparison of RSM with ANN in predicting tensile strength of friction stir welded AA7039 aluminum alloy joints. Transactions of Nonferrous Metals Society of China, 19, 9–18.

Loghmanian, S. M. R., Yusof, R., Khalid, M., & Ismail, F. S. (2012). Polynomial NARX model structure optimization using multi-objective genetic algorithm. International Journal of Innovative Computing, Information and Control, 8, 7341–7362.

Muhammad, N., Manurung, Y. H. P., Jaafar, R., Abas, S. K., Tham, G., & Haruman, E. (2012). Model development for quality features of resistance spot welding using multi-objective Taguchi method and response surface methodology. Journal of Intelligent Manufacturing. doi:10.1007/s10845-012-0648-3

Muthukumar, M., Mohan, D., & Rajendran, M. (2003). Optimization of mix proportions of mineral aggregates using Box Behnken design of experiments. Cement & Concrete Composites, 25, 751–758.

Olmez, T. (2009). The optimization of Cr (VI) reduction and removal by electrocoagulation using response surface methodology. Journal of Hazardous Materials, 162, 1371–1378.

Raissi, S., & Farsani, R. E. (2009). Statistical process optimization through multi-response surface methodology. World Academy of Science, Engineering and Technology, 51, 267–271.

Rani, M. R., Selamat, H., Zamzuri, H., & Ibrahim, Z. (2012). Multi-objective optimization for PID controller tuning using the global ranking genetic algorithm. International Journal of Innovative Computing, Information and Control, 8, 269–284.

Rowlands, H., & Antony, J. (2003). Application of design of experiments to a spot welding process. Assembly Automation, 23, 273–279.

Saresh, N., Pillai, M. G., & Mathew, J. (2007). Investigations into the effects of electron beam welding on thick Ti-6Al-4V titanium alloy. Journal of Materials Processing Technology, 192–93, 83–88.

Senkara, J., Zhang, H., & Hu, S. J. (2004). Expulsion prediction in resistance spot welding. Welding Journal, 83, 123s–132s.

Siddiquee, A. N., Khan, Z. A., & Mallick, Z. (2010). Grey relational analysis coupled with principal component analysis for optimization design of the process parameters in in-feed centreless cylindrical grinding. International Journal of Advanced Manufacturing Technology, 46, 983–992.

Souza, A. S., Dos Santos, W. N. L., & Ferreira, S. L. C. (2005). Application of Box-Behnken design in the optimization of an on-line pre-concentration system using knotted reactor for cadmium deter-mination by flame atomic absorption spectrometry. Spectrochimica Acta Part B: Atomic Spectroscopy, 60, 737–742.

Sun, X., Stephens, E. V., & Khaleel, M. A. (2008). Effects of fusion zone size and failure mode on peak load and energy absorption of advanced high strength steel spot welds under lap shear loading conditions. Engineering Failure Analysis, 15, 356–367.

Tan, W., Zhou, Y., Kerr, H. W., & Lawson, S. (2004). A study of dynamic resistance during small scale resistance spot welding of thin Ni sheets. Journal of Physics D: Applied Physics, 37, 1998–2008.

Thakur, A. G., & Nandedkar, V. M. (2010). Application of Taguchi method to determine resistance spot welding conditions of austenitic stainless steel AISI 304. Journal of Scientific & Industrial Research, 69, 680–683.

Wen, J., Wang, C. S., Xu, G. C., & Zhang, X. Q. (2009). Real time monitoring weld quality of resistance spot welding for stainless steel. ISIJ International, 49, 553–556.

Xu, J., & Zhai, T. (2008). The small-scale resistance spot welding of refractory alloy 50Mo-50Re thin sheet. JOM Journal of the Minerals, Metals and Materials society, 60, 80–83.

Zhou, Y., Gorman, P., Tan, W., & Ely, K. J. (2000). Weldability of thin sheet metals during small-scale resistance spot welding using an alternating-current power supply. Journal of Electronic Materials, 29, 1090–1099.

Acknowledgments

The authors are grateful for the financial supported by the National Natural Science Foundation of China (11072083) and the Chinese Universities Scientific Fund (C2009M002). The authors are also grateful for the experiment supported by the analysis and test centre of Huazhong University of Science and Technology and Dongfeng Peugeot Citroen Automobile Company Limited.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhao, D., Wang, Y., Sheng, S. et al. Multi-objective optimal design of small scale resistance spot welding process with principal component analysis and response surface methodology. J Intell Manuf 25, 1335–1348 (2014). https://doi.org/10.1007/s10845-013-0733-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10845-013-0733-2