Abstract

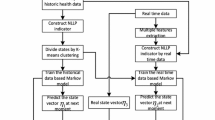

Machine health prognosis plays an important role in the dynamic maintenance decision-making. For complex manufacturing systems, it is necessary to schedule a predictive maintenance program and avoid production losses by predicting machine degradations. This paper proposes a novel prognostic method, a real-time rolling grey forecasting method, to provide efficient and accurate machine health prediction, while effects of influencing factors such as operating load are considered and analyzed. In this grey forecasting model, generating coefficient \(W\) values corresponding to variable operating loads are dynamically generated to overcome the shortage of a static \(W\) value. It improves the forecast accuracy of the frequency of failures. A series data about increasing machine health states of failure frequency is used as the in-sample test data. Results of the out-of-sample predictive data show that the application of the proposed method leads to a noticeable increase in forecast accuracy. This indicates the improved rolling grey forecasting model offers a potential to predict the failure frequency trend for supporting the dynamic maintenance schedule.

Similar content being viewed by others

References

Akay, D., & Atak, M. (2007). Grey prediction with rolling mechanism for electricity demand forecasting of Turkey. Energy, 32(9), 1670–1675.

Alsyouf, I. (2009). Maintenance practices in Swedish industries: Survey results. International Journal of Production Economics, 121(1), 212–223.

Bennane, A., & Yacout, S. (2012). LAD-CBM; new data processing tool for diagnosis and prognosis in condition-based maintenance. Journal of Intelligent Manufacturing, 23(2), 265–275.

Chang, S. C., Lai, H. C., & Yu, H. C. (2005). A variable P value rolling Grey forecasting model for Taiwan semiconductor industry production. Technological Forecasting and Social Change, 72(5), 623–640.

Chien, C. F., Hsu, C. Y., & Hsiao, C. W. (2012a). Manufacturing intelligence to forecast and reduce semiconductor cycle time. Journal of Intelligent Manufacturing, 23(6), 2281–2294.

Chien, C. F., Kim, K. H., Liu, B., & Gen, M. (2012b). Advanced decision and intelligence technologies for manufacturing and logistics. Journal of Intelligent Manufacturing, 23(6), 2133–2135.

Deng, J. L. (1982). Control problems of grey system. Systems and Control Letters, 1(5), 288–294.

He, S. G., He, Z., & Wang, G. A. (2013). Online monitoring and fault identification of mean shifts in bivariate processes using decision tree learning techniques. Journal of Intelligent Manufacturing, 24(1), 25–34.

Hsu, L. C. (2011). Using improved grey forecasting models to forecast the output of opto-electronics industry. Expert Systems with Application, 38(11), 13879–13885.

Jin, X., Li, L., & Ni, J. (2009). Option model for joint production and preventive maintenance system. International Journal of Production Economics, 119(2), 347–353.

Joshi, P., Imadabathuni, M., He, D., Al-Kateb, M., & Bechhoefer, E. (2012). Application of the condition based maintenance checking system for aircrafts. Journal of Intelligent Manufacturing, 23(2), 277–288.

Kung, L. M., & Yu, S. W. (2008). Prediction of index futures returns and the analysis of financial spillovers—A comparison between GARCH and the grey theorem. European Journal of Operational Research, 186(3), 1184–1200.

Lee, J., Ni, J., Djurdjanovic, D., Qiu, H., & Liao, H. (2006). Intelligent prognostics tools and e-maintenance. Computers in Industry, 57(6), 476–489.

Lewis, C. (1982). Industrial and business forecasting methods: A practical guide to exponential smoothing and curve fitting. London: Butterworth Scientific.

Liao, W., Pan, E., & Xi, L. (2010). Preventive maintenance scheduling for repairable system with deterioration. Journal of Intelligent Manufacturing, 21(6), 875–884.

Liao, W., Wang, Y., & Pan, E. (2012). Single-machine-based predictive maintenance model considering intelligent machinery prognostics. International Journal of Advanced Manufacturing Technology, 63(1–4), 51–63.

Lin, H. L. (2012). The use of the Taguchi method with grey relational analysis and a neural network to optimize a novel GMA welding process. Journal of Intelligent Manufacturing, 23(5), 1671–1680.

Lin, T. W., & Wang, C. H. (2012). A hybrid genetic algorithm to minimize the periodic preventive maintenance cost in a series-parallel system. Journal of Intelligent Manufacturing, 23(4), 1225–1236.

Ma, D., Zhang, Q., Peng, Y., & Liu, S. (2011). A Particle Swarm Optimization Based Grey Forecast Model of Underground Pressure for Working Surface. Electronic Journal of Geotechnical Engineering, 16, 811–830.

Mobley, R. K. (2002). An introduction to predictive maintenance. New York: Butterworth-Heinemann, Elsevier Science.

Pham, H., & Wang, H. (1996). Imperfect maintenance. European Journal of Operational Research, 94(3), 425–438.

Rusu, L. I., Rahayu, W., Torabi, T., Puersch, F., Coronado, W., Harris, A. T., et al. (2012). Moving towards a collaborative decision support system for aeronautical data. Journal of Intelligent Manufacturing, 23(6), 2085–2100.

Schutz, J., Rezg, N., & Leger, J. B. (2013). An integrated strategy for efficient business plan and maintenance plan for systems with a dynamic failure distribution. Journal of Intelligent Manufacturing, 24(1), 87–97.

Sheu, D. D., & Kuo, J. Y. (2006). A model for preventive maintenance operations and forecasting. Journal of Intelligent Manufacturing, 17(4), 441–451.

Sun, K., & Li, H. (2010). Scheduling problems with multiple maintenance activities and non-preemptive jobs on two identical parallel machines. International Journal of Production Economics, 124(1), 151–158.

Tian, Z. G. (2012). An artificial neural network method for remaining useful life prediction of equipment subject to condition monitoring. Journal of Intelligent Manufacturing, 23(2), 227–237.

Wang, C. H., & Hsu, L. C. (2008). Using genetic algorithms grey theory to forecast high technology industrial output. Applied Mathematics and Computation, 195(1), 256–263.

Xia, T., Xi, L., Zhou, X., & Du, S. (2012). Modeling and optimizing maintenance schedule for energy systems subject to degradation. Computers and Industrial Engineering, 63(3), 607–614.

Xia, T., Xi, L., Zhou, X., & Lee, J. (2012). Dynamic maintenance decision-making for series-parallel manufacturing system based on MAM-MTW methodology. European Journal of Operational Research, 221(1), 231–240.

Yang, Z., Djurdjanovic, Z., & Ni, J. (2008). Maintenance scheduling in manufacturing systems based on predicted machine degradation. Journal of Intelligent Manufacturing, 19(1), 87–98.

Yu, J., & Xi, L. (2008). Intelligent monitoring and diagnosis of manufacturing process using an integrated approach of neural network ensemble and genetic algorithm. International Journal of Computer Applications in Technology, 33(2–3), 109–119.

Zhang, F., & Jiang, P. (2013). Complexity analysis of distributed measuring and sensing network in multistage machining processes. Journal of Intelligent Manufacturing, 24(1), 55–69.

Zhou, P., Ang, B. W., & Poh, K. L. (2006). Decision analysis in energy and environmental modeling: An update. Energy, 31(14), 2268–2286.

Zhou, X., Xi, L., & Lee, J. (2007). Reliability-centered predictive maintenance scheduling for a continuously monitored system subject to degradation. Reliability Engineering and System Safety, 92(4), 530–534.

Acknowledgments

The authors would like to thank the editor and those anonymous referees for their remarkable comments. The research is funded partially by Programme of Introducing Talents of Discipline to Universities (B06012), Foundation for Innovative Research Groups of the National Natural Science Foundation of China (50821003), National Natural Science Foundation of China (51075277, 51275558) and Program for New Century Excellent Talents in University (NCET-11-0328).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xia, T., Jin, X., Xi, L. et al. Operating load based real-time rolling grey forecasting for machine health prognosis in dynamic maintenance schedule. J Intell Manuf 26, 269–280 (2015). https://doi.org/10.1007/s10845-013-0780-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10845-013-0780-8