Abstract

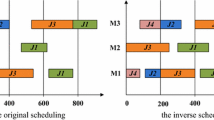

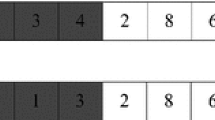

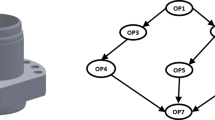

A multi-objective scheduling algorithm with self-evolutionary feature for job-shop-like knowledgeable manufacturing cell (JSKMC) is proposed in this paper, targeting such scheduling issues as make-span, mean complete time of tasks, total tardiness of tasks, number of tardy tasks and the maximum tardiness. Four matrixes are designed to represent the scheduling model of JSKMC. Properties of the key arcs of tasks are discussed and it is found helpless to seek a better solution by reversing the direction of the middle key arcs of tasks. A simplified neighborhood is then established whereby the number of feasible solutions to be searched for is greatly reduced. Based on the above a multi-objective scheduling algorithm with self-evolutionary feature for JSKMC is proposed. Adaptive heuristic critic method is adopted in the algorithm, whose associate search element (ASE) module is designed to select the appropriate action for acquisition of a better solution in the next step by using the knowledge obtained from learning; such an ability of this module can be improved progressively with the increasing training. A scheduling algorithm based on ASE is developed, in which a Pareto archive is embedded to obtain the Pareto optimal solutions. Numerical simulation results confirm the strong ability of the proposed algorithm to home in on the optimal solution by self-evolution via learning.

Similar content being viewed by others

References

Alarcón, R. H., Chueco, J. R., García, J. M. P., & Idoipe, A. V. (2010). Fixture knowledge model development and implementation based on a functional design approach. Robotics and Computer-Integrated Manufacturing, 26(1), 56–66.

Alizon, F., Shooter, S. B., & Simpson, T. W. (2006). Reuse of manufacturing knowledge to facilitate platform-based product realization. Journal of Computing and Information Science in Engineering (Transactions of the ASME), 6(2), 170–178.

Al-Tamimi, A., Abu-Khalaf, M., & Lewis, F. L. (2007). Adaptive critic designs for discrete-time zero-sum games with application to \(\text{ H }_{\infty }\) control. IEEE Transactions on Systems, Man, and Cybernetics-Part B: Cybernetics, 37(1), 240–247.

Aydin, M. E., & Oztemel, E. (2000). Dynamic job-shop scheduling using reinforcement learning agents. Robotics and Autonomous Systems, 33(2), 169–178.

Barto, A. G., Sutton, R. S., & Brouwer, P. S. (1981). Associative search network: A reinforcement learning associative memory. Biological Cybernetics, 40(2), 201–211.

Baykasoglu, A., Ozbakir, L., & Sönmez, A. I. (2004). Using multiple objective tabu search and grammars to model and solve multi-objective flexible job shop scheduling problems. Journal of Intelligent Manufacturing, 15(6), 777–785.

Berkoune, D., & Mesghouni, K. (2008). Resolution approach for multi-objective problems with uncertain demands. European Journal of Operational Research, 187(2), 403–414.

Cao, H. W., & Xue, C. G. (2011). Research on approximation measurement of enterprise information system based on object-based knowledge mesh. Applied Mechanics and Materials, 55, 1857–1862.

Christophe, F., Bernard, A., & Coatanéa, É. (2010). RFBS: A model for knowledge representation of conceptual design. CIRP Annals Manufacturing Technology, 59(1), 155–158.

Chu, M. T., Khosla, R., & Nishida, T. (2012). Communities of practice model driven knowledge management in multinational knowledge based enterprises. Journal of Intelligent Manufacturing, 23(5), 1707–1720.

Chu, M. T., Shyu, J., Tzeng, G. H., & Khosla, R. (2007). Comparison among three analytical methods for knowledge communities group-decision analysis. Expert Systems with Applications, 33(4), 1011–1024.

Deb, A. K., Jayadeva, Gopal, M., et al. (2007). SVM-based tree-type neural networks as a critic in adaptive critic designs for control. IEEE Transactions on Neural Networks, 18(4), 1016–1030.

Garey, M. R., Johnson, D. S., & Sethi, R. (1976). The complexity of flow-shop and job-shop scheduling. Mathematics of Operations Research, 1(2), 117–129.

Gersmann, K., & Hammer, B. (2005). Improving iterative repair strategies for scheduling with the SVM. Neurocomputing, 63(1), 271–292.

Goncalves, J. F., Mendes, J. J. M., & Resende, M. G. C. (2005). A hybrid genetic algorithm for the job shop scheduling problem. European Journal of Operational Research, 167(1), 77–95.

González, M. A., Vela, C. R., González-Rodríguez, et al. (2013). Lateness minimization with tabu search for job shop scheduling problem with sequence dependent setup times. Journal of Intelligent Manufacturing, 24(4), 741–754.

González-Rodríguez, I., Vela, C. R., & Puente, J. (2010). A genetic solution based on lexicographical goal programming for a multiobjective job shop with uncertainty. Journal of Intelligent Manufacturing, 21(1), 65–73.

Herzallah, R. (2013). Probabilistic DHP adaptive critic for nonlinear stochastic control systems. Neural Networks, 42(1), 74–82.

Hiremath, N. C., Sahu, S., & Tiwari, M. K. (2013). Multi objective outbound logistics network design for a manufacturing supply chain. Journal of Intelligent Manufacturing, 24(6), 1071–1084.

Hu, H. S., & Li, Z. W. (2009). Modeling and scheduling for manufacturing grid workflows using timed Petri nets. International Journal of Advanced Manufacturing Technology, 42(5), 553–568.

Kachitvichyanukul, V., & Sitthitham, S. (2011). A two-stage genetic algorithm for multi-objective job shop scheduling problems. Journal of Intelligent Manufacturing, 22(3), 355–365.

Kuah, C. T., Wong, K. Y., & Tiwari, M. K. (2013). Knowledge sharing assessment: An ant colony system based data envelopment analysis approach. Expert Systems with Applications, 40(8), 3137–3144.

Kusiak, A. (2009). Innovation: A data-driven approach. International Journal of Production Economics, 122(1), 440–448.

Kusiak, A., & Smith, M. (2007). Data mining in design of products and production systems. Annual Reviews in Control, 31(1), 147–156.

Lau, J. S. K., Huang, G. Q., Mak, K. L., et al. (2006). Agent-based modeling of supply chains for distributed scheduling. IEEE Transaction on Systems, Man, and Cybernetics-Part A: Systems and Humans, 36(5), 847–861.

Lee, I., & Michael, J. S. (2000). A neural-net approach to real time flow-shop sequencing. Computers & Industrial Engineering, 38(1), 125–147.

Lei, D. M. (2008). A Pareto archive particle swarm optimization for multi-objective job shop scheduling. Computers & Industrial Engineering, 54(4), 960–971.

Li, B. M., Xie, S. Q., & Xu, X. (2011). Recent development of knowledge-based systems, methods and tools for one-of-a-kind production. Knowledge-Based Systems, 24(7), 1108–1119.

Li, J. Q., Pan, Q. K., & Xie, S. X. (2012). An effective shuffled frog-leaping algorithm for multi-objective flexible job shop scheduling problems. Applied Mathematics and Computation, 218(18), 9353–9371.

Liao, C. J., Gen, M., Tiwari, M. K., et al. (2013). Meta-heuristics for manufacturing scheduling and logistics problems. International Journal of Production Economics, 141(1), 440–448.

Loukil, T., Teghem, J., & Fortemps, P. (2007). A multi-objective production scheduling case study solved by simulated annealing. European Journal of Operational Research, 179(3), 709–722.

Lu, H. L., Huang, G. Q., & Yang, H. D. (2011). Integrating order review/release and dispatching rules for assembly job shop scheduling using a simulation approach. International Journal of Production research, 49(3), 647–669.

Lv, Y. L., & Zhang, J. (2011). Performance evaluation of knowledgeable manufacturing systems using Petri nets considering dynamic events. In Proceedings of IEEE international conference on industrial engineering and engineering management (pp. 1821–1825). Singapore: IEEE Press.

Ma, K. P. (2006). A study on self-learning of manufacturing pattern selection in knowledgeable manufacturing. In Proceedings of 6th international conference on intelligent systems design and applications (pp. 1103–1108). Jinan: IEEE Press.

Mati, Y., Dauzère-Pérès, S., & Lahlou, C. (2011). A general approach for optimizing regular criteria in the job-shop scheduling problem. European Journal of Operational research, 212(1), 33–42.

Mattfeld, D. C., & Bierwirth, C. (2004). An efficient genetic algorithm for job shop scheduling with tardiness objectives. European Journal of Operational Research, 155(3), 616–630.

Meeran, S., & Morshed, M. S. (2012). A hybrid genetic tabu search algorithm for solving job shop scheduling problems: A case study. Journal of Intelligent Manufacturing, 23(4), 1063–1078.

Mohagheghi, S., Venayagamoorthy, G. K., & Harley, R. G. (2008). Fully evolvable optimal neurofuzzy controller using adaptive critic designs. IEEE Transactions on Fuzzy Systems, 16(6), 1450–1461.

Morton, T. E., & Pentico, D. W. (1993). Heuristic scheduling systems: With applications to production systems and project management. New York: Wiley.

Moslehi, G., & Mahnam, M. (2011). A Pareto approach to multi-objective flexible job-shop scheduling problem using particle swarm optimization and local search. International Journal of Production Economics, 129(1), 14–22.

Petrovic, D., Duenas, A., & Petrovic, S. (2007). Decision support tool for multi-objective job shop scheduling problems with linguistically quantified decision functions. Decision Support Systems, 43(4), 1527–1538.

Pinedo, M. L. (2008). Scheduling: theory, algorithm, and system (3rd ed.). Berlin: Springer.

Pinedo, M. L., & Singer, M. (1999). A shifting bottleneck heuristic for minimizing the total weighted tardiness in a job shop. Naval Research and Logistics, 46(1), 1–17.

Qing-dao-er-ji, R., Wang, Y. P., & Wang, X. L. (2013). Inventory based two-objective job shop scheduling model and its hybrid genetic algorithm. Applied Soft Computing, 13(3), 1400–1406.

Qiu, X. N., & Lau, H. Y. K. (2013). An AIS-based hybrid algorithm with PDRs for multi-objective dynamic online job shop scheduling problem. Applied Soft Computing, 13(3), 1340–1351.

Sha, D. Y., & Lin, H. H. (2010). A multi-objective PSO for job-shop scheduling problems. Expert Systems with Applications, 37(2), 1065–1070.

Shao, X. Y., Liu, W. Q., Liu, Q., et al. (2013). Hybrid discrete particle swarm optimization for multi-objective flexible job-shop scheduling problem. International Journal of Advanced Manufacturing Technology, 67(9), 2885–2901.

Shervais, S., Shannon, T. T., & Lendaris, G. G. (2003). Intelligent supply chain management using adaptive critic learning. IEEE Transactions on Systems, Man, and Cybernetics-Part A: Systems and Humans, 33(2), 235–244.

Song, Z., & Kusiak, A. (2010). Mining Pareto-optimal modules for delayed product differentiation. European Journal of Operational Research, 201(1), 123–128.

Van, L. P. J. M., Aarts, E. H. L., & Lenstra, J. K. (1992). Job shop scheduling by simulated annealing. Operations Research, 40(1), 113–125.

Wang, L., Zhou, G., Xu, Y., et al. (2012). An enhanced Pareto-based artificial bee colony algorithm for the multi-objective flexible job-shop scheduling. International Journal of Advanced Manufacturing Technology, 60(9), 1111–1123.

Xing, L. N., Chen, Y. W., & Yang, K. W. (2009). An efficient search method for multi-objective flexible job shop scheduling problems. Journal of Intelligent Manufacturing, 20(3), 283–293.

Yan, H. S. (2006). A new complicated knowledge representation approach based on knowledge meshes. IEEE Transactions on Knowledge and Data Engineering, 18(1), 47–62.

Yan, H. S., & Liu, F. (2001). Knowledgeable manufacturing system: A new kind of advanced manufacturing system. Computer Integrated Manufacturing Systems, 7(8), 7–11 (in Chinese).

Yan, H. S., & Ma, K. P. (2011). Competitive diffusion process of repurchased products in knowledgeable manufacturing. European Journal of Operational Research, 208(3), 243–252.

Yan, H. S., & Xue, C. G. (2012). Automatic construction and optimization of knowledge mesh for self-reconfiguration of knowledgeable manufacturing system. Expert Systems with Applications, 39(2), 1799–1810.

Yang, H. B., & Yan, H. S. (2009). An adaptive approach to dynamic scheduling in knowledgeable manufacturing cell. International Journal of Advanced Manufacturing Technology, 42(3–4), 312–320.

Zhang, C. Y., Li, P., Rao, Y., et al. (2008). A very fast TS/SA algorithm for the job-shop scheduling problem. Computers and Operations Research, 35(1), 282–294.

Zhang, R. (2001). Reinforcement learning theory and applications. Harbin: Harbin Engineering University Press (in Chinese).

Zhang, R., Chang, P. C., & Wu, C. (2013). A hybrid genetic algorithm for the job-shop scheduling problem with practical considerations for manufacturing costs: Investigations motivated by vehicle production. International Journal of Production Economics, 145(1), 38–52.

Zhang, R., & Wu, C. (2010). A hybrid immune simulated annealing algorithm for the job shop scheduling problem. Applied Soft Computing, 10(1), 79–89.

Zhou, G. H., Jiang, P. Y., & Huang, G. Q. (2009a). A game-theory approach for job scheduling in networked manufacturing. International Journal of Advanced Manufacturing Technology, 41(9), 972–985.

Zhou, H., Cheung, W., & Leung, L. (2009b). Minimizing weighted tardiness of job-shop scheduling using a hybrid genetic algorithm. European Journal of Operational Research, 194(1), 637–649.

Acknowledgments

This work is supported by a key program of the National Natural Science Foundation of China under Grant 60934008 and the Jiangsu Province University Natural Science Research Project under Grant No. 13KJB460005. The authors thank the Editor-in-Chief & Professor Andrew Kusiak, the Associate Editor, the anonymous reviewers and Professor Li Lu for their valuable comments and suggestions.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yan, HS., Li, WC. A multi-objective scheduling algorithm with self-evolutionary feature for job-shop-like knowledgeable manufacturing cell. J Intell Manuf 28, 337–351 (2017). https://doi.org/10.1007/s10845-014-0981-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10845-014-0981-9