Abstract

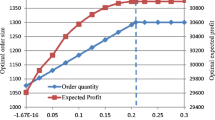

Newsvendor model is one of the most important issues in inventory models. In this paper, we investigate a newsvendor model without lead time, which have difference between distributer and wholesale/retailer. At the end of day, the residual products of newsvendor sold to a secondary market at a unit salvage value. Also, the amount of orders that cannot be met, should be paid the penalty for each unit. In addition, in each one of channels, the percent of these orders cannot be met by the distributer. Then, the newsvendor provides the difference between the amount that ordered to distributor and the amount that met in the occurrence of interruptions risk as a special order from the manufacturer, more expensive than the price of distributor. The limitations of the study are the procurement budget that used for special order. Finally, the model is applied in a real case as a numerical example to determine order amount that maximize profit and is solved by Maple 15. The Kuhn–Tucker method was used to illustrate the optimal points that have necessary condition. Also, the hessian matrix was used to illustrate the optimal points that have sufficient condition for optimization. Consequently, the considered points are global optimum. The main factor in the disruption risk that effect on the ordering amount and profit, are including the probability of appearing of disruption \((p_i)\) and a percent of ordering amount which are met in the case of appearing of disruption \((y_i)\). Therefore, the analysis of sensitivity has been done on two parameters of \(p_i\) and \(y_i\) by using contour curves. According to result of solved problem, the change of disruption appearance reduced. Finally, the proposed method besides being simple is so exact which is sensible in the solved problems.

Similar content being viewed by others

References

Agrawal, N., & Nahmias, S. (1998). Rationalization of the supplier base in the presence of yield uncertainty. Production and Operations Management, 6(3), 291–308.

Andrew, M. R., Ying, R., & Lawrence, V. S. (2008). Supply disruptions with time-dependent parameters. Computers and Operations Research, 35(8), 3504–3529.

Anupindi, R., & Akella, R. (1993). Diversification under supply uncertainty. Management Science, 39(8), 944–963.

Bai, X., & Liu, Y. (2014). Robust optimization of supply chain network design in fuzzy decision system. Journal of Intelligent Manufacturing,. doi:10.1007/s10845-014-0939-y.

Federgruen, A., & Yang, N. (2009). Optimal supply diversification under general supply risks. Operations Research, 57(6), 1451–1468.

Gürler, Ü., & Parlar, M. (1997). An inventory problem with two randomly available suppliers. Operations Research, 45(6), 904–918.

Lavigne, B. B., Bassetto, S., & Agard, B. (2015). A method for a robust optimization of joint product and supply chain design. Journal of Intelligent Manufacturing,. doi:10.1007/s10845-014-0908-5.

Li, X., & Chen, Y. (2010). Impacts of supply disruptions and customer differentiation on a partial-backordering inventory system. Simulation Modelling Practice and Theory, 18(5), 547–557.

Luangpaiboon, P. (2015). Evolutionary elements on composite ascent algorithm for multiple response surface optimization. Journal of Intelligent Manufacturing, 26(3), 539–552.

Mousavi, S. M., Bahreininejad, A., Musa, N. S., & Yusof, F. (2014). A modified particle swarm optimization for solving the integrated location and inventory control problems in a two-echelon supply chain network. Journal of Intelligent Manufacturing. doi:10.1007/s10845-014-0970-z.

Parlar, M. (1997). Continuous-review inventory problem with random supply interruptions. European Journal of Operational Research, 99(2), 366–385.

Ramos, H., & Patricio, M. F. (2014). Some new implicit two-step multiderivative methods for solving special second-order IVP’s. Applied Mathematics and Computation, 239, 227–241.

Ray, P., & Jenamani, M. (2014). Sourcing decision under disruption risk with supply and demand uncertainty: A newsvendor approach. Annals of Operations Research. doi:10.1007/s10479-014-1649-8.

Scavarda, M., Levalle, R. R., Lee, S., & Nof, S. Y. (2015). Collaborative e-work parallelism in supply decisions networks: The chemical dimension. Journal of Intelligent Manufacturing. doi:10.1007/s10845-015-1054-4.

Schmitt, A. J., & Snyder, L. V. (2012). Infinite-horizon models for inventory control under yield uncertainty and disruptions. Computers & Operations Research, 39(4), 850–862.

Silbermayr, L., & Minner, S. (2013). A multiple sourcing inventory model under disruption risk. International Journal of Production Economics, 149, 37–46.

Stanislavova. M. & Stefanov. A. (2013). Spectral stability analysis for special solutions of second order in time PDEs: The higher dimensional case. Physica D: Nonlinear Phenomena, pp. 1–13.

Tomlin, B., & Wang, Y. (2005). On the value of mix flexibility and dual sourcing in unreliable newsvendor networks. Manufacturing & Service Operations Management, 7(1), 37–57.

Veeraraghavan, S., & Scheller, W. A. (2008). Now or later: A simple policy for effective dual sourcing in capacitated systems. Operations Research, 56(4), 850–864.

Wu, C. H., & Chuang, Y. T. (2011). An efficient algorithm for stochastic capacity portfolio planning problems. Journal of Intelligent Manufacturing, 23(6), 2161–2170.

Xanthopoulos, A., Vlachos, D., & Iakovou, E. (2012). Optimal newsvendor policies for dual-sourcing supply chains: A disruption risk management framework. Computers & Operations Research, 39(2), 350–357.

Xiang, W., Song, F., & Ye, F. (2014). Order allocation for multiple supply-demand networks within a cluster. Journal of Intelligent Manufacturing, 25(6), 1367–1376.

Xiao, T., & Qi, X. (2008). Price competition, cost and demand disruptions and coordination of a supply chain with one manufacturer and two competing retailers. Omega, 36(5), 741–753.

Yahia, W. B., Ayadi, O., & Masmoudi, F. (2015). A fuzzy-based negotiation approach for collaborative planning in manufacturing supply chains. Journal of Intelligent Manufacturing. doi:10.1007/s10845-015-1085-x.

Yang, G., & Liu, Y. (2015). Designing fuzzy supply chain network problem by mean-risk optimization method. Journal of Intelligent Manufacturing, 26(3), 447–458.

Yan, X., & Liu, K. (2009). An inventory system with two suppliers and default risk. Operations Research Letters, 37(5), 322–326.

Zanotti, O., & Dumbser, M. (2014). A high order special relativistic hydrodynamic and magneto hydrodynamic code with space–time adaptive mesh refinement. Computer Physics Communications, 188, 110–127.

Zhang, D. Y., Cao, X., Wang, L., & Zeng, Y. (2011). Mitigating the risk of information leakage in a two-level supply chain through optimal supplier selection. Journal of Intelligent Manufacturing, 23(4), 1351–1354.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ledari, A.M., Pasandideh, S.H.R. & Koupaei, M.N. A new newsvendor policy model for dual-sourcing supply chains by considering disruption risk and special order. J Intell Manuf 29, 237–244 (2018). https://doi.org/10.1007/s10845-015-1104-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10845-015-1104-y