Abstract

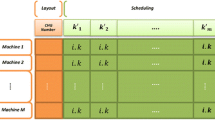

Concurrent design of cell formation and scheduling is an effective method for better implementing cellular manufacturing. To address the integrated cell formation and scheduling problem, a nonlinear mixed integer programming mathematical model is developed in this paper. This newly proposed model features the simultaneous consideration of many design attributes, such as duplicate machines, alternative process routings, reentrant parts and variable cell number. Several linearization techniques are proposed to transform it into a mixed integer linear programming formulation. An improved genetic algorithm (IGA) is developed to solve large-scale problems efficiently. To remove redundancy between two chromosomes, a cell renumbering procedure is applied in IGA. An illustrative example problem is solved and the results show that the integration of cell formation and scheduling can remarkably reduce the flowtime of cellular manufacturing systems. A set of thirteen test problems with various scale is used to further evaluate the performance of IGA. Comparison of the results obtained by IGA with those obtained by Lingo and CPLEX reveals the better effectiveness and efficiency of IGA.

Similar content being viewed by others

References

Ah kioon, S., Bulgak, A. A., & Bektas, T. (2009). Integrated cellular manufacturing systems design with production planning and dynamic system reconfiguration. European Journal of Operational Research, 192(2), 414–428.

Arkat, J., Farahani, M. H., & Ahmadizar, F. (2012). Multi-objective genetic algorithm for cell formation problem considering cellular layout and operations scheduling. International Journal of Computer Integrated Manufacturing, 25(7), 625–635.

Costa, A., Cappadonna, F. A., & Fichera, S. (2015). A hybrid genetic algorithm for minimizing makespan in a flow-shop sequence-dependent group scheduling problem. Journal of Intelligent Manufacturing. doi:10.1007/s10845-015-1049-1.

Defersha, F. M., & Chen, M. (2006). A comprehensive mathematical model for the design of cellular manufacturing systems. International Journal of Production Economics, 103(2), 767–783.

Defersha, F. M., & Chen, M. (2008). A linear programming embedded genetic algorithm for an integrated cell formation and lot sizing considering product quality. European Journal of Operational Research, 187(1), 46–69.

Elmi, A., Solimanpur, M., Topaloglu, S., & Elmi, A. (2011). A simulated annealing algorithm for the job shop cell scheduling problem with intercellular moves and reentrant parts. Computers and Industrial Engineering, 61(1), 171–178.

França, P. M., Gupta, J. N. D., Mendes, A. S., Moscato, P., & Veltink, K. J. (2005). Evolutionary algorithms for scheduling a flowshop manufacturing cell with sequence dependent family setups. Computers and Industrial Engineering, 48(3), 491–506.

Ghosh, T., Sengupta, S., Chattopadhyay, M., & Dan, P. K. (2011). Meta-heuristics in cellular manufacturing: A state-of-the-art review. International Journal of Industrial Engineering Computations, 2(1), 87–122.

Halat, K., & Bashirzadeh, R. (2015). Concurrent scheduling of manufacturing cells considering sequence-dependent family setup times and intercellular transportation times. International Journal of Advanced Manufacturing Technology, 77(9–12), 1907–1915.

Ilić, O. R. (2014). An e-Learning tool considering similarity measures for manufacturing cell formation. Journal of Intelligent Manufacturing, 25(3), 617–628.

Kao, Y., & Chen, C. C. (2014). Automatic clustering for generalised cell formation using a hybrid particle swarm optimisation. International Journal of Production Research, 52(12), 3466–3484.

Kia, R., Baboli, A., Javadian, N., Tavakkoli-Moghaddam, R., Kazemi, M., & Khorrami, J. (2012). Solving a group layout design model of a dynamic cellular manufacturing system with alternative process routings, lot splitting and flexible reconfiguration by simulated annealing. Computers and Operations Research, 39(11), 2642–2658.

Li, X., Baki, M. F., & Aneja, Y. P. (2010). An ant colony optimization metaheuristic for machine-part cell formation problems. Computers & Operations Research, 37(12), 2071–2081.

Pandian, R. S., & Mahapatra, S. S. (2009). Manufacturing cell formation with production data using neural networks. Computers and Industrial Engineering, 56(4), 1340–1347.

Sarac, T., & Ozcelik, F. (2012). A genetic algorithm with proper parameters for manufacturing cell formation problems. Journal of Intelligent Manufacturing, 23(4), 1047–1061.

Saxena, L. K., & Jain, P. K. (2011). Dynamic cellular manufacturing systems design—A comprehensive model. International Journal of Advanced Manufacturing Technology, 53(1–4), 11–34.

Solimanpur, M., Vrat, P., & Shankar, R. (2004). A heuristic to minimize makespan of cell scheduling problem. International Journal of Production Economics, 88(3), 231–241.

Tang, J., Wang, X., Kaku, I., & Yung, K. L. (2010). Optimization of parts scheduling in multiple cells considering intercell move using scatter search approach. Journal of Intelligent Manufacturing, 21(4), 525–537.

Tang, J., Yan, C., Wang, X., & Zeng, C. (2014). Using lagrangian relaxation decomposition with heuristic to integrate the decisions of cell formation and parts scheduling considering intercell moves. IEEE Transactions on Automation Science and Engineering, 11(4), 1110–1121.

Tavakkoli-Moghaddam, R., Jafari-Zarandini, Y., & Gholipour-Kanani, Y. (2010). Multi-objective particle swarm optimization for sequencing and scheduling a cellular manufacturing system. In D. S. Huang, M. McGinnity, L. Heutte, & X. P. Zhang (Eds.), Advanced intelligent computing theories and applications. Communications in Computer and Information Science (Vol. 93, pp. 69–75). Changsha: Springer, Berlin Heidelberg.

Tavakkoli-Moghaddam, R., Ranjbar-Bourani, M., Amin, G. R., & Siadat, A. (2012). A cell formation problem considering machine utilization and alternative process routes by scatter search. Journal of Intelligent Manufacturing, 23(4), 1127–1139.

Venkataramanaiah, S. (2008). Scheduling in cellular manufacturing systems: An heuristic approach. International Journal of Production Research, 46(2), 429–449.

Wang, X., Tang, J., & Yung, K. L. (2010). A scatter search approach with dispatching rules for a joint decision of cell formation and parts scheduling in batches. International Journal of Production Research, 48(12), 3513–3534.

Wemmerlov, U., & Hyer, N. L. (1989). Cellular manufacturing in the US industry: A survey of users. International Journal of Production Research, 27(9), 1511–1530.

Wu, X., Chu, C. H., Wang, Y., & Yue, D. (2007). Genetic algorithms for integrating cell formation with machine layout and scheduling. Computers and Industrial Engineering, 53(2), 277–289.

Xambre, A. R., & Vilarinho, P. M. (2003). A simulated annealing approach for manufacturing cell formation with multiple identical machines. European Journal of Operational Research, 151(2), 434–446.

Yin, Y., & Yasuda, K. (2006). Similarity coefficient methods applied to the. cell formation problem: A taxonomy and review. International Journal of Production Economics, 101(2), 329–352.

Zhang, C. Y., Rao, Y. Q., & Li, P. G. (2008). An effective hybrid genetic algorithm for the job shop scheduling problem. International Journal of Advanced Manufacturing Technology, 39(9–10), 965–974.

Acknowledgments

The authors would like to thank anonymous referees for their remarkable comments and this research is supported by National Natural Science Foundation of China (51475304, 51505288).

Author information

Authors and Affiliations

Corresponding author

Appendix: Proof of two Propositions

Appendix: Proof of two Propositions

Proposition 1

The absolute term in Constraint (7) can be linearized by the transformation \(\left| \sum \limits _{m\in \mathbf{M}_{k+1,p} } \sum \limits _{j\in \mathbf{MS}_m } {X_{k+1,pmjc} } -\sum \limits _{m\in \mathbf{M}_{kp}} \sum \limits _{j\in \mathbf{MS}_m } {X_{kpmjc}} \right| = \alpha _{kpc}^+ +\alpha _{kpc}^-\), under the following set of constraints:

Proof

Let \(\beta _{k+1,p} =\sum \limits _{c\in \mathbf{C}} \sum \limits _{m\in \mathbf{M}_{k+1,p}} \sum \limits _{j\in \mathbf{MS}_m } {T_{k+1,pm} \cdot X_{k\hbox {+}1,pmjc}}\). According to (9), the following formula can be obtained.

Based on (7) and Proposition 1, substituting \(t_{p,k,k+1} =\frac{TE_p }{2}\cdot \sum \limits _{c\in \mathbf{C}} {\left( {\alpha _{kpc}^+ +\alpha _{kpc}^- } \right) }\) into the formula (25),

Consider three different cases:

-

(i)

\(\sum \limits _{m\in \mathbf{M}_{k+1,p} } {\sum \limits _{j\in \mathbf{MS}_m } {X_{k+1,pmjc} } } >\sum \limits _{m\in \mathbf{M}_{kp} } {\sum \limits _{j\in \mathbf{MS}_m } {X_{kpmjc} } } \). According to (13), \(\alpha _{kpc}^+ -\alpha _{kpc}^- >0\). Since this is a minimization problem, \(\alpha _{kpc}^- =0\) and \(\alpha _{kpc}^+ =\sum \limits _{m\in \mathbf{M}_{k+1,p}} {\sum \limits _{j\in \mathbf{MS}_m } {X_{k+1,pmjc} } } -\sum \limits _{m\in \mathbf{M}_{kp} } {\sum \limits _{j\in \mathbf{MS}_m } {X_{kpmjc} } } \) will make the right side of the formula (26) be minimum so that the optimal solution can be hold.

-

(ii)

\(\sum \limits _{m\in \mathbf{M}_{k+1,p} } {\sum \limits _{j\in \mathbf{MS}_m } {X_{k+1,pmjc} } } <\sum \limits _{m\in \mathbf{M}_{kp} } {\sum \limits _{j\in \mathbf{MS}_m } {X_{kpmjc} } } \). According to (13), \(\alpha _{kpc}^+ -\alpha _{kpc}^- <0\). \(\alpha _{kpc}^+ =0\) and \(\alpha _{kpc}^- =\sum \limits _{m\in \mathbf{M}_{kp} } {\sum \limits _{j\in \mathbf{MS}_m } {X_{kpmjc} } } -\sum \limits _{m\in \mathbf{M}_{k+1,p} } {\sum \limits _{j\in \mathbf{MS}_m } {X_{k+1,pmjc} } } \) will make the right side of the formula (26) be minimum so that the optimal solution can be hold.

-

(iii)

\(\sum \limits _{m\in \mathbf{M}_{k+1,p} } {\sum \limits _{j\in \mathbf{MS}_m } {X_{k+1,pmjc} } } =\sum \limits _{m\in \mathbf{M}_{kp} } {\sum \limits _{j\in \mathbf{MS}_m} {X_{kpmjc}}}\). According to (13), \(\alpha _{kpc}^+ -\alpha _{kpc}^- =0\). \(\alpha _{kpc}^+ =0\) and \(\alpha _{kpc}^- =0\) will make the right side of the formula (26) be minimum so that the optimal solution can be hold. \(\square \)

Proposition 2

Constraint (10) can be replaced by the following constraints so that it can be linearized.

Proof

Since an operation of a certain part cannot be processed in two cells, for every \(c_1 ,c_2 \in \mathbf{C}\left( {c_1 \ne c_2 } \right) \), \(X_{kpmjc_1 } \cdot X_{kpmjc_2}\) cannot be equal to 1. Consider two different cases:

-

(i)

\(\sum \limits _{c\in \mathbf{C}} {\left( {X_{kpmjc} \cdot X_{k^{\prime }p^{\prime }mjc} } \right) } =0\), which can be resulted from one of the following three sub-cases.

-

(a)

\(\exists c_1 ,X_{kpmjc_1 } =1\) and \(X_{k^{\prime }p^{\prime }mjc_1 } =0\).

It means the jth copy of machine type m is assigned to cell \(c_{1} (Y_{mjc_1 } =1)\) and kth operation of part p is processed in cell \(c_{1}\). Since a machine cannot be assigned to more than one cell,

$$\begin{aligned} Y_{mjc} =0\quad \forall c\in \mathbf{C}\backslash \left\{ {c_1 } \right\} \end{aligned}$$Based on Constraint (4),

$$\begin{aligned} X_{k^{\prime }p^{\prime }mjc} = 0\quad \forall c\in \mathbf{C}\backslash \left\{ {c_1 } \right\} \end{aligned}$$Since an operation of a certain part cannot be processed in two cells,

$$\begin{aligned} X_{kpmjc} = 0\quad \forall c\in \mathbf{C}\backslash \left\{ {c_1 } \right\} \end{aligned}$$Therefore,

$$\begin{aligned} \sum _{c\in \mathbf{C}} {X_{k^{\prime }p^{\prime }mjc} }= & {} \sum _{c\in \mathbf{C}\backslash \left\{ {c_1 } \right\} } {X_{k^{\prime }p^{\prime }mjc} } +X_{k^{\prime }p^{\prime }mjc_1 } =0\\ \sum _{c\in \mathbf{C}} {X_{kpmjc} }= & {} \sum _{c\in \mathbf{C}\backslash \left\{ {c_1 } \right\} } {X_{kpmjc} } +X_{kpmjc_1 } =1 \end{aligned}$$Under Constraint (29), \(Z_{kpk^{\prime }p^{\prime }mj} =0\) and \(Z_{k^{\prime }p^{\prime }kpmj} =0\).

-

(b)

\(\exists c_1 ,X_{k^{\prime }p^{\prime }mjc_1 } =1\) and \(X_{kpmjc_1 } =0\), which is similar to the last sub-case.

-

(c)

\(X_{kpmjc} =0\) and \(X_{k^{\prime }p^{\prime }mjc} =0\) for every \(c\in \mathbf{C}\). Under Constraints (29), \(Z_{kpk^{\prime }p^{\prime }mj} =0\) and \(Z_{k^{\prime }p^{\prime }kpmj} =0\).

To sum up, when \(\sum \limits _{c\in \mathbf{C}} {\left( {X_{kpmjc} \cdot X_{k^{\prime }p^{\prime }mjc} } \right) } =0\),

$$\begin{aligned} Z_{kpk^{\prime }p^{\prime }mj} +Z_{k^{\prime }p^{\prime }kpmj} =\sum _{c\in \mathbf{C}} {\left( {X_{kpmjc} \cdot X_{k^{\prime }p^{\prime }mjc} } \right) } =0 \end{aligned}$$ -

(a)

-

(ii)

\(\sum \limits _{c\in \mathbf{C}} {\left( {X_{kpmjc} \cdot X_{k^{\prime }p^{\prime }mjc} } \right) } =1\).

Such a situation arises only when \(\exists c_1 ,X_{kpmjc_1 } =1\) and \(X_{k^{\prime }p^{\prime }mjc_1 } =1\). Since an operation of a certain part cannot be processed in two cells,

$$\begin{aligned} \sum _{c\in \mathbf{C}} {X_{k^{\prime }p^{\prime }mjc} }= & {} \sum _{c\in \mathbf{C}\backslash \left\{ {c_1 } \right\} } {X_{k^{\prime }p^{\prime }mjc} } +X_{k^{\prime }p^{\prime }mjc_1 } =0+1=0 \\ \sum _{c\in \mathbf{C}} {X_{kpmjc} }= & {} \sum _{c\in \mathbf{C}\backslash \left\{ {c_1 } \right\} } {X_{kpmjc} } +X_{kpmjc_1 } =0+1=1 \end{aligned}$$$$\begin{aligned} Z_{kpk^{\prime }p^{\prime }mj} +Z_{k^{\prime }p^{\prime }kpmj} =1 \end{aligned}$$Therefore, when \(\sum \limits _{c\in \mathbf{C}} {\left( {X_{kpmjc} \cdot X_{k^{\prime }p^{\prime }mjc} } \right) } =1\),

$$\begin{aligned} Z_{kpk^{\prime }p^{\prime }mj} +Z_{k^{\prime }p^{\prime }kpmj} =\sum _{c\in \mathbf{C}} {\left( {X_{kpmjc} \cdot X_{k^{\prime }p^{\prime }mjc} } \right) } =1 \end{aligned}$$

Rights and permissions

About this article

Cite this article

Feng, H., Xia, T., Da, W. et al. Concurrent design of cell formation and scheduling with consideration of duplicate machines and alternative process routings. J Intell Manuf 30, 275–289 (2019). https://doi.org/10.1007/s10845-016-1245-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10845-016-1245-7