Abstract

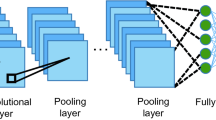

By applying a deep neural network to selective laser melting, we studied a classification model of melt-pool images with respect to 6 laser power labels. Laser power influenced to form pores or cracks determining the part quality and was positively-linearly dependent to the density of the part. Using the neural network of which the number of nodes is dropped with increasing the layer number achieved satisfactory inference when melt-pool images had blurred edges. The proposed neural network showed the classification failure rate under 1.1% for 13,200 test images and was more effective to monitor melt-pool images because it simultaneously handled various shapes, comparing with a simple calculation such as the sum of pixel intensity in melt-pool images. The classification model could be utilized to infer the location to cause the unexpected alteration of microstructures or separate the defective products non-destructively.

Similar content being viewed by others

Explore related subjects

Discover the latest articles and news from researchers in related subjects, suggested using machine learning.References

Abhishek, K., Kumar, V. R., Datta, S., & Mahapatra, S. S. (2017). Parametric appraisal and optimization in machining of CFRP composites by using TLBO (Teaching Learning Based Optimization algorithm). Journal of Intelligent Manufacturing,28(8), 1769–1785.

Aminzadeh, M., & Kurfess, T. R. (2018). Online quality inspection using Bayesian classification in powder-bed additive manufacturing from high-resolution visual camera images. Journal of Intelligent Manufacturing. https://doi.org/10.1007/s10845-018-1412-0.

Bauereiß, A., Scharowsky, T., & Körner, C. (2014). Defect generation and propagation mechanism during additive manufacturing by selective beam melting. Journal of Materials Processing Technology,214(11), 2522–2528.

Bengio, Y., Simard, P., & Frasconi, P. (1994). Learning long-term dependencies with gradient descent is difficult. IEEE Transactions on Neural Networks,5(2), 157–166.

Berumen, S., Bechmann, F., Lindner, S., Kruth, J.-P., & Craeghs, T. (2010). Quality control of laser- and powder bed-based Additive Manufacturing (AM) technologies. Physics Procedia,5(13), 617–622.

Cho, J.-H., Kim, M.-S., & Ji, S.-Y. (2017). Apparatus for recording location of forming in 3D printer and 3D printer having the same. KR Patent 10-1793573, 3 Nov 2017.

Conrady, S., & Jouffe, L. (2015). Bayesian networks and bayesialab—A practical introduction for researchers. Franklin: Bayesia USA.

Craeghs, T., Clijsters, S., Kruth, J.-P., Bechmann, F., & Ebert, M.-C. (2012). Detection of process failures in layerwise laser melting with optical process monitoring. Physics Procedia,39, 753–759.

Cristianini, N., & Shawe-Taylor, J. (2000). An introduction to support vector machines: And other kernel-based learning methods. New York: Cambridge University Press.

D’Addona, D. M., Ullah, A. M. M. S., & Matarazzo, D. (2017). Tool-wear prediction and pattern-recognition using artificial neural network and DNA-based computing. Journal of Intelligent Manufacturing,28(6), 1285–1301.

DeCost, B. L., Jain, H., Rollett, A. D., & Holm, E. A. (2017). Computer vision and machine learning for autonomous characterization of AM powder feedstocks. JOM Journal of the Minerals Metals and Materials Society,69(3), 456–465.

Everton, S. K., Hirsch, M., Stavroulakis, P., Leach, R. K., & Clare, A. T. (2016). Review of in situ process monitoring and in situ metrology for metal additive manufacturing. Materials and Design,95(5), 431–445.

Garg, A., Lam, J. S. L., & Savalani, M. M. (2018). Laser power based surface characteristics models for 3-D printing process. Journal of Intelligent Manufacturing,29(6), 1191–1202.

Goodfellow, I., Bengio, Y., & Courville, A. (2016). Deep learning. Cambridge: The MIT Press.

Haykin, S. (1998). Neural networks: A comprehensive foundation. Upper Saddle River: Prentice Hall.

Hinton, G., Osindero, S., & Teh, Y. (2006). A fast learning algorithm for deep belief nets. Neural Computation,18(7), 1527–1554.

Ioffe, S., & Szegedy, C. (2015). Batch normalization: Accelerating deep network training by reducing internal covariate shift. CoRR, http://arxiv.org/abs/1502.03167.

Jackson, P. (1998). Introduction to expert systems. Boston: Addison-Wesley Pub. Co.

Khairallah, S. A., Anderson, A. T., Rubenchik, A., & King, W. E. (2016). Laser powder-bed fusion additive manufacturing: Physics of complex melt flow and formation mechanisms of pores, spatter, and denudation zones. Acta Materialia,108, 36–45.

Krizhevsky, A., Sutskever, I., & Hinton, G. E. (2012). ImageNet classification with deep convolutional neural networks. In NIPS’12 proceedings of the 25th international conference on neural information processing systems (Vol. 1, pp. 1097–1105).

Lane, B., Moylan, S., Whitenton, E., & Ma, L. (2016). Thermographic measurements of the commercial laser powder bed fusion process at NIST. Rapid Prototyping Journal,22(5), 778–787.

Li, S. Z. (1994). Markov random field models in computer vision. European Conference on Computer Vision,1994, 361–370.

Librantz, A. F. H., de Araujo, S. A., Alves, W. A. L., Belan, P. A., Mesquita, R. A., & Selvatici, A. H. P. (2017). Artificial intelligence based system to improve the inspection of plastic mould surfaces. Journal of Intelligent Manufacturing,28(1), 181–190.

Mohamed, O. A., Masood, S. H., & Bhowmik, J. L. (2017). Influence of processing parameters on creep and recovery behavior of FDM manufactured part using definitive screening design and ANN. Rapid Prototyping Journal,23(6), 998–1010.

Panda, B., Shankhwar, K., Garg, A., & Savalani, M. M. (2016). Evaluation of genetic programming-based models for simulating bead dimensions in wire and arc additive manufacturing. Journal of Intelligent Manufacturing. https://doi.org/10.1007/s10845-016-1282-2.

Pashazadeh, H., Gheisari, Y., & Hamedi, M. (2016). Statistical modeling and optimization of resistance spot welding process parameters using neural networks and multi-objective genetic algorithm. Journal of Intelligent Manufacturing,27(3), 549–559.

Ren, S., He, K., Girshick, R., & Sun, J. (2017). Faster R-CNN: Towards real-time object detection with region proposal networks. IEEE Transactions on Pattern Analysis and Machine Intelligence,39(6), 1137–1149.

Rokach, L., & Maimon, O. Z. (2014). Data mining with decision trees: Theory and applications. River Edge: World Scientific Publishing Co.

Seifi, M., Salem, A., Beuth, J., Harrysson, O., & Lewandowski, J. J. (2016). Overview of materials qualification needs for metal additive manufacturing. JOM Journal of the Minerals Metals and Materials Society,68(3), 747–764.

Shi, Q., Gu, D., Xia, M., Cao, S., & Rong, T. (2016). Effects of laser processing parameters on thermal behavior and melting/solidification mechanism during selective laser melting of TiC/Inconel 718 composites. Optics & Laser Technology,84, 9–22.

Song, L., Huang, W., Han, X., & Mazumder, J. (2017). Doubly fed induction generator system resonance active damping through stator virtual impedance. IEEE Transactions on Industrial Electronics,64(1), 633–642.

Sun, T.-H., Tien, F.-C., Tien, F.-C., & Kuo, R.-J. (2016). Automated thermal fuse inspection using machine vision and artificial neural networks. Journal of Intelligent Manufacturing,27(3), 639–651.

Sun, Y., Wang, X., & Tang, X. (2013). Deep convolutional network cascade for facial point detection. In Proceedings of the 2013 IEEE conference on computer vision and pattern recognition (pp. 3476–3483).

Tapia, G., & Elwany, A. (2014). A review on process monitoring and control in metal-based additive manufacturing. Journal of Manufacturing Science and Engineering,136(6), 060801.

Tsai, K.-M., & Luo, H.-J. (2017). An inverse model for injection molding of optical lens using artificial neural network coupled with genetic algorithm. Journal of Intelligent Manufacturing,28(2), 473–487.

Xiong, J., Zhang, G., Hu, J., & Wu, L. (2014). Bead geometry prediction for robotic GMAW-based rapid manufacturing through a neural network and a second-order regression analysis. Journal of Intelligent Manufacturing,25(1), 157–163.

YLR-AC 400W Datasheet. (2018). IPG Photonics, http://www.ipgphotonics.com. Accessed 12 Apr 2018.

You, D., Gao, X., & Katayama, S. (2015). WPD-PCA-based laser welding process monitoring and defects diagnosis by using FNN and SVM. IEEE Transactions on Industrial Electronics,62(1), 628–636.

Zeiler, M. D. (2012). ADADELTA: An adaptive learning rate method. CoRR, http://arxiv.org/abs/1212.5701.

Zhang, W., Yang, G., Lin, Y., Gupta, M. M., & Ji, C. (2018). On definition of deep learning. In Paper presented at the World Automation Congress 2018, 3–6 June 2018. Skamania Lodge, Stevenson, Washington.

Zhang, Y., Bernard, A., Harik, R., & Karunakaran, K. P. (2017). Build orientation optimization for multi-part production in additive manufacturing. Journal of Intelligent Manufacturing,28(6), 1393–1407.

Zhao, Y., Sun, J., Gupta, M. M., Moody, W., Laverty, W. H., & Zhang, W. (2017). Developing a mapping from affective words to design parameters for affective design of apparel products. Textile Research Journal,87(18), 2224–2232.

Acknowledgement

This work was supported by the Korea Institute of Industrial Technology as “Development of high efficient production technology for high purity titanium powder and additive manufacturing processing technology (KITECH EO-18-0012)”.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kwon, O., Kim, H.G., Ham, M.J. et al. A deep neural network for classification of melt-pool images in metal additive manufacturing. J Intell Manuf 31, 375–386 (2020). https://doi.org/10.1007/s10845-018-1451-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10845-018-1451-6