Abstract

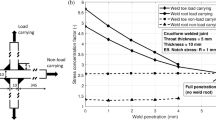

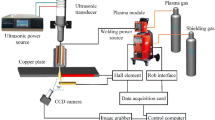

The monitoring and control of weld penetration in pulsed gas metal arc welding (GMAW-P) is considerably challenging, especially in field applications. The metal transfer and pulse current in GMAW-P complicate the identification of weld penetration. In previous studies, the authors found that both the change in arc voltage during the peak current period and the average arc voltage during the peak current period can be used for condition monitoring of weld pool surface and thus for the estimation of GMAW-P penetration depth. In the present work, the relative fluctuation coefficient (CRF) of weld pool surface is proposed by combining these two signals to predict the weld penetration depth. Model predictive control using this coefficient as feedback is employed to control the penetration depth. The experimental results show that uniform weld penetration depth can be obtained by the adaptive control algorithm. The practice attempted in this work can be expected to be a candidate solution for GMAW-P penetration control, which is easy to implement in field applications.

Similar content being viewed by others

References

Carlson, N. M., & Johnson, J. A. (1988). Ultrasonic sensing of weld pool penetration. Welding Journal,67(11), 239s–246s.

Chen, Z. Y., Chen, J., & Feng, Z. L. (2017). Monitoring weld pool surface and penetration using reversed electrode images. Welding Journal,96(10), 367s–375s.

Chen, J. S., Chen, J., Zhang, K., Feng, Z., & Zhang, Y. M. (2018). Dynamic reflection behaviors of weld pool surface in pulsed GTAW. Welding Journal,97(6), 191s–206s.

Cheng, Y. C., Xiao, J., Chen, S. J., & Zhang, Y. M. (2018). Intelligent penetration welding of thin-plate GTAW process based on arc voltage feedback. Transactions of the China Welding Institution,39(12), 1–4.

Chokkalingham, S., Chandrasekhar, N., & Vasudevan, M. (2012). Predicting weld bead width and depth of penetration from infrared thermal image of weld pool using artificial neural network. Journal of Intelligent Manufacturing,23(5), 1995–2001.

Fan, C. J., Lv, F. L., & Chen, S. B. (2009). Visual sensing and penetration control in aluminum alloy pulsed GTA welding. International Journal of Advanced Manufacturing Technology,42(1–2), 126–137.

Hu, J., Guo, H., & Tsai, H. L. (2008). Weld pool dynamics and the formation of ripples in 3D gas metal arc welding. International Journal of Heat and Mass Transfer,51(9–10), 2537–2552.

Li, C. K., Shi, Y., Gu, Y., & Yuan, P. (2018). Monitoring weld pool oscillation using reflected laser pattern in gas tungsten arc welding. Journal of Materials Processing Technology,255, 876–885.

Liang, Z. M., Chang, H. X., Wang, Q. Y., Wang, D. L., & Zhang, Y. M. (2019). 3D reconstruction of weld pool surface in pulsed GMAW by passive biprism stereo vision. IEEE Robotics and Automation Letters,4(3), 3091–3097.

Liu, Y. K., & Zhang, Y. M. (2014). Model-based predictive control of weld penetration in gas tungsten arc welding. IEEE Transactions on Control Systems Technology,22(3), 955–966.

Ma, X. J., & Zhang, Y. M. (2009). Reflection of illumination laser from gas metal arc weld pool surface. Measurement Science & Technology,20(11), 115105.

Ma, X. J., & Zhang, Y. M. (2011). Gas metal arc weld pool surface imaging: modeling and processing. Welding Journal,90(5), 85s–94s.

Mnich, C., Al-Bayat, F., Debrunner, C., Steele, J., & Vincent, T. (2004). In situ weld pool measurement using stereovision. In Proceedings of 2004 Japan–USA symposium on flexible automation (pp. 1–2), ASME.

Modi, S., Lin, Y. Z., Cheng, L., Yang, G. S., Liu, L. Z., & Zhang, W. J. (2011). A socially inspired framework for human state inference using expert opinion integration. IEEE/ASME Transactions on Mechatronics,16(5), 874–878.

Rao, Z. H., Zhou, J., Liao, S. M., & Tsai, H. L. (2010). Three-dimensional modeling of transport phenomena and their effect on the formation of ripples in gas metal arc welding. Journal of Applied Physics,107(5), 054905.

Renwick, R. J., & Richardson, R. W. (1983). Experimental investigation of GTA weld pool oscillations. Welding Journal,62(2), 29s–35s.

Rokhlin, S. I., & Guu, A. C. (1990). Computerized radiographic sensing and control of an arc welding process. Welding Journal,69(3), 83s–95s.

Shi, Y., Li, C. K., Du, L. M., Gu, Y. F., & Zhu, M. (2016). Frequency characteristics of weld pool oscillation in pulsed gas tungsten arc welding. Journal of Manufacturing Processes,24, 145–151.

Song, H. S., & Zhang, Y. M. (2008). Measurement and analysis of three-dimensional specular gas tungsten arc weld pool surface. Welding Journal,87(4), 85s–95s.

Wang, Z. Z. (2014). Monitoring of GMAW weld pool from the reflected laser lines for real-time control. IEEE Transactions on Industrial Informatics,10(4), 2073–2083.

Wang, Z. Z. (2015). An imaging and measurement system for robust reconstruction of weld pool during arc welding. IEEE Transactions on Industrial Electronics,62(8), 5109–5118.

Wang, Z. Z. (2017). Unsupervised recognition and characterization of the reflected laser lines for robotic gas metal arc welding. IEEE Transactions on Industrial Informatics,13(4), 1866–1876.

Wang, J. F., Wang, W. Y., & Chen, S. B. (2009). Inspection of welding pool height from shading in pulsed GTAW with wire filler. Industrial Robot,36(3), 270–276.

Wang, W. D., Wang, Z. J., Hu, S. S., Bai, P., Lu, T., & Cao, Y. (2018). Weld pool surface fluctuations sensing in pulsed GMAW. Welding Journal,97(12), 327s–337s.

Wang, Q. L., Yang, C. L., & Geng, Z. (1993). Separately excited resonance phenomenon of the weld pool and its application. Welding Journal,72(9), 455s–462s.

Wang, Z. J., Zhang, Y. M., & Wu, L. (2010). Measurement and estimation of weld pool surface depth and weld penetration in pulsed gas metal arc welding. Welding Journal,89(6), 117s–126s.

Xiao, Y. H., & Den Ouden, G. (1993). Weld pool oscillation during GTA welding of mild steel. Welding Journal,72(8), 428s–434s.

Yoo, C. D., & Richardson, R. W. (1993). An experimental study on sensitivity and signal characteristics of welds pool oscillation. Transactions of the Japan Welding Society,24(2), 54–62.

Zhang, W. J., Wang, X. W., & Zhang, Y. M. (2013a). Analytical real-time measurement of a three-dimensional weld pool surface. Measurement Science & Technology,24(11), 115011.

Zhang, G. J., Yan, Z. H., & Wu, L. (2006). Reconstructing a three-dimensional P-GMAW weld pool shape from a two-dimensional visual image. Measurement Science & Technology,17(7), 1877–1882.

Zhang, K., Zhang, Y. M., Chen, J. S., & Wu, S. J. (2017). Observation and analysis of three-dimensional weld pool oscillation dynamic behaviors. Welding Journal,96(5), 143s–153s.

Zhang, W. J., Zhang, X., & Zhang, Y. M. (2013b). Robust pattern recognition for measurement of three dimensional weld pool surface in GTAW. Journal of Intelligent Manufacturing,26(4), 659–676.

Zhao, D. B., Yi, J. Q., Chen, S. B., Wu, L., & Chen, Q. (2003). Extraction of three-dimensional parameters for weld pool surface in pulsed GTAW with wire filler. Journal of Manufacturing Science and Engineering-Transactions of the ASME,125(3), 493–503.

Acknowledgements

This study is supported by National Natural Science Foundation of China (Grant No. 51505326), Natural Science Foundation of Tianjin (Grant No. 16JCQNJC04300) and the Regional Demonstration Project of Marine Economic Innovation and Development (Grant No. BHSF2017-10).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zou, S., Wang, Z., Hu, S. et al. Control of weld penetration depth using relative fluctuation coefficient as feedback. J Intell Manuf 31, 1203–1213 (2020). https://doi.org/10.1007/s10845-019-01506-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10845-019-01506-8