Abstract

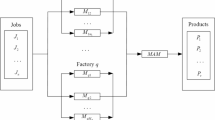

The classical distributed production scheduling problem (DPSP) assumes that factories are identical, and each factory is composed of just some machines. Inspired by the fact that manufacturers these days typically work across different factories, and each of these factories normally has some workshops, we study an important extension of the DPSP with different factories and workshops (DPFW), where jobs can be processed and transferred between the factories, workshops and machines. To the best of our knowledge, this is the very first time distributed production scheduling with different factories and workshops is studied. We propose a novel memetic algorithm (MA) to solve this DPFW, aiming to minimize the makespan and total energy consumption. The proposed MA is incorporated with a well-designed chromosome encoding method and a balance-transfer initialization method to generate a good initial population. An effective local search operator is also presented to improve the MA’s convergence speed and fully exploit its solution space. A total of 50 DPFW benchmark instances are used to evaluate the performance of our MA. Computational experiments carried out confirm that the MA is able to easily obtain better solutions for the majority of the tested problem instances compared to three other well-known algorithms, demonstrating its superior performance over these algorithms in terms of solution quality. Our proposed method and the results presented here may be helpful for production managers who work with distributed manufacturing systems in scheduling their production activities by considering different factories and workshops. With this DPFW, imbalanced resource loads and unexpected bottlenecks, which regularly arise in traditional DPSP models, can be easily avoided.

Similar content being viewed by others

References

Awasthi, A., & Omrani, H. (2019). A goal-oriented approach based on fuzzy axiomatic design for sustainable mobility project selection. International Journal of Systems Science: Operations & Logistics,6(1), 86–98.

Blum, C., Chiong, R., Clerc, M., De Jong, K., Michalewicz, Z., Neri, F., et al. (2012). Evolutionary optimization. In T. Weise, Z. Michalewicz, & R. Chiong (Eds.), Variants of evolutionary algorithms for real-world applications (pp. 1–29). Berlin: Springer. ISBN 978-3-642-23423-1.

Chan, F. T. S., Chung, S. H., & Chan, P. L. Y. (2005). An adaptive genetic algorithm with dominated genes for distributed scheduling problems. Expert Systems with Applications,29(2), 364–371.

Chang, H.-C., & Liu, T.-K. (2017). Optimisation of distributed manufacturing flexible job shop scheduling by using hybrid genetic algorithms. Journal of Intelligent Manufacturing,28(8), 1973–1986.

Chaouch, I., Driss, O. B., & Ghedira, K. (2017). A survey of optimization techniques for distributed job shop scheduling problems in multi-factories. Advances in Intelligent Systems and Computing,1, 369–378.

Chaouch, I., Driss, O. B., & Ghedira, K. (2019). A novel dynamic assignment rule for the distributed job shop scheduling problem using a hybrid ant-based algorithm. Applied Intelligence,49(5), 1903–1924.

Cheng, R., Gen, M., & Tsujimura, Y. (1996). A tutorial survey of job-shop scheduling problems using genetic algorithms-representation. Computers & Industrial Engineering,30(4), 983–997.

Dauzère-Pérès, S., & Paulli, J. (1997). An integrated approach for modeling and solving the general multiprocessor job-shop scheduling problem using tabu search. Annals of Operations Research,70(1), 281–306.

De Giovanni, L., & Pezzella, F. (2010). An improved genetic algorithm for the distributed and flexible job-shop scheduling problem. European Journal of Operational Research,200(2), 395–408.

Deb, K., & Jain, H. (2014). An evolutionary many-objective optimization algorithm using reference-point-based nondominated sorting approach, part I: Solving problems with box constraints. IEEE Transactions on Evolutionary Computation,18(4), 577–601.

Deb, K., Pratap, A., Agarwal, S., & Meyarivan, T. (2002). A fast and elitist multiobjective genetic algorithm: NSGA-II. IEEE Transactions on Evolutionary Computation,6(2), 182–197.

Duan, C., Deng, C., Gharaei, A., Wu, J., & Wang, B. (2018). Selective maintenance scheduling under stochastic maintenance quality with multiple maintenance actions. International Journal of Production Research,56(23), 7160–7178.

Dubey, R., Gunasekaran, A., Sushil, & Singh, T. (2015). Building theory of sustainable manufacturing using total interpretive structural modelling. International Journal of Systems Science: Operations & Logistics,2(4), 231–247.

Gao, K. Z., Suganthan, P. N., Pan, Q. K., Tasgetiren, M. F., & Sadollah, A. (2016). Artificial bee colony algorithm for scheduling and rescheduling fuzzy flexible job shop problem with new job insertion. Knowledge-Based Systems,109, 1–16.

Gharaei, A., Hoseini Shekarabi, S. A., & Karimi, M. (2019a). Modelling and optimal lot-sizing of the replenishments in constrained, multi-product and bi-objective EPQ models with defective products: Generalised cross decomposition. International Journal of Systems Science: Operations & Logistics. https://doi.org/10.1080/23302674.2019.1574364.

Gharaei, A., Hoseini Shekarabi, S. A., Karimi, M., Pourjavad, E., & Amjadian, A. (2019b). An integrated stochastic EPQ model under quality and green policies: Generalised cross decomposition under the separability approach. International Journal of Systems Science: Operations & Logistics. https://doi.org/10.1080/23302674.2019.1656296.

Gharaei, A., Karimi, M., & Hoseini Shekarabi, S. A. (2019c). Joint economic lot-sizing in multi-product multi-level integrated supply chains: Generalized benders decomposition. International Journal of Systems Science: Operations & Logistics. https://doi.org/10.1080/23302674.2019.1585595.

Gharaei, A., Karimi, M., & Shekarabi, S. A. H. (2019d). An integrated multi-product, multi-buyer supply chain under penalty, green, and quality control polices and a vendor managed inventory with consignment stock agreement: The outer approximation with equality relaxation and augmented penalty algorithm. Applied Mathematical Modelling,69, 223–254.

Giri, B., & Bardhan, S. (2014). Coordinating a supply chain with backup supplier through buyback contract under supply disruption and uncertain demand. International Journal of Systems Science: Operations & Logistics,1(4), 193–204.

Giri, B., & Masanta, M. (2018). Developing a closed-loop supply chain model with price and quality dependent demand and learning in production in a stochastic environment. International Journal of Systems Science: Operations & Logistics. https://doi.org/10.1080/23302674.2018.1542042.

Giri, B. C., Roy, B., & Maiti, T. (2017). Coordinating a three-echelon supply chain under price and quality dependent demand with sub-supply chain and RFM strategies. Applied Mathematical Modelling,52, 747–769.

Gong, G., Chiong, R., Deng, Q., Han, W., Zhang, L., Lin, W., et al. (2020). Energy-efficient flexible flow shop scheduling with worker flexibility. Expert Systems with Applications,141, 112902.

Gong, G., Deng, Q., Chiong, R., Gong, X., & Huang, H. (2019). An effective memetic algorithm for multi-objective job-shop scheduling. Knowledge-Based Systems,182, 104840.

Gong, M., Jiao, L., Du, H., & Bo, L. (2009). Multiobjective immune algorithm with nondominated neighbor-based selection. Evolutionary Computation,16(2), 225–255.

Hao, Y., Helo, P., & Shamsuzzoha, A. (2018). Virtual factory system design and implementation: Integrated sustainable manufacturing. International Journal of Systems Science: Operations & Logistics,5(2), 116–132.

Hoseini Shekarabi, S. A., Gharaei, A., & Karimi, M. (2019). Modelling and optimal lot-sizing of integrated multi-level multi-wholesaler supply chains under the shortage and limited warehouse space: Generalised outer approximation. International Journal of Systems Science: Operations & Logistics,6(3), 237–257.

Hsu, C. Y., Kao, B. R., Ho, V. L., & Lai, K. R. (2016). Agent-based fuzzy constraint-directed negotiation mechanism for distributed job shop scheduling. Engineering Applications of Artificial Intelligence,53, 140–154.

Hurink, J., Jurisch, B., & Thole, M. (1994). Tabu search for the job-shop scheduling problem with multi-purpose machines. Operations-Research-Spektrum,15(4), 205–215.

Jia, H. Z., Fuh, J. Y. H., Nee, A. Y. C., & Zhang, Y. F. (2007). Integration of genetic algorithm and Gantt chart for job shop scheduling in distributed manufacturing systems. Computers & Industrial Engineering,53(2), 313–320.

Kacem, I., Hammadi, S., & Borne, P. (2014). Pareto-optimality approach for flexible job-shop scheduling problems: Hybridization of evolutionary algorithms and fuzzy logic. Mathematics & Computers in Simulation,60(3), 245–276.

Kazemi, N., Abdul-Rashid, S. H., Ghazilla, R. A. R., Shekarian, E., & Zanoni, S. (2018). Economic order quantity models for items with imperfect quality and emission considerations. International Journal of Systems Science: Operations & Logistics,5(2), 99–115.

Li, J.-Q., Duan, P., Cao, J., Lin, X.-P., & Han, Y.-Y. (2018). A hybrid Pareto-based tabu search for the distributed flexible job shop scheduling problem with E/T criteria. IEEE Access,6, 58883–58897.

Lin, J., Wang, Z.-J., & Li, X. (2017). A backtracking search hyper-heuristic for the distributed assembly flow-shop scheduling problem. Swarm and Evolutionary Computation,36, 124–135.

Liu, T.-K., Chen, Y.-P., & Chou, J.-H. (2014). Solving distributed and flexible job-shop scheduling problems for a real-world fastener manufacturer. IEEE Access,2, 1598–1606.

Lu, P.-H., Wu, M.-C., Tan, H., Peng, Y.-H., & Chen, C.-F. (2018). A genetic algorithm embedded with a concise chromosome representation for distributed and flexible job-shop scheduling problems. Journal of Intelligent Manufacturing,29(1), 19–34.

Montgomery, D. C. (2008). Design & analysis of experiments. Hoboken: Wiley.

Naderi, B., & Azab, A. (2014). Modeling and heuristics for scheduling of distributed job shops. Expert Systems with Applications,41(17), 7754–7763.

Naderi, B., & Azab, A. (2015). An improved model and novel simulated annealing for distributed job shop problems. The International Journal of Advanced Manufacturing Technology,81(1–4), 693–703.

Naderi, B., & Ruiz, R. (2010). The distributed permutation flowshop scheduling problem. Computers & Operations Research,37(4), 754–768.

Naderi, B., & Ruiz, R. (2014). A scatter search algorithm for the distributed permutation flowshop scheduling problem. European Journal of Operational Research,239(2), 323–334.

Nobil, A. H., Sedigh, A. H. A., & Cárdenas-Barrón, L. E. (2016). A multi-machine multi-product EPQ problem for an imperfect manufacturing system considering utilization and allocation decisions. Expert Systems with Applications,56, 310–319.

Nobil, A. H., Sedigh, A. H. A., & Cárdenas-Barrón, L. E. (2017a). A multiproduct single machine economic production quantity (EPQ) inventory model with discrete delivery order, joint production policy and budget constraints. Annals of Operations Research, 9, 1–37.

Nobil, A. H., Sedighb, A. H. A., & Cárdenas-Barrónc, L. E. (2017b). Multi-machine economic production quantity for items with scrapped and rework with shortages and allocation decisions 2. Scientia Iranica: Transaction E, Industrial Engineering, 25(4), 2331–2346.

Pasandideh, S. H. R., Niaki, S. T. A., Nobil, A. H., & Cárdenas-Barrón, L. E. (2015). A multiproduct single machine economic production quantity model for an imperfect production system under warehouse construction cost. International Journal of Production Economics,169, 203–214.

Phan, D. A., Vo, T. L. H., & Lai, A. N. (2019). Supply chain coordination under trade credit and retailer effort. International Journal of Production Research,57(9), 2642–2655.

Rabbani, M., Foroozesh, N., Mousavi, S. M., & Farrokhi-Asl, H. (2019). Sustainable supplier selection by a new decision model based on interval-valued fuzzy sets and possibilistic statistical reference point systems under uncertainty. International Journal of Systems Science: Operations & Logistics,6(2), 162–178.

Rabbani, M., Hosseini-Mokhallesun, S. A. A., Ordibazar, A. H., & Farrokhi-Asl, H. (2018). A hybrid robust possibilistic approach for a sustainable supply chain location-allocation network design. International Journal of Systems Science: Operations & Logistics. https://doi.org/10.1080/23302674.2018.1506061.

Rifai, A. P., Nguyen, H.-T., & Dawal, S. Z. M. (2016). Multi-objective adaptive large neighborhood search for distributed reentrant permutation flow shop scheduling. Applied Soft Computing,40, 42–57.

Sarkar, S., & Giri, B. (2018). Stochastic supply chain model with imperfect production and controllable defective rate. International Journal of Systems Science: Operations & Logistics. https://doi.org/10.1080/23302674.2018.1536231.

Sayyadi, R., & Awasthi, A. (2018a). An integrated approach based on system dynamics and ANP for evaluating sustainable transportation policies. International Journal of Systems Science: Operations & Logistics. https://doi.org/10.1080/23302674.2018.1554168.

Sayyadi, R., & Awasthi, A. (2018b). A simulation-based optimisation approach for identifying key determinants for sustainable transportation planning. International Journal of Systems Science: Operations & Logistics,5(2), 161–174.

Shah, N. H., Chaudhari, U., & Cárdenas-Barrón, L. E. (2018). Integrating credit and replenishment policies for deteriorating items under quadratic demand in a three echelon supply chain. International Journal of Systems Science: Operations & Logistics. https://doi.org/10.1080/23302674.2018.1487606.

Shao, W., Pi, D., & Shao, Z. (2017). Optimization of makespan for the distributed no-wait flow shop scheduling problem with iterated greedy algorithms. Knowledge-Based Systems,137, 163–181.

Shao, W., Pi, D., & Shao, Z. (2019). A Pareto-based estimation of distribution algorithm for solving multiobjective distributed no-wait flow-shop scheduling problem with sequence-dependent setup time. IEEE Transactions on Automation Science and Engineering, 16(3), 1344–1360.

Storer, R., Wu, S., & Vaccari, R. (1992). New search spaces for sequencing instances with application to job shop. Management Science,38, 1495–1509.

Tsao, Y.-C. (2015). Design of a carbon-efficient supply-chain network under trade credits. International Journal of Systems Science: Operations & Logistics,2(3), 177–186.

Wang, S.-Y., & Wang, L. (2016). An estimation of distribution algorithm-based memetic algorithm for the distributed assembly permutation flow-shop scheduling problem. IEEE Transactions on Systems, Man, and Cybernetics: Systems,46(1), 139–149.

Wang, S.-Y., Wang, L., Liu, M., & Xu, Y. (2013). An effective estimation of distribution algorithm for solving the distributed permutation flow-shop scheduling problem. International Journal of Production Economics,145(1), 387–396.

Wisittipanich, W., & Kachitvichyanukul, V. (2013). An efficient PSO algorithm for finding pareto-frontier in multi-objective job shop scheduling problems. Industrial Engineering & Management Systems,12(2), 151–160.

Wu, X., Liu, X., & Zhao, N. (2019). An improved differential evolution algorithm for solving a distributed assembly flexible job shop scheduling problem. Memetic Computing, 11(4), 1–21.

Xu, Y., Wang, L., Wang, S., & Liu, M. (2014). An effective hybrid immune algorithm for solving the distributed permutation flow-shop scheduling problem. Engineering Optimization,46(9), 1269–1283.

Yin, S., Nishi, T., & Zhang, G. (2016). A game theoretic model for coordination of single manufacturer and multiple suppliers with quality variations under uncertain demands. International Journal of Systems Science: Operations & Logistics,3(2), 79–91.

Yuan, Y., & Xu, H. (2015). Multiobjective flexible job shop scheduling using memetic algorithms. IEEE Transactions on Automation Science and Engineering,12(1), 336–353.

Zhang, R., & Chiong, R. (2016). Solving the energy-efficient job shop scheduling problem: A multi-objective genetic algorithm with enhanced local search for minimizing the total weighted tardiness and total energy consumption. Journal of Cleaner Production,112, 3361–3375.

Ziaee, M. (2014). A heuristic algorithm for the distributed and flexible job-shop scheduling problem. The Journal of Supercomputing,67(1), 69–83.

Acknowledgements

This work was supported by the National Key R&D Program of China (Grant No. 2018YFB1701400); the National Natural Science Foundation of China (Grant No. 71473077); the State Key Laboratory of Advanced Design and Manufacturing for Vehicle Body, Hunan University (Grant No. 71775004); and the State Key Laboratory of Construction Machinery (Grant No. SKLCM2019-03).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Gong, G., Chiong, R., Deng, Q. et al. A memetic algorithm for multi-objective distributed production scheduling: minimizing the makespan and total energy consumption. J Intell Manuf 31, 1443–1466 (2020). https://doi.org/10.1007/s10845-019-01521-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10845-019-01521-9