Abstract

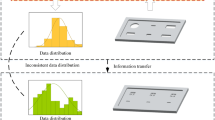

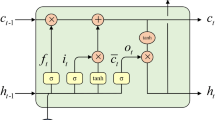

In order to capture temporal interactions among processes in manufacturing and assembly processes, an end-to-end unified product quality prediction framework called QTD is proposed in this paper. It consists of three modules: quality embedding model pool, temporal-interactive model, and decoding model. Besides, to handle the information transfer and integration problems in the time direction of parallel processes, a novel bidirectional serial–parallel LSTM (Bi-SP-LSTM) is devised as an instantiated model of temporal-interactive model. Bi-SP-LSTM is an extension of bidirectional long short-term memory. Moreover, an unsupervised task and a loss function named adversarial focal loss have been designed to give the framework the ability to assess heteroscedastic uncertainty in classification task due to intrinsic uncertainty in data. Furthermore, experiments are devised based on a subset of a public dataset from Kaggle competition to demonstrate the validity of the proposed framework. Compared with other latest methods, the proposed framework is verified to be more accurate and robust. Taking Matthews correlation coefficient as an example, the adversarial Bi-SP-LSTM-based QTD framework is superior to the best existing methods with 95% confidence interval in most cases, and its mean MCC is 4.88% higher than the best existing method. The results suggest that the proposed framework has a broad application prospect for quality prediction in manufacturing and assembly processes.

Similar content being viewed by others

References

Akbik, A., Blythe, D., & Vollgraf, R. (2018). Contextual string embeddings for sequence labeling. In Proceedings of the 27th international conference on computational linguistics (pp. 1638–1649).

Asiltürk, I., & Çunkaş, M. (2011). Modeling and prediction of surface roughness in turning operations using artificial neural network and multiple regression method. Expert Systems with Applications,38(5), 5826–5832. https://doi.org/10.1016/j.eswa.2010.11.041.

Charte, F., Rivera, A. J., del Jesus, M. J., & Herrera, F. (2015). Addressing imbalance in multilabel classification: Measures and random resampling algorithms. Neurocomputing,163, 3–16. https://doi.org/10.1016/j.neucom.2014.08.091.

Colledani, M., Tolio, T., Fischer, A., Iung, B., Lanza, G., Schmitt, R., et al. (2014). Design and management of manufacturing systems for production quality. CIRP Annals,63(2), 773–796. https://doi.org/10.1016/j.cirp.2014.05.002.

D’Agostino, R. B. (1971). An omnibus test of normality for moderate and large size samples. Biometrika,58(2), 341–348. https://doi.org/10.1093/biomet/58.2.341.

Dehkordi, B., Moallem, M., & Parsapour, A. (2011). Predicting foaming slag quality in electric arc furnace using power quality indices and fuzzy method. IEEE Transactions on Instrumentation and Measurement,60(12), 3845–3852. https://doi.org/10.1109/TIM.2010.2085190.

Ding, M., Zhou, C., Chen, Q., Yang, H., & Tang, J. (2019). Cognitive graph for multi-hop reading comprehension at scale. arXiv preprint arXiv:1905.05460. https://doi.org/10.18653/v1/p19-1259.

Dyer, C., Ballesteros, M., Ling, W., Matthews, A., & Smith, N. A. (2015). Transition-based dependency parsing with stack long short-term memory. In Proceedings of the 53rd annual meeting of the association for computational linguistics and the 7th international joint conference on natural language processing (Vol. 1, pp. 334–343). https://doi.org/10.3115/v1/p15-1033.

García-Escudero, L. A., Duque-Perez, O., Fernandez-Temprano, M., & Morinigo-Sotelo, D. (2017). Robust detection of incipient faults in VSI-fed induction motors using quality control charts. IEEE Transactions on Industry Applications,53(3), 3076–3085. https://doi.org/10.1109/TIA.2016.2617300.

Grzenda, M., & Bustillo, A. (2019). Semi-supervised roughness prediction with partly unlabeled vibration data streams. Journal of Intelligent Manufacturing,30(2), 933–945. https://doi.org/10.1007/s10845-018-1413-z.

Hanin, B. (2017). Universal function approximation by deep neural nets with bounded width and ReLu activations. arXiv preprint arXiv:1708.02691. https://doi.org/10.3390/math7100992.

Hao, L., Bian, L., Gebraeel, N., & Shi, J. (2017). Residual life prediction of multistage manufacturing processes with interaction between tool wear and product quality degradation. IEEE Transactions on Automation Science and Engineering,14(2), 1211–1224. https://doi.org/10.1109/TASE.2015.2513208.

Hebert, J. (2016). Predicting rare failure events using classification trees on large scale manufacturing data with complex interactions. In 2016 IEEE international conference on Big Data (Big Data) (pp. 2024–2028). IEEE. https://doi.org/10.1109/bigdata.2016.7840825.

Hochreiter, S., & Schmidhuber, J. (1997). Long short-term memory. Neural Computation,9(8), 1735–1780. https://doi.org/10.1162/neco.1997.9.8.1735.

Hu, J., Zhou, M., Li, X., & Xu, Z. (2017). Online model regression for nonlinear time-varying manufacturing systems. Automatica,78, 163–173. https://doi.org/10.1016/j.automatica.2016.12.012.

Huang, Q., & Shi, J. (2004). Stream of variation modeling and analysis of serial–parallel multistage manufacturing systems. Journal of Manufacturing Science Engineering,126(3), 611–618. https://doi.org/10.1115/1.1765149.

Jiang, P., Jia, F., Wang, Y., & Zheng, M. (2014). Real-time quality monitoring and predicting model based on error propagation networks for multistage machining processes. Journal of Intelligent Manufacturing,25(3), 521–538. https://doi.org/10.1007/s10845-012-0703-0.

Jiao, J., Zhang, L., & Pokharel, S. (2007). Process platform planning for variety coordination from design to production in mass customization manufacturing. IEEE Transactions on Engineering Management,54(1), 112–129. https://doi.org/10.1109/TEM.2006.889071.

Karayel, D. (2009). Prediction and control of surface roughness in CNC lathe using artificial neural network. Journal of Materials Processing Technology,209(7), 3125–3137. https://doi.org/10.1016/j.jmatprotec.2008.07.023.

Kendall, A., & Gal, Y. (2017). What uncertainties do we need in Bayesian deep learning for computer vision? In Advances in neural information processing systems (pp. 5574–5584).

Kingma, D. P., & Ba, J. (2014). Adam: A method for stochastic optimization. arXiv preprint arXiv:1412.6980.

Kirchen, I., Vogel-Heuser, B., Hildenbrand, P., Schulte, R., Vogel, M., Lechner, M., et al. (2017). Data-driven model development for quality prediction in forming technology. In 2017 IEEE 15th international conference on industrial informatics (INDIN) (pp. 775–780). IEEE. https://doi.org/10.1109/indin.2017.8104871.

Li, J. (2004). Modeling and analysis of manufacturing systems with parallel lines. IEEE Transactions on Automatic Control,49(10), 1824–1832. https://doi.org/10.1109/TAC.2004.835584.

Lin, T.-Y., Goyal, P., Girshick, R., He, K., & Dollár, P. (2017). Focal loss for dense object detection. In Proceedings of the IEEE international conference on computer vision (pp. 2980–2988). https://doi.org/10.1109/iccv.2017.324.

Liu, G., Gao, X., You, D., & Zhang, N. (2019). Prediction of high power laser welding status based on PCA and SVM classification of multiple sensors. Journal of Intelligent Manufacturing,30(2), 821–832. https://doi.org/10.1007/s10845-016-1286-y.

Lusa, A. (2008). A survey of the literature on the multiple or parallel assembly line balancing problem. European Journal of Industrial Engineering,2(1), 50–72. https://doi.org/10.1504/EJIE.2008.016329.

Mangal, A., & Kumar, N. (2016). Using big data to enhance the Bosch production line performance: A Kaggle challenge. In 2016 IEEE international conference on Big Data (Big Data) (pp. 2029–2035). IEEE. https://doi.org/10.1109/bigdata.2016.7840826.

Pavlyshenko, B. (2016). Machine learning, linear and bayesian models for logistic regression in failure detection problems. In 2016 IEEE international conference on Big Data (Big Data), 2016 (pp. 2046–2050). IEEE. https://doi.org/10.1109/bigdata.2016.7840828.

Pearson, E. S., D’Agostino, R. B., & Bowman, K. O. (1977). Tests for departure from normality: Comparison of powers. Biometrika,64(2), 231–246. https://doi.org/10.1093/biomet/64.2.231.

Peters, M. E., Neumann, M., Iyyer, M., Gardner, M., Clark, C., Lee, K., et al. (2018). Deep contextualized word representations. In Proceedings of the 2018 conference of the North American chapter of the association for computational linguistics: Human language technologies (Vol. 1, pp. 2227–2237). https://doi.org/10.18653/v1/n18-1202.

Rotondo, A., Young, P., & Geraghty, J. (2013). Quality risk prediction at a non-sampling station machine in a multi-product, multi-stage, parallel processing manufacturing system subjected to sequence disorder and multiple stream effects. Annals of Operations Research,209(1), 255–277. https://doi.org/10.1007/s10479-012-1145-y.

Schuster, M., & Paliwal, K. K. (1997). Bidirectional recurrent neural networks. IEEE Transactions on Signal Processing,45(11), 2673–2681. https://doi.org/10.1109/78.650093.

Smirnov, N. (1948). Table for estimating the goodness of fit of empirical distributions. The Annals of Mathematical Statistics,19(2), 279–281. https://doi.org/10.1214/aoms/1177730256.

Stump, B., & Badurdeen, F. (2012). Integrating lean and other strategies for mass customization manufacturing: A case study. Journal of Intelligent Manufacturing,23(1), 109–124. https://doi.org/10.1007/s10845-009-0289-3.

Su, Q., Liu, L., & Whitney, D. E. (2010). A systematic study of the prediction model for operator-induced assembly defects based on assembly complexity factors. IEEE Transactions on Systems, Man, and Cybernetics, Part A: Systems Humans,40(1), 107–120. https://doi.org/10.1109/TSMCA.2009.2033030.

Tai, K. S., Socher, R., & Manning, C. D. (2015). Improved semantic representations from tree-structured long short-term memory networks. In Proceedings of the 53rd annual meeting of the association for computational linguistics and the 7th international joint conference on natural language processing (Vol. 1, pp. 1556–1566). https://doi.org/10.3115/v1/p15-1150.

Tangjitsitcharoen, S., Thesniyom, P., & Ratanakuakangwan, S. (2017). Prediction of surface roughness in ball-end milling process by utilizing dynamic cutting force ratio. Journal of Intelligent Manufacturing,28(1), 13–21. https://doi.org/10.1007/s10845-014-0958-8.

Vaswani, A., Shazeer, N., Parmar, N., Uszkoreit, J., Jones, L., Gomez, A. N., et al. (2017). Attention is all you need. In Advances in neural information processing systems (pp. 5998–6008).

Wang, C., Chen, K., Wang, C., & Chang, P. (2011). Application of 6-sigma design system to developing an improvement model for multi-process multi-characteristic product quality. Proceedings of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture,225(7), 1205–1216. https://doi.org/10.1177/2041297510393464.

Wang, G., & Jiao, J. (2017). A kernel least squares based approach for nonlinear quality-related fault detection. IEEE Transactions on Industrial Electronics,64(4), 3195–3204. https://doi.org/10.1109/TIE.2016.2637886.

Wang, Y., Huang, M., & Zhao, L. (2016). Attention-based LSTM for aspect-level sentiment classification. In Proceedings of the 2016 conference on empirical methods in natural language processing (pp. 606–615). https://doi.org/10.18653/v1/d16-1058.

Weiss, S. M., Dhurandhar, A., Baseman, R. J., White, B. F., Logan, R., Winslow, J. K., et al. (2016). Continuous prediction of manufacturing performance throughout the production lifecycle. Journal of Intelligent Manufacturing,27(4), 751–763. https://doi.org/10.1007/s10845-014-0911-x.

Welch, B. L. (1947). The generalization of student’s’ problem when several different population variances are involved. Biometrika,34(1/2), 28–35. https://doi.org/10.2307/2332510.

Wu, F., Duan, X., Xiao, J., Zhao, Z., Tang, S., Zhang, Y., et al. (2017). Temporal interaction and causal influence in community-based question answering. IEEE Transactions on Knowledge Data Engineering,29(10), 2304–2317. https://doi.org/10.1109/TKDE.2017.2720737.

Xu, P., Mei, H., Ren, L., & Chen, W. (2017). ViDX: Visual diagnostics of assembly line performance in smart factories. IEEE Transactions on Visualization Computer Graphics,23(1), 291–300. https://doi.org/10.1109/TVCG.2016.2598664.

Yang, T., Tsai, T.-N., & Yeh, J. (2005). A neural network-based prediction model for fine pitch stencil-printing quality in surface mount assembly. Engineering Applications of Artificial Intelligence,18(3), 335–341. https://doi.org/10.1016/j.engappai.2004.09.004.

Yin, S., Liu, L., & Hou, J. (2016). A multivariate statistical combination forecasting method for product quality evaluation. Information Sciences,355, 229–236. https://doi.org/10.1016/j.ins.2016.03.035.

Zar, J. H. (1999). Biostatistical analysis. New Delhi: Pearson Education India.

Zhang, D., Xu, B., & Wood, J. (2016). Predict failures in production lines: A two-stage approach with clustering and supervised learning. In 2016 IEEE international conference on Big Data (Big Data) (pp. 2070–2074). IEEE. https://doi.org/10.1109/bigdata.2016.7840832.

Zhang, Y., & Yang, J. (2018). Chinese NER using lattice LSTM. In Proceedings of the 56th annual meeting of the association for computational linguistics (Vol. 1, pp. 1554–1564). https://doi.org/10.18653/v1/p18-1144.

Zhao, L., Diao, G., & Yao, Y. (2016a). A dynamic process adjustment method based on residual prediction for quality improvement. IEEE Transactions on Industrial Informatics,12(1), 41–50. https://doi.org/10.1109/TII.2015.2494885.

Zhao, L., Dou, R., Yin, J., & Yao, Y. (2016b). Intelligent prediction method of quality for continuous casting process. In 2016 IEEE advanced information management, communicates, electronic and automation control conference (IMCEC) (pp. 1761–1764). IEEE https://doi.org/10.1109/imcec.2016.7867521.

Acknowledgements

This work is supported by National Natural Science Foundation of China (51805473, 51935009), Postdoctoral Research Fund of Zhejiang Province of China (zj20180101), and Discovery Grant Program of National Sciences and Engineering Research Council of Canada (RGPIN-2018-05471).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Liu, Z., Zhang, D., Jia, W. et al. An adversarial bidirectional serial–parallel LSTM-based QTD framework for product quality prediction. J Intell Manuf 31, 1511–1529 (2020). https://doi.org/10.1007/s10845-019-01530-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10845-019-01530-8