Abstract

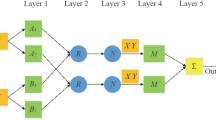

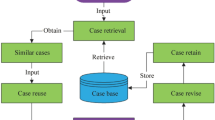

Compacted graphite iron (CGI) plays an important role in contemporary manufacturing of automobile engine, and coated tool is the best choice for milling of CGI. But studies about the estimation of the wear of coated tool are still rare and incomplete. As tool wear is the main factor that affects the quality of machined surface, in this study, we proposed an intelligent model-adaptive neuro fuzzy inference system (ANFIS) to estimate the tool wear, and ANFIS was learned by the improved particle swarm optimization (PSO) algorithm. As the PSO algorithm is easy to fall into the local minimum, the vibration and communication particle swarm optimization (VCPSO) algorithm was proposed by introducing the self-random vibration and inter-particle communication mechanisms. Besides that, to obtain the optimal combination of milling parameters, the multi-objective optimization based on minimum cutting power, surface roughness and maximum material removal rate (MRR) was studied using VCPSO algorithm. The experimental results showed that the ANFIS learned by VCPSO algorithm (ANFIS-VCPSO) has better performance for the estimation of tool wear compared with other intelligent models. The VCPSO algorithm was tested using Benchmark functions, and the results showed VCPSO algorithm has the global optimization ability. Meantime, the best combinations of milling parameters under different tool wear status were obtained through VCPSO algorithm. The proposed ANFIS-VCPSO model as a new intelligent model can be applied for real-time tool wear monitoring, which can improve the machining efficiency and prolong tool life. In order to meet the requirements of green and intelligent manufacturing, the best combination of milling parameters was also obtained in this work.

Similar content being viewed by others

References

Aydın, M., Karakuzu, C., Uçar, M., Cengiz, A., & Çavuşlu, M. A. (2013). Prediction of surface roughness and cutting zone temperature in dry turning processes of AISI304 stainless steel using ANFIS with PSO learning. International Journal of Advanced Manufacturing Technology. https://doi.org/10.1007/s00170-012-4540-2.

Cai, W. L., Zhang, W. J., Hu, X. F., & Liu, Y. C. (2020). A hybrid information model based on long short-term memory network for tool condition monitoring. Journal of Intelligent Manufacturing. https://doi.org/10.1007/s10845-019-01526-4.

Chegini, S. N., Bagheri, A., & Najafi, F. (2018). PSOSCALF: A new hybrid PSO based on Sine Cosine Algorithm and Levy flight for solving optimization problems. Applied Soft Computing, 73, 697–726. https://doi.org/10.1016/j.asoc.2018.09.019.

Dong, M. G., & Wang, N. (2011). Adaptive network-based fuzzy inference system with leave-one-out cross-validation approach for prediction of surface roughness. Applied Mathematical Modelling, 35, 1024–1035. https://doi.org/10.1016/j.apm.2010.07.048.

Eberhart, R. C., & Shi, Y. (2000). Comparing inertia weights and constriction factors in particle swarm optimization. Proceedings Congress on in Evolutionary Computation, 1, 84–88. https://doi.org/10.1109/CEC.2000.870279.

Ghosh, N., Ravi, Y. B., Patra, A., et al. (2007). Estimation of tool wear during CNC milling using neural network-based sensor fusion. Mechanical Systems and Signal Processing, 21, 466–479. https://doi.org/10.1016/j.ymssp.2005.10.010.

Gill, S. S., Singh, R., Singh, J., & Singh, H. (2012). Adaptive neuro-fuzzy inference system modeling of cryogenically treated AISI M2 HSS turning tool for estimation of flank wear. Expert Systems with Applications, 39, 4171–4180. https://doi.org/10.1016/j.eswa.2011.09.117.

Haber, R. E., Haber, R. H., Jimenez, A., & Galan, R. (2009). An optimal fuzzy control system in a network environment based on simulated annealing. An application to a drilling process. Applied Soft Computing, 9, 889–895. https://doi.org/10.1016/j.asoc.2008.11.005.

Hasanipanah, M., Amnieh, H. B., Arab, H., & Zamzam, M. S. (2018). Feasibility of PSO-ANFIS model to estimate rock fragmentation produced by mine blasting. Neural Computing and Applications, 30, 1015–1024. https://doi.org/10.1007/s00521-016-2746-1.

Hoanga, T. T., Cho, M. Y., Alamb, M. N., & Vu, Q. T. (2018). A novel differential particle swarm optimization for parameter selection of support vector machines for monitoring metal-oxide surge arrester conditions. Swarm and Evolutionary Computation, 38, 120–126. https://doi.org/10.1016/j.swevo.2017.07.006.

Hosoz, M., Ertunc, H. M., & Bulgurcu, H. (2011). An adaptive neuro-fuzzy inference system model for predicting the performance of a refrigeration system with a cooling tower. Expert Systems with Applications, 38, 14148–14155. https://doi.org/10.1016/j.eswa.2011.04.225.

Kaya, B., Oysu, C., & Ertunc, H. M. (2011). Force-torque based on-line tool wear estimation system for CNC milling of Inconel 718 using neural networks. Advances in Engineering Software, 42, 76–84. https://doi.org/10.1016/j.advengsoft.2010.12.002.

Kong, D. D., Chen, Y. J., Li, N., & Tan, S. L. (2016). Tool wear monitoring based on kernel principal component analysis and v-support vector regression. International Journal of Advanced Manufacturing Technology, 89(1-4), 175–190. https://doi.org/10.1007/s00170-016-9070-x.

Mathew, N. T., & Vijayaraghavan, L. (2017). Environmentally friendly drilling of intermet allictitanium aluminide at different aspect ratio. Journal of Cleaner Production, 141, 439–452. https://doi.org/10.1016/j.jclepro.2016.09.125.

Mohammadi, K., Shamshirband, S., Petkovic, D., Yee, P. L., & Mansor, Z. (2016). Using ANFIS for selection of more relevant parameters to predict dew point temperature. Applied Thermal Engineering, 96, 311–319. https://doi.org/10.1016/j.applthermaleng.2015.11.081.

Nam, J. S., Kim, D. H., Chung, H., & Lee, S. W. (2015). Optimization of environmentally benign micro-drilling process with nano fluid minimum quantity lubrication using response surface methodology and genetic algorithm. Journal of Cleaner Production, 102, 428–436. https://doi.org/10.1016/j.jclepro.2015.04.057.

Özel, T., & Karpat, Y. (2005). Predictive modeling of surface roughness and tool wear in hard turning using regression and neural networks. International Journal of Machine Tools and Manufacture, 45(4–5), 467–479. https://doi.org/10.1016/j.ijmachtools.2004.09.007.

Rizal, M., Ghani, J. A., Nuawi, M. Z., & Haron, C. H. C. (2013). Online tool wear prediction system in the turning process using an adaptive neuro-fuzzy inference system. Applied Soft Computing, 13, 1960–1968. https://doi.org/10.1016/j.asoc.2012.11.043.

Roy, S. S. (2005). Design of adaptive neuro-fuzzy inference system for predicting surface roughness in turning operation. Journal of Scientific & Industrial Research, 64(9), 653–659. https://doi.org/10.1088/0960-1317/15/9/S11.

Salgado, D. R., & Alonso, F. J. (2007). An approach based on current and sound signals for in-process tool wear monitoring. International Journal of Advanced Manufacturing Technology, 47(14), 2140–2152. https://doi.org/10.1016/j.ijmachtools.2007.04.013.

Sarkheyli, A., Zain, A. M., & Sharif, S. (2015). Robust optimization of ANFIS based on a new modified GA. Neurocomputing, 166, 357–366. https://doi.org/10.1016/j.neucom.2015.03.060.

Saw, L. B., Ho, L. W., Yew, M. C., & Yusof, F. (2018). Sensitivity analysis of drill wear and optimization using Adaptive Neuro fuzzy genetic algorithm technique toward sustainable machining. Journal of Cleaner Production, 172, 3289–3298. https://doi.org/10.1016/j.jclepro.2017.10.303.

Sharma, H., Bansal, J. C., & Arya, K. V. (2014). Self balanced differential evolution. Journal of Computational Science, 5, 312–323. https://doi.org/10.1016/j.jocs.2012.12.002.

Sharma, V. S., Sharma, S. K., & Sharma, A. K. (2008). Cutting tool wear estimation for turning. Journal of Intelligent Manufacturing, 19, 99–108. https://doi.org/10.1007/s10845-007-0048-2.

Shoorehdeli, M. A., et al. (2006). A novel training algorithm in ANFIS structure. In Proceedings of the 2006 American control conference (Vol. 6, pp. 5059–5064).

Sun, J., Hong, G. S., Rahman, M., & Wong, Y. S. (2007). Identification of feature set for effective tool condition monitoring by acoustic emission sensing. International Journal of Production Research, 42(5), 901–918. https://doi.org/10.1080/00207540310001626652.

Yuan, H., Wang, C. Y., & Zheng, L. J. (2014). Research development of compacted graphite iron machining. Machine Tool & Hydraulics, 42(13), 162–167. https://doi.org/10.3969/j.issn.1001-3881.2014.13.041.

Zhang, Z., et al. (2012). Study on the PSA-ANFIS approach for inverse design in slope engineering. In Proceedings of the 9th international conference on fuzzy systems and knowledge discovery (FSKD) (pp. 170–174). https://doi.org/10.1109/FSKD.2012.6234017.

Zou, C. L., Pang, J. C., Zhang, M. X., Qiu, Y., Li, S. X., et al. (2015). The high cycle fatigue, deformation and fracture of compacted graphite iron: Influence of temperature. Materials Science and Engineering A, 724, 606–615. https://doi.org/10.1016/j.msea.2018.01.025.

Acknowledgements

This work is financially supported by National Natural Science Foundation of China (51675312, 51675313).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Xu, L., Huang, C., Li, C. et al. Estimation of tool wear and optimization of cutting parameters based on novel ANFIS-PSO method toward intelligent machining. J Intell Manuf 32, 77–90 (2021). https://doi.org/10.1007/s10845-020-01559-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10845-020-01559-0