Abstract

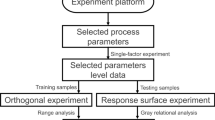

In the high speed milling process, the accurate predictions of surface roughness and residual stress can avoid the deterioration of machined surface quality. But it’s hard to estimate the surface roughness and residual stress under different tool wear status and cutting parameters. In this work, a novel intelligent reasoning method-improved case based reasoning (ICBR) was proposed to predict the surface roughness and residual stress. The inputs of ICBR are cutting parameters and tool wear status. The corresponding outputs of ICBR are surface roughness and residual stress. In the ICBR, K-nearest neighbor method and artificial neural network (ANN) as case retrieval was introduced to retrieve the K similar cases to the inputs. Through retrieving K similar cases, the Gaussian process regression (GPR) model as case reuse was established to output the surface roughness and residual stress. The vibration particle swarm optimization algorithm is proposed to optimize the ANN and GPR models. The high speed milling experiments of Compacted Graphite Iron was performed to validate the performance of ICBR. The experimental results showed that the cutting speed is the most important factor affecting the surface roughness. The feed rate is the most important factor affecting the residual stress. The ICBR gives the accurate estimation of surface roughness with the Mean Absolute Percentage Error of 11.6%. As for residual stress, the prediction accuracy using ICBR is 87.5%. Compared with Back-Propagation neural network, standard CBR and GPR models, the ICBR has better predictive performance and can be used for estimations of surface roughness and residual stress in the actual machining process.

Similar content being viewed by others

References

Aamodt, A., & Plaza, E. (1994). Case-based reasoning: Foundational issues, methodological variations, and system approaches. AI Communications, 7(1), 39–59.

Acheampong, A. O., & Boateng, E. B. (2019). Modelling carbon emission intensity: Application of artificial neural network. Journal of Cleaner Production, 225, 833–856. https://doi.org/10.1016/j.jclepro.2019.03.352.

Alam, S., Dobbie, G., Koh, Y. S., Riddle, P., & Rehman, S. U. (2014). Research on particle swarm optimization based clustering: A systematic review of literature and techniques. Swarm and Evolutionary Computation, 17, 1–13. https://doi.org/10.1016/j.swevo.2014.02.001.

Anthony, M. X., & Margret, S. A. (2012). Case-based reasoning (CBR) model for hard machining process. International Journal of Advanced Manufacturing Technology, 61, 1269–1275. https://doi.org/10.1007/s00170-012-4092-5.

Aydin, M., Karakuzu, C., Uçar, M., Cengiz, A., & Çavuşlu, M. A. (2013). Prediction of surface roughness and cutting zone temperature in dry turning processes of AISI304 stainless steel using ANFIS with PSO learning. International Journal of Advanced Manufacturing Technology, 67, 957–967. https://doi.org/10.1007/s00170-012-4540-2.

Ayeb, M., Frija, M., & Fathallah, R. (2019). Prediction of residual stress profile and optimization of surface conditions induced by laser shock peening process using artificial neural networks. International Journal of Advanced Manufacturing Technology, 100, 2455–2471.

Biswas, S. K., Sinha, N., Purakayastha, B., & Marbaniang, L. (2014). Hybrid expert system using case based reasoning and neural network for classification. Biologically Inspired Cognitive Architectures, 9, 57–70.

Cheng, G., & Zhong, Q. H. (2007). Adaptive case retrieval algorithm and application. Control Decision, 22(3), 357–360.

Deepa, S. N., & Sugumaran, G. (2011). Model order formulation of a multivariable discrete system using a modified particle swarm optimization approach. Swarm and Evolutionary Computation, 1, 204–212.

Feng, Y., Hung, T., Lu, Y. T., Lin, Y. F., et al. (2019). Residual stress prediction in laser-assisted milling considering recrystallization effects. International Journal of Advanced Manufacturing Technology, 102, 393–402.

Fern, F., Riverola, E., Diaz, F., et al. (2007). Reducing the memory size of a fuzzy case based reasoning system applying rough set techniques. IEEE Transactions on Systems, Man and Cybernetics. Part C: Applications and Reviews, 37(1), 138–146. https://doi.org/10.1109/TSMCC.2006.876058.

García Nieto, P. J., García-Gonzalo, E., Sánchez Lasheras, F., & De Cos Juez, F. J. (2011). Optimization of tile manufacturing process using particle swarm optimization. Swarm and Evolutionary Computation, 1, 97–109.

García Nieto, P. J., García-Gonzalo, E., Sánchez Lasheras, F., et al. (2015). Hybrid PSO-SVM-based method for forecasting of the remaining useful life for aircraft engines and evaluation of its reliability. Reliability Engineering & System Safety, 138, 219–231.

Ghosh, G., Mandal, P., & Mondal, S. C. (2019). Modeling and optimization of surface roughness in keyway milling using ANN, genetic algorithm, and particle swarm optimization. International Journal of Advanced Manufacturing Technology, 100(5), 1223–1242. https://doi.org/10.1007/s00170-017-1417-4.

Gu, D. X., Liang, C. Y., Bichindaritz, I., Zuo, C. R., & Wang, J. (2012). A case-based knowledge system for safety evaluation decision making of thermal power plants. Knowledge-Based Systems, 26(2), 185–195. https://doi.org/10.1016/j.knosys.2011.08.002.

Guo, Y., Hu, J., & Peng, Y. H. (2011). Research on CBR system based on data mining. Applied Soft Computing, 11(8), 5006–5014.

Han, M., & Cao, Z. J. (2015). An improved case-based reasoning method and its application in endpoint prediction of basic oxygen furnace. Neurocomputing, 149, 1245–1252.

Han, M., & Shen, L. H. (2011). Research of CBR based on particle swarm optimization. Control Decision, 26(4), 637–640.

Hasanipanah, M., Amnieh, H. B., Arab, H., & Zamzam, M. S. (2018). Feasibility of PSO-ANFIS model to estimate rock fragmentation produced by mine blasting. Neural Computing and Application, 30, 1015–1024.

Hyuk, I., & Sang, P. (2007). Case-based reasoning and neural network based expert system for personalization. Expert Systems with Applications, 32(3), 77–85.

Jiang, Z., Jiang, Y., Wang, Y., Zhang, H., Cao, H., & Tian, G. (2019). A hybrid approach of rough set and case-based reasoning to remanufacturing process planning. Journal of Intelligent Manufacturing, 30, 19–32.

Jung, S., Lim, T., & Kim, D. (2009). Integrating radial basis function networks with case-based reasoning for product design. Expert Systems with Applications, 36, 5695–5701.

Khosravani, M. R., & Nasiri, S. (2019). Injection molding manufacturing process: Review of case-based reasoning applications. Journal of Intelligent Manufacturing. https://doi.org/10.1007/s10845-019-01481-0.

Kong, D. D., Chen, Y. J., & Li, N. (2018). Gaussian process regression for tool wear prediction. Mechanical Systems and Signal Processing, 104, 556–574.

Li, G. F., Gu, Y. S., Kong, J. Y., Jiang, G. Z., & Xie, L. X. (2012). Intelligent control of coke oven air-fuel ratio. International Review on Computers and Software, 7(3), 1262–1267.

Lv, Z., Liu, Y., Jun Zhao, J., & Wei Wang, W. (2015). Soft computing for overflow particle size in grinding process based on hybrid case based reasoning. Applied Soft Computing, 27, 533–542. https://doi.org/10.1016/j.asoc.2014.09.035.

Mair, S., & Brefeld, U. (2018). Distributed robust Gaussian Process regression. Knowledge and Information Systems, 55(2), 415–435. https://doi.org/10.1007/s10115-017-1084-7.

Mathew, J., Griffin, M., & Alamaniotis, S. (2018). Prediction of welding residual stresses using machine learning: Comparison between neural networks and neuro-fuzzy systems. Applied Soft Computing, 70, 131–146.

Mok, S., & Kwong, C. (2002). Application of artificial neural network and fuzzy logic in a case-based reasoning for initial process parameter setting of injection molding. Journal of Intelligent Manufacturing, 13, 165–176.

Nasiri, S., Zahedi, G., Kuntz, S., & Fathi, M. (2019). Knowledge representation and management based on an ontological CBR system for dementia caregiving. Neurocomputing, 350, 181–194. https://doi.org/10.1016/j.neucom.2019.04.027.

Natarajan, U., Palani, S., & Anandampilai, B. (2012). Prediction of surface roughness in milling by machine vision using ANFIS. Computer-Aided Design and Applications, 9(3), 269–288. https://doi.org/10.3722/cadaps.2012.269-288.

Nayyar, V., Grenmyr, G., & Kaminski, J. (2013). Machinability of compacted graphite iron (CGI) and flake graphite iron (FGI) with coated carbide. International Journal of Machining and Machinability of Materials. https://doi.org/10.1504/ijmmm.2013.051909.

Niu, J., Huang, C., Su, R., Zou, B., Wang, J., Liu, Z., et al. (2019). Study on surface integrity of compacted graphite iron milled by cemented carbide tools and ceramic tools. International Journal of Advanced Manufacturing Technology, 103, 4123–4134. https://doi.org/10.1007/s00170-019-03592-7.

Oboudi, M. H., Hooshmand, R., & Karamad, A. (2017). A feasible method for controlled intentional islanding in microgrids based on PSO algorithm. Swarm and Evolutionary Computation., 35, 14–25. https://doi.org/10.1016/j.swevo.2017.02.003.

Reder, I. H., Urdiales, C., Peula, J. M., & Sandoval, F. (2017). CBR based reactive behavior learning for the memory-prediction framework. Neurocomputing, 250, 18–27. https://doi.org/10.1016/j.neucom.2016.10.075.

Relich, M., & Pawlewski, P. (2018). A case-based reasoning approach to cost estimation of new product development. Neurocomputing, 272, 40–45.

Steadman, S., & Pell, K. (1995). Expert systems in engineering design: An application for injection molding plastic parts. Journal of Intelligent Manufacturing, 6, 347–353.

Wang, X., Wang, W., Huang, Y., Nguyen, N., & Krishnakumar, K. (2008). Design of neural network-based estimator for tool wear modeling in hard turning. Journal of Intelligent Manufacturing, 19, 383–396.

Xu, B. T., Meng, X. L., Tian, A. Q., Sun, Y. J., Cao, L. B., & Jiang, Y. J. (2018). Prediction for state of charge of lead-acid battery by particle swarm optimization with Gaussian process regression. Journal of Nanjing University of Science and Technology, 42(02), 162–168.

Yan, A. J., Wang, W. X., & Zhang, C. X. (2014). A fault prediction method that uses improved case-based reasoning to continuously predict the status of a shaft furnace. Information Sciences, 259(2), 269–281.

Zhang, X. H., Deng, Z. H., Liu, W., & Cao, H. (2013). Combining rough set and case based reasoning for process conditions selection in camshaft grinding. Journal of Intelligent Manufacturing, 24, 211–224.

Zhao, H., Liu, J. W., Dong, W., Sun, X. Y., & Ji, Y. D. (2017). An improved case-based reasoning method and its application on fault diagnosis of Tennessee Eastman process. Neurocomputing, 249, 266–276. https://doi.org/10.1016/j.neucom.2017.04.022.

Acknowledgements

This work is financially supported by National Natural Science Foundation of China (51675312, 51675313).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Xu, L., Huang, C., Li, C. et al. An improved case based reasoning method and its application in estimation of surface quality toward intelligent machining. J Intell Manuf 32, 313–327 (2021). https://doi.org/10.1007/s10845-020-01573-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10845-020-01573-2