Abstract

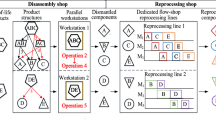

This study considers an integrated process planning and scheduling (IPPS) problem for remanufacturing systems incorporating parallel disassembly workstations, a flexible job-shop-type reprocessing shop, and parallel reassembly workstations. This IPPS problem aims to determine the allocation/sequence of end-of-life products on the disassembly/reassembly shops and make decisions on the process path selection, operation sequencing, workstation allocation, and selection for reprocessing jobs. To solve the problem, a mixed-integer programming model is first built to characterize it mathematically, and a novel extended network graph is designed to represent and solve this problem visually. Then, an improved artificial bee colony algorithm is proposed that can solve the IPPS problem of remanufacturing systems with disassembly, reworking and reassembly shops simultaneously. In this introduced algorithm, a 3-level real-number solution representation scheme is adopted for encoding and decoding processes, and efficient neighborhood search structures are designed to improve the quality and diversity of the population. Computational experiments were systematically conducted on serval test instances. The results show that the proposed algorithm is highly advantageous for solving the IPPS problems in the remanufacturing systems by comparing it with four baseline algorithms.

Similar content being viewed by others

References

Ahmad, R., & Plapper, P. (2016). Ant-air self-learning algorithm for path planning in a cluttered environment. International Journal of Materials, Mechanics and Manufacturing, 4(2), 127–130. https://doi.org/10.7763/IJMMM.2016.V4.239

Ahmad, R., Tichadou, S., & Hascoet, J. Y. (2017). A knowledge-based intelligent decision system for production planning. International Journal of Advanced Manufacturing Technology, 89(5–8), 1717–1729. https://doi.org/10.1007/s00170-016-9214-z

Barzanji, R., Naderi, B., & Begen, M. A. (2020). Decomposition algorithms for the integrated process planning and scheduling problem. Omega (united Kingdom), 93, 102025. https://doi.org/10.1016/j.omega.2019.01.003

Chen, D., Jiang, Z., Zhu, S., & Zhang, H. (2020). A knowledge-based method for eco-efficiency upgrading of remanufacturing process planning. International Journal of Advanced Manufacturing Technology, 108(4), 1153–1162. https://doi.org/10.1007/s00170-020-05025-2

Chryssolouris, G., Chan, S., & Suh, N. P. (1985). An integrated approach to process planning and scheduling. CIRP Annals - Manufacturing Technology, 34(1), 413–417. https://doi.org/10.1016/S0007-8506(07)61801-0

Daniel, V., & Guide, R., Jr. (1997). Scheduling with priority dispatching rules and drum-buffer-rope in a recoverable manufacturing system. International Journal of Production Economics, 53(1), 101–116. https://doi.org/10.1016/S0925-5273(97)00097-2

Ferrer, G. (1997). The economics of tire remanufacturing. Resources, Conservation and Recycling, 19(4), 221–255. https://doi.org/10.1016/S0921-3449(96)01181-0

Fu, Y., Zhou, M., Guo, X., & Qi, L. (2021). Stochastic multi-objective integrated disassembly-reprocessing-reassembly scheduling via fruit fly optimization algorithm. Journal of Cleaner Production, 278, 123364. https://doi.org/10.1016/j.jclepro.2020.123364

Gong, G., Deng, Q., Chiong, R., Gong, X., Huang, H., & Han, W. (2020). Remanufacturing-oriented process planning and scheduling: Mathematical modelling and evolutionary optimisation. International Journal of Production Research, 58(12), 3781–3799. https://doi.org/10.1080/00207543.2019.1634848

Guide, V. D. R. (1996). Scheduling using drum-buffer-rope in a remanufacturing environment. International Journal of Production Research, 34(4), 1081–1091. https://doi.org/10.1080/00207549608904951

Guide, V. D. R., Jr. (2000a). Production planning and control for remanufacturing: Industry practice and research needs. Journal of Operations Management, 18(4), 467–483. https://doi.org/10.1016/S0272-6963(00)00034-6

Guide, V. D. R. (2000b). Production planning and control for remanufacturing: industry practice and research needs. Journal of Operations Management, 18(4), 467–483. https://doi.org/10.1016/S0272-6963(00)00034-6

He, Y., Hao, C., Wang, Y., Li, Y., Wang, Y., Huang, L., & Tian, X. (2020). An ontology-based method of knowledge modelling for remanufacturing process planning. Journal of Cleaner Production, 258, 120952. https://doi.org/10.1016/j.jclepro.2020.120952

Jiang, Z., Jiang, Y., Wang, Y., Zhang, H., Cao, H., & Tian, G. (2019). A hybrid approach of rough set and case-based reasoning to remanufacturing process planning. Journal of Intelligent Manufacturing, 30(1), 19–32. https://doi.org/10.1007/s10845-016-1231-0

Jiang, Z., Zhou, T., Zhang, H., Wang, Y., Cao, H., & Tian, G. (2016). Reliability and cost optimization for remanufacturing process planning. Journal of Cleaner Production, 135, 1602–1610. https://doi.org/10.1016/j.jclepro.2015.11.037

Karaboga, D., & Akay, B. (2009). A comparative study of artificial bee colony algorithm. Applied Mathematics and Computation, 214(1), 108–132. https://doi.org/10.1016/j.amc.2009.03.090

Kim, E., & Van Oyen, M. P. (2021). Joint admission, production sequencing, and production rate control for a two-class make-to-order manufacturing system. Journal of Manufacturing Systems, 59, 413–425. https://doi.org/10.1016/j.jmsy.2021.03.010

Kim, J. M., Zhou, Y. D., & Lee, D. H. (2017). Priority scheduling to minimize the total tardiness for remanufacturing systems with flow-shop-type reprocessing lines. International Journal of Advanced Manufacturing Technology, 91(9–12), 3697–3708. https://doi.org/10.1007/s00170-017-0057-z

Kim, M. G., Yu, J. M., & Lee, D. H. (2015). Scheduling algorithms for remanufacturing systems with parallel flow-shop-type reprocessing lines. International Journal of Production Research, 53(6), 1819–1831. https://doi.org/10.1080/00207543.2014.962112

Kim, Y. K., Park, K., & Ko, J. (2003). A symbiotic evolutionary algorithm for the integration of process planning and job shop scheduling. Computers and Operations Research, 30(8), 1151–1171. https://doi.org/10.1016/S0305-0548(02)00063-1

Lage, M., Jr., & Filho, M. G. (2012). Production planning and control for remanufacturing: Literature review and analysis. Production Planning and Control, 23(6), 419–435. https://doi.org/10.1080/09537287.2011.561815

Le, V. T., Paris, H., & Mandil, G. (2017). Process planning for combined additive and subtractive manufacturing technologies in a remanufacturing context. Journal of Manufacturing Systems, 44, 243–254. https://doi.org/10.1016/j.jmsy.2017.06.003

Lee, C. Y., Lin, C. S., Uzsoy, R., & Wong, C. C. (1994). Implementation of a demand-pull system in a job shop environment. International Journal of Production Research, 32(12), 2915–2927. https://doi.org/10.1080/00207549408957108

Li, K., Deng, Q., Zhang, L., Fan, Q., Gong, G., & Ding, S. (2021). An effective MCTS-based algorithm for minimizing makespan in dynamic flexible job shop scheduling problem. Computers and Industrial Engineering, 155, 107211. https://doi.org/10.1016/j.cie.2021.107211

Li, W. D., & McMahon, C. A. (2007). A simulated annealing-based optimization approach for integrated process planning and scheduling. International Journal of Computer Integrated Manufacturing, 20(1), 80–95. https://doi.org/10.1080/09511920600667366

Li, X., Gao, L., Pan, Q., Wan, L., & Chao, K. M. (2019). An effective hybrid genetic algorithm and variable neighborhood search for integrated process planning and scheduling in a packaging machine workshop. IEEE Transactions on Systems, Man, and Cybernetics: Systems, 49(10), 1933–1945. https://doi.org/10.1109/TSMC.2018.2881686

Li, X., Gao, L., & Shao, X. (2012). An active learning genetic algorithm for integrated process planning and scheduling. Expert Systems with Applications, 39(8), 6683–6691. https://doi.org/10.1016/j.eswa.2011.11.074

Lian, K., Zhang, C., Gao, L., & Li, X. (2012). Integrated process planning and scheduling using an imperialist competitive algorithm. International Journal of Production Research, 50(15), 4326–4343. https://doi.org/10.1080/00207543.2011.622310

Lihong, Q., & Shengping, L. (2012). An improved genetic algorithm for integrated process planning and scheduling. International Journal of Advanced Manufacturing Technology, 58(5–8), 727–740. https://doi.org/10.1007/s00170-011-3409-0

Liu, Q., Li, X., Gao, L., & Li, Y. (2021). A modified genetic algorithm with new encoding and decoding methods for integrated process planning and scheduling problem. IEEE Transactions on Cybernetics, 51(9), 4429–4438. https://doi.org/10.1109/TCYB.2020.3026651

Liu, Z., Wang, J., Zhang, C., Chu, H., Ding, G., & Zhang, L. (2021). A hybrid genetic-particle swarm algorithm based on multilevel neighbourhood structure for flexible job shop scheduling problem. Computers and Operations Research, 135, 105431. https://doi.org/10.1016/j.cor.2021.105431

Lv, S., & Liu, W. (2016). A cross-entropy-based approach for joint process plan selection and scheduling optimization. Proceedings of the Institution of Mechanical Engineers, Part b: Journal of Engineering Manufacture, 230(8), 1525–1536. https://doi.org/10.1177/0954405416640697

Micale, R., La Fata, C. M., Enea, M., & La Scalia, G. (2021). Regenerative scheduling problem in engineer to order manufacturing: An economic assessment. Journal of Intelligent Manufacturing, 32(7), 1913–1925. https://doi.org/10.1007/s10845-020-01728-1

Pongchairerks, P., & Kachitvichyanukul, V. (2009). A two-level particle swarm optimization algorithm on job-shop scheduling problems. International Journal of Operational Research, 4(4), 390–411. https://doi.org/10.1504/IJOR.2009.023535

Portioli-Staudacher, A., & Tantardini, M. (2012). A lean-based ORR system for non-repetitive manufacturing. International Journal of Production Research, 50(12), 3257–3273. https://doi.org/10.1080/00207543.2011.564664

Qiu, S., Ming, X., Sallak, M., & Lu, J. (2021). Joint optimization of production and condition-based maintenance scheduling for make-to-order manufacturing systems. Computers and Industrial Engineering, 162, 107753. https://doi.org/10.1016/j.cie.2021.107753

Seo, Y., Hong, S., Jung, D., & Chung, N. (2020). A study on the performance restoration of torque converters for passenger Car 6-Speed automatic transmissions with remanufacturing process technology. International Journal of Automotive Technology, 21(4), 1061–1070. https://doi.org/10.1007/s12239-020-0100-1

Shi, J., Zhang, W., Zhang, S., Wang, W., Lin, J., & Feng, R. (2020). A new environment-aware scheduling method for remanufacturing system with non-dedicated reprocessing lines using improved flower pollination algorithm. Journal of Manufacturing Systems, 57, 94–108. https://doi.org/10.1016/j.jmsy.2020.08.006

Slomp, J., Bokhorst, J. A. C., & Germs, R. (2009). A lean production control system for high-variety/low-volume environments: A case study implementation. Production Planning and Control, 20(7), 586–595. https://doi.org/10.1080/09537280903086164

Stanfield, P. M., King, R. E., & Hodgson, T. J. (2006). Determining sequence and ready times in a remanufacturing system. IIE Transactions (institute of Industrial Engineers), 38(7), 565–575. https://doi.org/10.1080/07408170500371830

Wang, H., Jiang, Z., Zhang, X., Wang, Y., & Wang, Y. (2017). A fault feature characterization based method for remanufacturing process planning optimization. Journal of Cleaner Production, 161, 708–719. https://doi.org/10.1016/j.jclepro.2017.05.178

Wang, W., Mo, D. Y., Wang, Y., & Tseng, M. M. (2019). Assessing the cost structure of component reuse in a product family for remanufacturing. Journal of Intelligent Manufacturing, 30(2), 575–587. https://doi.org/10.1007/s10845-016-1267-1

Wang, W., Tian, G., Yuan, G., & Pham, D. T. (2021). Energy-time tradeoffs for remanufacturing system scheduling using an invasive weed optimization algorithm. Journal of Intelligent Manufacturing. https://doi.org/10.1007/s10845-021-01837-5

Wu, X., Peng, J., Xiao, X., & Wu, S. (2021). An effective approach for the dual-resource flexible job shop scheduling problem considering loading and unloading. Journal of Intelligent Manufacturing, 32(3), 707–728. https://doi.org/10.1007/s10845-020-01697-5

Xiao, G., & Huang, Y. (2019). Surface reconstruction of laser-cladding remanufacturing blade using in adaptive belt grinding. International Journal of Advanced Manufacturing Technology, 101, 3199–3211. https://doi.org/10.1007/s00170-019-03489-5

Yan, J., Liu, Z., Zhang, C., Zhang, T., Zhang, Y., & Yang, C. (2021). Research on flexible job shop scheduling under finite transportation conditions for digital twin workshop. Robotics and Computer-Integrated Manufacturing, 72, 102198. https://doi.org/10.1016/j.rcim.2021.102198

Yu, J. M., Kim, J. S., & Lee, D. H. (2011). Scheduling algorithms to minimise the total family flow time for job shops with job families. International Journal of Production Research, 49(22), 6885–6903. https://doi.org/10.1080/00207543.2010.507609

Yu, J. M., & Lee, D. H. (2018). Scheduling algorithms for job-shop-type remanufacturing systems with component matching requirement. Computers & Industrial Engineering, 120, 266–278. https://doi.org/10.1016/j.cie.2018.04.048

Zhang, B., Pan, Q. K., Gao, L., Meng, L. L., Li, X. Y., & Peng, K. K. (2020). A three-stage multiobjective approach based on decomposition for an energy-efficient hybrid flow shop scheduling problem. IEEE Transactions on Systems, Man, and Cybernetics: Systems, 50(12), 4984–4999. https://doi.org/10.1109/TSMC.2019.2916088

Zhang, L., & Wong, T. N. (2016). Solving integrated process planning and scheduling problem with constructive meta-heuristics. Information Sciences, 340–341, 1–16. https://doi.org/10.1016/j.ins.2016.01.001

Zhang, R., Ong, S. K., & Nee, A. Y. C. (2015). A simulation-based genetic algorithm approach for remanufacturing process planning and scheduling. Applied Soft Computing Journal, 37(521–532), 3176. https://doi.org/10.1016/j.asoc.2015.08.051

Zhang, S., & Wong, T. N. (2018). Integrated process planning and scheduling: An enhanced ant colony optimization heuristic with parameter tuning. Journal of Intelligent Manufacturing, 29(3), 585–601. https://doi.org/10.1007/s10845-014-1023-3

Zhang, X., Liao, Z., Ma, L., & Yao, J. (2020). Hierarchical multistrategy genetic algorithm for integrated process planning and scheduling. Journal of Intelligent Manufacturing, 33, 223–246. https://doi.org/10.1007/s10845-020-01659-x

Zheng, P., Wang, J., Zhang, J., Yang, C., & Jin, Y. (2019). An adaptive CGAN/IRF-based rescheduling strategy for aircraft parts remanufacturing system under dynamic environment. Robotics and Computer-Integrated Manufacturing, 58, 230–238. https://doi.org/10.1016/j.rcim.2019.02.008

Zheng, Y., & Ahmad, R. (2020). Feature extraction and process planning of integrated hybrid additive-subtractive system for remanufacturing. Mathematical Biosciences and Engineering, 17(6), 7274–7301. https://doi.org/10.3934/MBE.2020373

Zheng, Y., Liu, J., & Ahmad, R. (2020). A cost-driven process planning method for hybrid additive–subtractive remanufacturing. Journal of Manufacturing Systems, 55, 248–263. https://doi.org/10.1016/j.jmsy.2020.03.006

Zheng, Y., Mamledesai, H., Imam, H., & Ahmad, R. (2021). A novel deep learning-based automatic damage detection and localization method for remanufacturing/repair. Computer-Aided Design and Applications, 18(6), 1359–1372. https://doi.org/10.14733/cadaps.2021.1359-1372

Zheng, Y., Qureshi, A. J., & Ahmad, R. (2018). Algorithm for remanufacturing of damaged parts with hybrid 3D printing and machining process. Manufacturing Letters, 15, 38–41. https://doi.org/10.1016/j.mfglet.2018.02.010

Acknowledgements

We express our gratitude and acknowledge the support of the China Scholarship Council (Grant No. 202006130018) and the NSERC Canada (Grant Nos. NSERC RGPIN-2017-04516 and NSERC ALLRP 545537-19) for funding this project.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

All the authors have no conflict in interest about this work.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhang, W., Zheng, Y. & Ahmad, R. The integrated process planning and scheduling of flexible job-shop-type remanufacturing systems using improved artificial bee colony algorithm. J Intell Manuf 34, 2963–2988 (2023). https://doi.org/10.1007/s10845-022-01969-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10845-022-01969-2