Abstract

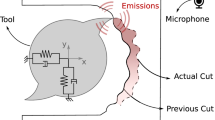

Regenerative chatter in machining operations such as milling is a common process anomaly that limits productivity and part quality, which in turn lead to increased manufacturing costs. The industrial relevance of the problem has sparked many research efforts over the recent decades, with a growing interest in real-time chatter detection and suppression. Inspired by learning from human demonstration frameworks, this paper proposes a new approach to milling chatter detection via effective human–machine interaction, which facilitates knowledge transfer from an experienced machine tool operator to a “Digital Apprentice.” The proposed chatter detection approach acquires chatter-specific knowledge through a learnable skill primitive (LSP) algorithm designed to establish a robust chatter detection threshold from few-shot real-time demonstrations by an experienced human operator. In this work, digital audio data were acquired from milling experiments through a microphone mounted inside the milling machine. During the training phase, data for the human operator’s natural reaction to chatter were collected via a specially designed human–machine interface. The learned chatter detection thresholds were obtained via the LSP algorithm by temporally mapping the reaction time data to the audio signal. During the testing phase, experiments were conducted to validate the detection accuracy and detection speed of the learned chatter detection thresholds under different cutting conditions. The experimental validation results of the learned thresholds indicate an average chatter detection accuracy of 94.4%, with 55.6% of chatter cases detected before chatter marks are produced on a 4140 Steel workpiece, thus demonstrating the effectiveness of human–machine interaction in chatter detection.

Similar content being viewed by others

References

Altintaş, Y., & Budak, E. (1995). Analytical prediction of stability lobes in milling. CIRP Annals, 44(1), 357–362.

Altintas, Y., & Chan, P. K. (1992). In-process detection and suppression of chatter in milling. International Journal of Machine Tools and Manufacture, 32(3), 329–347.

Argall, B. D., Chernova, S., Veloso, M., & Browning, B. (2009). A survey of robot learning from demonstration. Robotics and Autonomous Systems, 57(5), 469–483.

Aslan, D., & Altintas, Y. (2018). On-line chatter detection in milling using drive motor current commands extracted from CNC. International Journal of Machine Tools and Manufacture, 132, 64–80.

Bachrathy, D., Sykora, H. T., Hajdu, D., Beri, B., & Stepan, G. (2021). Why is it hard to identify the onset of chatter? A stochastic resonance perspective. CIRP Annals, 70, 329.

Berger, B., Minis, I., Rokni, M., Papadopoulos, M., Deng, K., & Chavalli, A. (1997). Cutting state identification. Journal of Sound and Vibration, 200(1), 15–29.

Caixu, Y., Haining, G., Xianli, L., Liang, S. Y., & Lihui, W. (2019). A review of chatter vibration research in milling. Chinese Journal of Aeronautics, 32(2), 215–242.

Cao, H., Yue, Y., Chen, X., & Zhang, X. (2017). Chatter detection in milling process based on synchrosqueezing transform of sound signals. The International Journal of Advanced Manufacturing Technology, 89(9), 2747–2755.

Cen, L., Melkote, S. N., Castle, J., & Appelman, H. (2018). A method for mode coupling chatter detection and suppression in robotic milling. Journal of Manufacturing Science and Engineering. https://doi.org/10.1115/1.4040161

Chernova, S., & Thomaz, A. L. (2014). Robot learning from human teachers. Synthesis Lectures on Artificial Intelligence and Machine Learning, 8(3), 1–121.

Delio, T. (1989). A sensor-based adaptive control constraint system for automatic spindle speed regulation to obtain highly stable milling. (Doctor of Philosophy Dissertation), University of Florida.

Delio, T., Tlusty, J., & Smith, S. (1992). Use of audio signals for chatter detection and control. Journal of manufacturing science and engineering, 114(2).

Ding, L., Sun, Y., & Xiong, Z. (2017). Early chatter detection based on logistic regression with time and frequency domain features. Paper presented at the 2017 IEEE International Conference on Advanced Intelligent Mechatronics (AIM).

Duncan, G., Schmitz, T. L., & Kurdi, M. H. (2000). Uncertainty propagation for selected analytical milling stability limit analyses: Society of Manufacturing Engineers.

Faassen, R., Doppenberg, E., van de Wouw, N., Oosterling, J., & Nijmeijer, H. (2006). Online detection of the onset and occurrence of machine tool chatter in the milling process. Paper presented at the CIRP 2nd International Conference on High Performance Cutting.

Jardine, A. K., Lin, D., & Banjevic, D. (2006). A review on machinery diagnostics and prognostics implementing condition-based maintenance. Mechanical Systems and Signal Processing, 20(7), 1483–1510.

Khorasani, A. M., Littlefair, G., & Goldberg, M. (2014). Time domain vibration signal processing on milling process for chatter detection. Journal of Machining and Forming Technologies, 6(1/2), 45.

Knox, W. B., & Stone, P. (2008). Tamer: Training an agent manually via evaluative reinforcement. Paper presented at the 2008 7th IEEE International Conference on Development and Learning.

Knox, W. B., & Stone, P. (2009). Interactively shaping agents via human reinforcement: The TAMER framework. Paper presented at the Proceedings of the Fifth International Conference on Knowledge Capture.

Kuljanic, E., Sortino, M., & Totis, G. (2008). Multisensor approaches for chatter detection in milling. Journal of Sound and Vibration, 312(4–5), 672–693.

Lamraoui, M., El Badaoui, M., & Guillet, F. (2015). Chatter detection in CNC milling processes based on Wiener-SVM approach and using only motor current signals. In Vibration engineering and technology of machinery (pp. 567–578). Springer.

Liao, Y., & Young, Y. (1996). A new on-line spindle speed regulation strategy for chatter control. International Journal of Machine Tools and Manufacture, 36(5), 651–660.

Liu, C., Zhu, L., & Ni, C. (2017). The chatter identification in end milling based on combining EMD and WPD. The International Journal of Advanced Manufacturing Technology, 91(9), 3339–3348.

Liu, H., Chen, Q., Li, B., Mao, X., Mao, K., & Peng, F. (2011). On-line chatter detection using servo motor current signal in turning. Science China Technological Sciences, 54(12), 3119–3129.

Luo, M., Luo, H., Axinte, D., Liu, D., Mei, J., & Liao, Z. (2018). A wireless instrumented milling cutter system with embedded PVDF sensors. Mechanical Systems and Signal Processing, 110, 556–568.

Ma, L., Melkote, S. N., & Castle, J. B. (2013). A model-based computationally efficient method for on-line detection of chatter in milling. Journal of Manufacturing Science and Engineering, 135(3), 031007.

Ma, L., Melkote, S. N., & Castle, J. B. (2014). PVDF sensor-based monitoring of milling torque. The International Journal of Advanced Manufacturing Technology, 70(9–12), 1603–1614.

Melkote, S. (2020). Georgia Institute of Technology Institutional Review Board Protocol H20340. In Study of Human's Reaction Time to Anomalies in Manufacturing Operations. Georgia Institute of Technology: Georgia Institute of Technology.

Nehaniv, C. L., & Dautenhahn, K. (2002). The correspondence problem. In Imitation in animals and artifacts (p. 41).

Nguyen, V., Melkote, S., Deshamudre, A., Khanna, M., & Walker, D. (2016). Comparison of on-line chatter detection algorithms in turning. Paper presented at the 2016 International Symposium on Flexible Automation (ISFA).

Palmer, E. M., Horowitz, T. S., Torralba, A., & Wolfe, J. M. (2011). What are the shapes of response time distributions in visual search? Journal of Experimental Psychology: Human Perception and Performance, 37(1), 58.

Pham, H. (2006, 2017). PyAudio 0.2.11. https://pypi.org/project/PyAudio/

Quintana, G., & Ciurana, J. (2011). Chatter in machining processes: A review. International Journal of Machine Tools and Manufacture, 51(5), 363–376.

Rahimi, M. H., Huynh, H. N., & Altintas, Y. (2021). On-line chatter detection in milling with hybrid machine learning and physics-based model. CIRP Journal of Manufacturing Science and Technology, 35, 25–40.

Schaal, S. (1997). Learning from demonstration. Paper presented at the Advances in Neural Information Processing Systems.

Schaal, S. (2006). Dynamic movement primitives-a framework for motor control in humans and humanoid robotics. In Adaptive motion of animals and machines (pp. 261–280). Springer.

Schaal, S., Peters, J., Nakanishi, J., & Ijspeert, A. (2003). Control, planning, learning, and imitation with dynamic movement primitives. Paper presented at the Workshop on Bilateral Paradigms on Humans and Humanoids: IEEE International Conference on Intelligent Robots and Systems (IROS 2003).

Schmitz, T. L., Medicus, K., & Dutterer, B. (2002). Exploring once-per-revolution audio signal variance as a chatter indicator. Machining Science and Technology, 6(2), 215–233.

Shi, F., Cao, H., Wang, Y., Feng, B., & Ding, Y. (2020). Chatter detection in high-speed milling processes based on ON-LSTM and PBT. The International Journal of Advanced Manufacturing Technology, 111(11), 3361–3378.

Smith, S., & Tlusty, J. (1991). An overview of modeling and simulation of the milling process. Journal of Manufacturing Science and Engineering, 113(2), 169.

Smith, S., & Tlusty, J. (1993). Efficient simulation programs for chatter in milling. CIRP Annals, 42(1), 463–466.

Tlusty, J., & Polacek, M. (1968). Experience with analysing stability of machine tool against chatter. Paper presented at the 9th MTDR Conference.

Tobias, S. (1964). Vibration of machine tools. Production Engineer, 43(12), 599–608.

Tran, M.-Q., Liu, M.-K., & Tran, Q.-V. (2020). Milling chatter detection using scalogram and deep convolutional neural network. The International Journal of Advanced Manufacturing Technology, 107(3), 1505–1516.

Warnell, G., Waytowich, N., Lawhern, V., & Stone, P. (2018). Deep tamer: Interactive agent shaping in high-dimensional state spaces. Paper presented at the Proceedings of the AAAI Conference on Artificial Intelligence.

Wright, P. K., & Bourne, D. A. (1988). Manufacturing intelligence. Addison-Wesley Longman Publishing Co., Inc.

Yao, Z., Mei, D., & Chen, Z. (2010). On-line chatter detection and identification based on wavelet and support vector machine. Journal of Materials Processing Technology, 210(5), 713–719.

Yesilli, M. C., Khasawneh, F. A., & Otto, A. (2020). On transfer learning for chatter detection in turning using wavelet packet transform and ensemble empirical mode decomposition. CIRP Journal of Manufacturing Science and Technology, 28, 118–135.

Yuqing, Z., Xinfang, L., Fengping, L., Bingtao, S., & Wei, X. (2015). An online damage identification approach for numerical control machine tools based on data fusion using vibration signals. Journal of Vibration and Control, 21(15), 2925–2936.

Zhang, C. L., Yue, X., Jiang, Y. T., & Zheng, W. (2010). A hybrid approach of ANN and HMM for cutting chatter monitoring. Paper presented at the Advanced Materials Research.

Acknowledgements

This work was supported by Siemens Corporation, Corporate Technology through the Siemens Fellowship.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interests

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Yan, X., Melkote, S., Mishra, A.K. et al. A digital apprentice for chatter detection in machining via human–machine interaction. J Intell Manuf 34, 3039–3052 (2023). https://doi.org/10.1007/s10845-022-01992-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10845-022-01992-3