Abstract

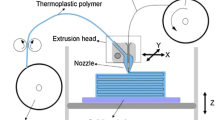

Additive manufacturing is typically an open-loop process. Consequently, it results in poor material matching at the junctions in multimaterial printing, affecting the performance of functional components. This study investigated the surface accumulation characteristics of parts in three-dimensional (3D) inkjet printing. Moreover, an intelligent additive manufacturing system for array nozzles was developed to improve the material accumulation accuracy and printing efficiency. First, a height prediction model was established to predict the printing height information, and a P-type closed-loop iterative learning control compensation algorithm with initial value correction was formulated based on the layer thickness experimental data. This algorithm reduced the root-mean-squared error (RMSE) of the sample’s surface by 69.3%. Second, a set of random offset nozzle compensation algorithms was developed and combined with the laser vision scanning method to obtain the nozzle clogging information and compensate for sample defects by adjusting the parameters of the random algorithm. Finally, a microstrip antenna was fabricated. The surface roughness of the sample in this study was lower than that of the open-loop printed sample, resulting in a good antenna radio frequency (RF) layer connection. In addition, the S11 parameters were closer to the simulation results. These results validate the significance of this research in electronic printing.

Similar content being viewed by others

Abbreviations

- 3D:

-

Three-dimensional

- AM:

-

Additive manufacturing

- RMSE:

-

Root-mean-squared error

References

Aimerbtam, N., & Panjapornpon, C. (2017), Monitoring and control of droplet size in a micro-channel reactor for biodiesel production. In 2017 IEEE Conference on Systems, Process and Control (ICSPC), Meleka

Amendola, S., Palombi, A., & Marrocco, G. (2018). Inkjet printing of epidermal RFID antennas by self-sintering conductive Ink. IEEE Transactions on Microwave Theory and Techniques, 66(3), 1561–1569.

Barton, K., Mishra, S., & Alleyne, A. (2011). Control of high-resolution electrohydrodynamic jet printing. Control Engineering Practice, 19(11), 1266–1273.

Chen, H. Y., & Liang, J. W. (2014). Piezoelectric-actuated drop-on-demand droplet generator control using adaptive wavelet neural network controller. Journal of Process Control, 24(5), 578–585.

Cohen, D. L., & Lipson, H. (2010). Geometric feedback control of discrete-deposition SFF systems. Rapid Prototyping Journal, 16(5), 377–393.

Derby, B. (2011). Inkjet printing ceramics: From drops to solid. Journal of the European Ceramic Society, 31(14), 2543–2550.

Dongdong, G., Xinyu, S., Reinhart, P., David, L. B., Rossitza, S., & Jihong, Z. (2021). Material-structure-performance integrated laser-metal additive manufacturing. Science, 372(6545), eabg1487.

Dongwoon, S., Sun, C., Jonghyun, K., Abiral, R., & Jiyoung, C. (2020). Direct-printing of functional nanofibers on 3D surfaces using self-aligning nanojet in near-field electrospinning. Advanced Materials Technologies, 5(6), 2000232.

Doumanidis, C., & Skordeli, E. (2000). Distributed-parameter modeling for geometry control of manufacturing processes with material deposition. Journal of Dynamical Systems, Measurment, and Control, 122(1), 71–77.

Fanbo, M., Jin, H., & Pengbing, Z. (2020). Closed-loop optimized nanometal sintering method. Journal of Manufacturing Processes, 59, 403–410.

Fanbo, M., Mingchang, Z., & Jin, H. (2021). Additive manufacturing of stable energy storage devices using a multi-nozzle printing system. Advanced Functional Materials, 31, 2008280.

Guo, Y., & Mishra, S. (2016). A predictive control algorithm for layer-to-layer ink-jet 3D printing. In American Control Conference (ACC). Boston: IEEE.

Guo, Y., Peters, J., & Oomen, T. (2018). Control-oriented models for ink-jet 3D printing. Mechatrons, 56, 211–219.

Huang, S. H., Liu, P., & Mokasdar, A. (2013). Additive manufacturing and its societal impact: A literature review. International Journal of Advanced Manufacturing Technology, 67, 1191–1203.

Huang, Q., Zhang, J., & Sabbaghi, A. (2015). Optimal offline compensation of shape shrinkage for three-dimensional printing processes. Iie Transactions, 47(5), 431–441.

Inyang-Udoh, U., Guo, Y., & Peters, J. (2020). Layer-to-layer predictive control of inkjet 3-D printing. IEEE-Asme Transactions on Mechatronics, 25(4), 1783–1793.

Jin, Y. A., He, Y., & Gao, Q. (2014). Droplet deviation modeling and compensation scheme of inkjet printing. International Journal of Advanced Manufacturing Technology, 75, 1405–1415.

Lewis, J. A., & Ahn, B. Y. (2015). Device fabrication: Three-dimensional printed electronics. Nature, 518(7537), 42–43.

Lu, B., & Li, D. (2013). Development of additive manufacturing (3D printing) technology. Machine Building & Automation, 42(4), 1–4.

Lu, L., Zheng, J., & Mishra, S. (2014a). A layer-to-layer model and feedback control of ink-jet 3-D printing. Ieee/asme Transactions on Mechatronics, 20(3), 1056–1068.

Lu, L., Zheng, J., & Mishra, S. (2014b). A model-based layer-to-layer control algorithm for ink-jet 3D printing. In Dynamic systems and control conference. American Society of Mechanical Engineers, Texas

Mosadegh, B., Xiong, G., & Dunham, S. (2015). Current progress in 3D printing for cardiovascular tissue engineering. Biomedical Materials, 10(3), 034002.

Sadeghian, H., Hojjat, Y., & Ghodsi, M. (2014). An approach to design and fabrication of a piezo-actuated microdroplet generator. International Journal of Advanced Manufacturing Technology, 70, 1091–1099.

Wassink, M., Bosch, N., & Bosgra, O. (2005). Enabling higher jet frequencies for an inkjet printhead using iterative learning control. In Proceedings of the 2005 IEEE conference on control applications, Toronto.

Yang, H., Leow, W. R., & Chen, X. (2018). 3D printing of flexible electronic devices. Small Methods, 2(1), 1700259.

Yuan, X., & Xiong, Z. (2018). High frequency pulsed electrohydrodynamic printing with controllable fine droplets. Journal of Micromechanics and Microengineering, 28(9), 095008.

Funding

This work was supported by the Natural Science Foundation of Shaanxi Province (2022JQ-366), National Natural Science Foundation of China (Nos. 52205411, 52035010, 51775405, 51905403, 51875431), Shaanxi Innovation Team Project (No. 2018TD-012), Shaanxi Key Industry Chain Project (No. 2020ZDLGY14-08), and the National 111 Project (No. B14042).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Meng, F., Huang, J., Ping, B. et al. Intelligent control system for 3D inkjet printing. J Intell Manuf 35, 575–586 (2024). https://doi.org/10.1007/s10845-022-02061-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10845-022-02061-5