Abstract

To satisfy the requirements of individual design and rapid performance evaluation of complex products, this paper proposes a hybrid approach to build a performance evaluation model and perform the rapid evaluation of design schemes. This approach consists of a surrogate model and knowledge graph (KG). Firstly, the KG of complex electromechanical products is established by Web Ontology Language to provide information about parts and evaluation indexes for the sampling process. It includes building ontology and writing inference and query rules at the framework level. Secondly, based on the sample points, a dynamics model is built and used for simulation. Using the Design of Experiments, the variables that have the greatest impact are found. The relevant variables will be input into the model to obtain the data set. According to the data set, a surrogate model based on the radial basis function is built as a performance evaluation model, which can improve computing efficiency to achieve evaluation results rapidly. In this study, the bogie design is used as a test case to evaluate the proposed method. And the results show that it can improve design efficiency for design issues such as part selection.

Similar content being viewed by others

Data availability

The data that support the findings of this study are available from the corresponding author, Guijie Liu or Honghui Wang upon reasonable request.

References

Abadi, A., Ben-Azza, H., & Sekkat, S. (2018). Improving integrated product design using SWRL rules expression and ontology-based reasoning. Procedia Computer Science, 127, 416–425.

Bastinos, A. Š, & Krisper, M. (2013). Multi-criteria decision making in ontologies. Information Sciences, 222, 593–610.

Chen, X., Jia, S., & Xiang, Y. (2020). A review: Knowledge reasoning over knowledge graph. Expert Systems with Applications, 141, 112948.

Cheng, W., Kasneci, G., Graepel, T., Stern, D., & Herbrich, R. (2011). Automated feature generation from structured knowledge. Paper presented at the Proceedings of the 20th ACM international conference on Information and knowledge management. https://doi.org/10.1145/2063576.2063779

Díaz-Manríquez, A., Toscano, G., & Coello Coello, C. A. (2017). Comparison of metamodeling techniques in evolutionary algorithms. Soft Computing, 21, 5647–5663. https://doi.org/10.1007/s00500-016-2140-z

Eum, K., Kang, M., Kim, G., Park, M. W., & Kim, J. K. (2013). Ontology-based modeling of process selection knowledge for machining feature. International Journal of Precision Engineering and Manufacturing, 14(10), 1719–1726. https://doi.org/10.1007/s12541-013-0231-7

Guo, L., Yan, F., Li, T., Yang, T., & Lu, Y. (2022). An automatic method for constructing machining process knowledge base from knowledge graph. Robotics and Computer-Integrated Manufacturing, 73, 102222.

Hogan, A., Blomqvist, E., Cochez, M., d’Amato, C., Melo, G. D., Gutierrez, C., Kirrane, S., Gayo, J. E., Navigli, R., Neumaier, S., & Ngomo, A. C. (2021). Knowledge graphs. ACM Computing Surveys (CSUR), 54(4), 1–37. https://doi.org/10.1145/3447772

Hosder, S., Watson, L. T., Grossman, B., Mason, W. H., Kim, H., Haftka, R. T., & Cox, S. E. (2001). Polynomial response surface approximations for the multidisciplinary design optimization of a high speed civil transport. Optimization and Engineering, 2(4), 431–452. https://doi.org/10.1023/A:1016094522761

Huai-long, S., Ren, L., & Jing, Z. (2021). Review on domestic and foreign dynamics evaluation criteria of high-speed train. Journal of Traffic and Transportation Engineering, 21(1), 36. https://doi.org/10.19818/j.cnki.1671-1637.2021.01.002

Kamath, C. (2022). Intelligent sampling for surrogate modeling, hyperparameter optimization, and data analysis. Machine Learning with Applications, 9, 100373.

Lin, D. K., Simpson, T. W., & Chen, W. (2001). Sampling strategies for computer experiments: design and analysis. International Journal of Reliability and Applications, 2(3), 209–240.

O’Connor, M. J., & Das, A. K. (2009). SQWRL: a query language for OWL. Paper presented at the OWLED. https://ceur-ws.org/Vol-529/owled2009_submission_42.pdf

Panwar, V., Sharma, D. K., Kumar, K. P., Jain, A., & Thakar, C. (2021). Experimental investigations and optimization of surface roughness in turning of en 36 alloy steel using response surface methodology and genetic algorithm. Materials Today: Proceedings, 46, 6474–6481.

Thombre, M. N., Preisig, H. A., & Addis, M. B. (2015). Developing surrogate models via computer based experiments. In Computer Aided Chemical Engineering (Vol. 37, pp. 641–646): Elsevier

Tiwari, S., Al-Aswadi, F. N., & Gaurav, D. (2021). Recent trends in knowledge graphs: theory and practice. Soft Computing, 25, 8337–8355. https://doi.org/10.1007/s00500-021-05756-8

Tseranidis, S., Brown, N. C., & Mueller, C. T. (2016). Data-driven approximation algorithms for rapid performance evaluation and optimization of civil structures. Automation in Construction, 72, 279–293.

Wan, S., Li, D., Gao, J., & Li, J. (2019). A knowledge based machine tool maintenance planning system using case-based reasoning techniques. Robotics and Computer-Integrated Manufacturing, 58, 80–96.

Wang, H., Xu, X., Zhang, C., & Hu, T. (2018). A hybrid approach to energy-efficient machining for milled components via STEP-NC. International Journal of Computer Integrated Manufacturing, 31(4–5), 442–456. https://doi.org/10.1080/0951192X.2017.1322220

Wang, X., Xia, Z., Zhou, X., Guo, Y., Gu, X., & Yan, H. (2021). Multiobjective path optimization for arc welding robot based on dmoea/d-et algorithm and proxy model. IEEE Transactions on Instrumentation and Measurement, 70, 1–13.

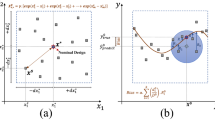

Wang, Z., & Wang, P. (2014). A maximum confidence enhancement based sequential sampling scheme for simulation-based design. Journal of Mechanical Design, 136(2), 021006.

Yahya, M., Breslin, J. G., & Ali, M. I. (2021). Semantic web and knowledge graphs for industry 4.0. Applied Sciences, 11(11), 5110.

Zhang, B., Wang, Q., Liu, X., Zu, L., & Yuan, H. (2022). Aeroelastic optimization design of composite materials blade based on RBF/ROM and CCA reliability analysis. Composite Structures, 300, 116162.

Zhang, Y., Luo, X., Zhang, H., & Sutherland, J. W. (2014). A knowledge representation for unit manufacturing processes. The International Journal of Advanced Manufacturing Technology, 73, 1011–1031. https://doi.org/10.1007/s00170-014-5864-x

Zhang, Z., Cao, L., Chen, X., Tang, W., Xu, Z., & Meng, Y. (2020). Representation learning of knowledge graphs with entity attributes. IEEE Access, 8, 7435–7441.

Zhao, D., Ma, M., & You, X.-Y. (2022). A Kriging-based adaptive parallel sampling approach with threshold value. Structural and Multidisciplinary Optimization, 65(8), 225. https://doi.org/10.1007/s00158-022-03310-0

Zheng, H., Feng, Y., Gao, Y., & Tan, J. (2018). A robust predicted performance analysis approach for data-driven product development in the industrial internet of things. Sensors, 18(9), 2871.

Zheng, P., Xia, L., Li, C., Li, X., & Liu, B. (2021). Towards Self-X cognitive manufacturing network: An industrial knowledge graph-based multi-agent reinforcement learning approach. Journal of Manufacturing Systems, 61, 16–26.

Zhou, B., Bao, J., Li, J., Lu, Y., Liu, T., & Zhang, Q. (2021). A novel knowledge graph-based optimization approach for resource allocation in discrete manufacturing workshops. Robotics and Computer-Integrated Manufacturing, 71, 102160.

Zou, H., Wu, Q., & Zou, X. (2022). Research on optimization design of suspension parameters of railway vehicle bogies based on surrogate model. Multimedia Tools and Applications. https://doi.org/10.1007/s11042-022-14022-4

Acknowledgements

The authors gratefully acknowledge the financial support of National Key Research and Development Program of China (Grant No. 2020YFB1708003), and the Taishan Scholars Program of Shandong Province No. ts20190914.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

All authors declare that they have no conflicts of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Han, X., Liu, X., Wang, H. et al. A performance evaluation method based on combination of knowledge graph and surrogate model. J Intell Manuf 35, 3441–3457 (2024). https://doi.org/10.1007/s10845-023-02210-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10845-023-02210-4