Abstract

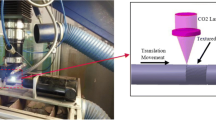

The prediction of surface roughness is important for all materials that undergo manufacturing processes. The Ti6Al4V titanium alloy is commonly used in aerospace, automotive and power generation industries but also in the manufacturing of medical implants, mainly because of its biocompatibility. Here we study the relationship of Ti6Al4V’s surface roughness with critical machining parameters and conditions based on experimental input (machining parameters)-output (surface roughness) data derived during the turning operation. The experimental findings are converted into polynomial models through the Response Surface Methodology (RSM) and into a fuzzy logic system through the Adaptive Neuro-Fuzzy Inference System (ANFIS). The ability of these two methodologies to predict Ti6Al4V’s surface roughness when machined is presented and compared. It is observed that the ANFIS predicts surface roughness with less error mainly when the data used for evaluation are not completely different to those used for training.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.References

Abele, E., Fröhlich, B.: High speed milling of titanium alloys. Adv. Production Engineering Management 3, 131–140 (2008)

Anselme, K., Linez, P., Bigerelle, M., Le Maguer, D., Le Maguer, A., Hardouin, P., Hildebrand, H.F., Iost, A., Leroy, J.M.: The relative influence of the topography and chemistry of Ti6Al4V surfaces on osteoblastic cell behaviour. Biomaterials 21, 1567–1577 (2000)

Benardos, P.G., Vosniakos, G.C.: Predicting surface roughness in machining: a review. Int. J. Mach. Tools Manuf. 43, 833–844 (2003)

Brezocnik, M., Kovacic, M., Ficko, M.: Prediction of surface roughness with genetic programming. J. Mater. Process. Technol. 157, 28–36 (2004)

Che-Haron, C.H., Jawaid, A.: The effect of machining on surface integrity of titanium alloy Ti–6% Al–4%V. J. Mater. Process. Technol. 166, 188–192 (2005)

Choudhury, I.A., El-Baradie, M.A.: Surface roughness in the turning of high-strength steel by factorial design of experiments. J. Mater. Process. Technol. 67, 55–61 (1997)

Conforto, E., Arosson, B.O., Salito, A., Crestou, C., Caillard, D.: Rough surfaces of titanium alloys for implants and prostheses. Mater. Sci. Eng. 24(5), 611–618 (2004)

DeGarmo, E.P., Black, J.T., Kohser, R.A.: Materials and Processes in Manufacturing, 9th edn. Wiley, Hoboken (2003)

Escamilla, I., Torres, L., Perez, P., Zambrano, A.: Comparison between back propagation and the maximum sensibility neural network to surface roughness prediction in machining of titanium (Ti6Al4V) alloy. Lect. Notes Comput. Sci. 5317, 1009–1019 (2008)

Feng, C.-X., Wang, X.-F.: Surface roughness predictive modeling: neural networks versus regression. IIE Trans. 35, 11–27 (2003)

Ginta, T.L., Amin, A.N., Radzi, M., Lajis, M.A.: Development of surface roughness models in end milling titanium alloy Ti-6Al-4V using uncoated tungsten carbide inserts. Eur. J. Scientific Res. 28(4), 542–551 (2009)

Heretis, N.: A study on surface roughness and machining characteristics of Ti6Al4V alloy. Master’s thesis, Technical University of Crete, Greece (2003)

Heretis, N., Spanoudakis, P., Tsourveloudis, N.: Surface roughness characteristics of the Ti6Al4V alloy in Conventional Lathe and Mill Machining. Int. J. Surf. Sci. Eng. 3(5/6), 435–447 (2009)

Jang, J.S.R.: ANFIS: adaptive-network- based fuzzy inference system. IEEE Trans. Syst. Man Cybern. 23, 665–685 (1993)

Jang, J.S.R., Sun, C.-T., Mizutani, E.: Neuro-fuzzy and Soft Computing: A Computational Approach to Learning and Machine Intelligence. Prentice-Hall, New York (1997)

Kwak, J.-S.: Application of Taguchi and response surface methodologies for geometric error in surface grinding process. Int. J. Mach. Tools Manuf. 45, 327–334 (2005)

Modgil, A.: Effects of high speed machining on surface topography of titanium alloy (TI6AL4V). MSc thesis, University of Florida, Gainesville, USA (2003)

Myers, R.H., Montgomery, D.C.: Response surface methodology, process and product optimization using designed experiments. Wiley, New York (1995)

Ramesh, S., Karunamoorhty, L., Palanikumar, K.: Surface roughness analysis in machining of titanium alloy. Mater. Manuf. Process. 23, 174–180 (2008)

Ross, P.J.: Taguchi Techniques for Quality Engineering: Loss Function, Orthogonal Experiments, Parameter and Tolerance Design. McGraw-Hill, New York (1996)

Schey, J.A.: Introduction to Manufacturing Processes, 3rd edn. McGraw Hill, New York (2000)

Sidda Reddy, B., Kumar, J.S., Vijaya Kumar Reddy, K.: Prediction of surface roughness in turning using adaptive neuro-fuzzy inference system. Jordan J. Mech. Ind. Eng. 3(4), 252–259 (2009)

Suresh, P.V.S., Venkateswara, R.P., Deshmukh, S.G.: A genetic algorithmic approach for optimization of surface roughness prediction model. Int. J. Mach. Tools Manuf. 42, 675–680 (2002)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tsourveloudis, N.C. Predictive Modeling of the Ti6Al4V Alloy Surface Roughness. J Intell Robot Syst 60, 513–530 (2010). https://doi.org/10.1007/s10846-010-9427-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10846-010-9427-6