Abstract

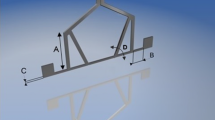

This paper presents a new design of multi micro manipulation system using ionic polymer metal composite (IPMC) micro grippers for robotic micro assembly where IPMC is used as a light weight actuator for developing the micro grippers. It has the potential of large displacement, low mass force generation and misalignment compensation ability during micro manipulation. These capabilities are utilized for handling of miniature parts like pegs. The analysis of IPMC micro gripper and manipulator are carried out for developing a multi micro manipulation system that can handle pegs in micro assembly operation for shifting one to another hole position in a large work space (100 mm × 100 mm). By developing a prototype, it is demonstrated that IPMC based micro grippers are capable of handling the peg-in-hole assembly tasks in a multi micro manipulation system.

Similar content being viewed by others

References

Tanikawa, T., Arai, T.: Development of a micro-manipulation system having a two-fingered micro-hand. IEEE Trans. Robot. Autom. 15(1), 152–162 (1999)

Yim, M., et al.: Modular self-reconfigurable robot systems challenges and opportunities for the future. IEEE Robot. Autom. Mag. 14(1), 43–52 (2007)

Scholz-Reiter, B., Freitag, M.: Autonomous processes in assembly systems. CIRP Ann. 56(2), 712–729 (2007)

Burisch, A., Wrege, J., Raatz, A., Hesselbach, J., Degen, R.: PARVUS-miniaturized robot for improved flexibility in micro production. J. Assem. Autom. 27(1), 65–73 (2007)

Ouyang, P.R., Tjiptoprodjo, R.C., Zhang, W.J., Yang, G.S.: Micro-motion devices technology: the state of arts review. Int. J. Adv. Manuf. Technol. 38, 463–478 (2008)

Troisfontaine, N., Bidaud, P., Morel, G.: A new inter-phalangeal actuator for dexterous micro-grippers. In: IEEE International Conference on Robotics and Automation, pp. 1773–1778. Albuquerque, New Mexico (1997)

Causey, G.: Guidelines for the design of robotic gripping systems. Assem. Autom. 23(1), 18–28 (2003)

Molfino, R., Razzoli, R.P., Zoppi, M.: A low-cost reconfigurable gripper for assembly and disassembly tasks in white industry. In: 8th International IFAC Symposium on Robot Control, vol. 8, no. 1, pp. 498–505. Santa Cristina, Convent, Italy (2006)

Dechev, N., Cleghorn, W.L., Mills, J.K.: Microassembly of 3-D microstructures using a compliant, passive micro gripper. J. Microelectromech. Syst. 13(2), 176–189 (2004)

Huang, J., Fukuda, T., Matsuno, T.: Model-based intelligent fault detection and diagnosis for mating electric connectors in robotic wiring harness assembly systems. IEEE/ASME Trans. Mechatron. 13(1), 86–94 (2008)

Huang, J., Di, P., Fukuda, T., Matsuno, T.: Robust model-based online fault detection for mating process of electric connectors in robotic wiring harness assembly systems. IEEE Trans. Control Syst. Technol. 18(5), 1207–1215 (2010)

Havlík, Š.: Passive compliant mechanisms for robotic (micro) devices. In: 13th World Congress in Mechanism and Machine Science, Guanajuato, México (Paper No A12_273) pp. 1–7, 19–25 June 2011

Lumia, R., Shahinpoor, M.: IPMC micro gripper research and development. J. Phys. 127, 1–15 (2008)

Deole, U., Lumia, R., Shahinpoor, M., Bermudez M.: Design and test of IPMC artificial muscle micro gripper. J. Micro Nano Mechatron. 4(3), 95–102 (2008)

Lumia, R.: A micro robotic gripper and force sensor. In: Goal, F.L., Nguyen, Q.V. (eds.) Advances in Intelligent and Soft Computing. Proceedings of the 2011 2nd International Congress on Computer Applications and Computational Science, vol. 144, pp. 1–8 (2012)

Jain, R.K., Patkar, U.S., Majumder, S.: Micro gripper for micro manipulation using ionic polymer metal composite. J. Sci. Ind. Res. 68, 23–28 (2009)

Jain, R.K., Datta, S., Majumder, S., Dutta, A.: Two IPMC fingers based micro gripper for handling. Int. J. Adv. Robot. Syst. 8(1), 1–9 (2011)

Jain, R.K., Majumder, S., Dutta, A.: Micro assembly by an IPMC based flexible 4-bar mechanism. Smart Mater. Struct. 21(7) (2012). doi:10.1088/0964-1726/21/7/075004

Carrozza, C.M., Eisinberg, A., Menciassi, A., Campolo, D., Micera S., Dario, P.: Towards a force-controlled micro gripper for assembling biomedical micro devices. J. Micro Mech. Micro Eng. 10, 271–276 (2000)

Petrovic, D., Chatzitheodoridis, E., Popovic, G., Medico, O.D., Almansa, A., Brenner, W., Detter, H., Martins, R., Fortunato, E.: Design of a mechanical gripper for assembly of micro parts. Convegno Nazionale AIAS—Alghero (SS) 1369–1373 (2001)

Nguyen, N.T., Ho, S.S., Low, C.L.N.: A polymeric micro gripper with integrated thermal actuators. J. Micro Mech. Micro Eng. 14, 969–974 (2004)

Kim, D.H., Lee, M.G., Kim, B., Sun, Y.: A super elastic alloy micro gripper with embedded electromagnetic actuators and piezoelectric force sensors: a numerical and experimental study. Smart Mater. Struct. 14, 1265–1272 (2005)

Hsu, T.R.: Micro assembly—a technology on the frontier of new industrial automation. In: 8th International Conference on Automation Technology, Taichung, Taiwan, 5–6 May 2005

Filippo, M., Rezia, M., Cepolina, F.: Miniature gripping device. In: Proc. of IEEE International Conference on Intelligent Manipulation and Grasping (IMG 04), Genova, Italy, 1–2 July 2004

Cl‘evy, C., Hubert, A., Chaillet, N.: Flexible micro-assembly system equipped with an automated tool changer. J. Micro Nano Mechatron. 4(1), 59–72 (2008)

Rabenorosoa, K., Haddab, Y., Lutz, P.: A low cost coarse/fine piezo electrically actuated micro gripper with force measurement adapted to eupass control structure. In: Ratchev, S., Koelemeijer, S. (eds.) IFIP International Federation for Information Processing, Micro-Assembly Technologies and Applications, vol. 260, pp. 235–242. Springer, Boston (2008)

Rabenorosoa, K., Das, A.N., Murthy, R., Cl’evy, C., Popa, D., Lutz, P.: Precise motion control of a piezo electric micro gripper for micro spectrometer assembly. In: ASME’09 International Design Engineering Technical Conferences (IDETC’09) & Computers and Information in Engineering Conference (CIE’09). San Diego, CA, USA (2009)

Ye, X., Zhang, Z.: Piezoelectric-ceramic-based micro grippers in micromanipulation. In: Suaste-Gomez, E. (ed.) Chapter 13 in Piezoelectric Ceramics, ISBN 978-953-307-122-0, pp. 253–268, 5 Oct 2010

Rakotondrabe, M., Ivan, I.A.: Development and force/ position control of a new hybrid thermo-piezoelectric micro gripper dedicated to micromanipulation tasks. IEEE Trans. Autom. Sci. Eng. (T-ASE) 8(4), 824–834 (2011)

Ivan, I.A., Rakotondrabe, M., Lutz, P., Chaillet, N.: Self-sensing measurement in piezoelectric cantilevered actuators for micromanipulation and micro assembly contexts. In: Cl’evy, C., et al. (eds.) Signal Measurement and Estimation Techniques for Micro and Nanotechnology, pp. 29–69 (2011). doi:10.1007/978-1-4419-9946-72

Causey, G.C., Quinn, R.D.: Gripper design guidelines for modular manufacturing. In: Proceedings of the 1998 IEEE International Conference on Robotics and Automation CAISR Tech Report, TR97-109 (1998)

Brussel, H.V., Peirs, J., Reynaerts, D., Delchambre, A., Reinhart, G., Roth, N., Weck, M., Zussman, E.: Assembly of microsystems. CIRP Ann. 49(2), 451–472 (2000)

Edmondson, N.F., Redford, A.H.: A compliance device for flexible close tolerance assembly. Ind. Robot Int. J. 28(1), 54–62 (2000)

Kim, J.Y., Cho, H.S.: A neural net-based assembly algorithm for flexible parts assembly. J. Intell. Robot. Syst. 29, 133–160 (2000)

Fei, Y., Zhao, X.: An assembly process modeling and analysis for robotic multiple peg-in-hole. J. Intell. Robot. Syst. 36, 175–189 (2003)

Dechev, N., Cleghorn, W.L., Mills, J.K.: Construction of a 3D MEMS micro coil using sequential robotic micro assembly operations. In: Proceedings of ASME IMECE 2003: 2003 ASME International Mechanical Engineering Congress and R&D Expo, Washington, D.C., 15–21 Nov 2003

Dechev, N., Ren, L., Liu, W., Cleghorn, W.L., Mills, J.K.: Development of a 6 degree of freedom robotic micromanipulator for use in 3D MEMS micro assembly. In: Proceedings of the 2006 IEEE International Conference on Robotics and Automation, Orlando, Florida, pp. 281–288, 15–19 May 2006

Chu, H.K., Mills, J.K., Cleghorn, W.L.: Automated parallel micro assembly for MEMS application. J. Micromech. Microeng. 22, 035017 (9pp) (2012)

Kratochvil, B.E., Yes, K.B., Hess, V., Nelson, B.J.: Design of a visually guided 6 DOF micromanipulator system for 3D assembly of hybrid MEMS. In: Proceedings of the 4th International Workshop on Microfactories (2004)

Probst, M., Borer, R., Nelson, B.J.: A micro assembly system for manufacturing hybrid MEMS. In: 12th IFToMM World Congress, Besanc, 18–21 June 2007

Yang, G., Gaines, J.A., Nelson B.J.: A supervisory wafer-level 3D microassembly system for hybrid MEMS fabrication. J. Intell. Robot. Syst. 37, 43–68 (2003)

Gorman, J.J., Dagalakis, N.G.: Probe-based micro-scale manipulation and assembly using force feedback. In: 1st Joint Emer. Prep. & Response/Robotic & Remote Sys. Top. Mtg., Salt Lake City, UT, pp. 621–628 (2006)

Lu, Z., Chen, C.P.Y., Lin, W.: Force sensing and control in micromanipulation. IEEE Trans. Syst. Man Cybern.—Part C: Appl. Rev. 36(6), 713–724 (2006)

Hötzendorfera, H., Giouroudi, I., Brenner, W.: A force feedback system for micromanipulation with stereoscopic imaging. In: 32nd International Conference Micro and Nano-Engineering, Barcelona, Spain, 17–20 Sept 2006

Sano, T., Yamamoto, H.: Multi agent micromanipulation system. In: IEEE IST 2005 International Workshop on Imaging Systems and Techniques, Niagara Falls, Sheraton Hotel on the Falls, pp. 75–78, 13–14 May 2005

Buerkle, A., Fatikow, S.: Laser measuring system for a flexible micro robot-based micromanipulation station. In: Proceedings of the 2000 IEEE/RSJ International Conference on Intelligent Robots and Systems, Takamatsu, Japan, pp. 799–804, 31 Oct–05 Nov 2000

Bilen, H., Unel, M.: Micromanipulation using a micro assembly workstation with vision and force sensing. In: Proceedings of the 4th International Conference on Intelligent Computing: Advanced Intelligent Computing Theories and Applications—with Aspects of Theoretical and Methodological Issues, Shanghai, China, pp. 1164–1172, 15–18 Sept 2008

Hoover, A.M., Fearing, R.S.: Rapidly prototyped orthotweezers for automated micro assembly. In: IEEE International Conference on Robotics and Automation (ICRA), Roma, Italy, pp. 812–819, 10–14 April 2007

Popa, D.O., Murthy, R., Das, A.N.: M3-deterministic, multiscale, multirobot platform for microsystems packaging: design and quasi-static precision evaluation. IEEE Trans. Autom. Sci. Eng. (T-ASE) 6(2), 345–361 (2009)

Boudaoud, M., Haddab, Y., Le Gorrec, Y., Lutz, P.: Noise characterization in millimeter sized micromanipulation systems. Int. J. Mechatron. 21(6), 1087–1097 (2011)

Zareinejad, M., Rezaei, S.M., Ghidary, S.S., Abdullah, A.: Precision control of a piezo-actuated micro tele manipulation system. Int. J. Precis. Eng. Manuf. 1, 1–10 (2010). doi:10.1007/s12541-010-0007-2

Zhang, Y.L., Han, M.L., Yu, M.Y., Shee, C.Y., Ang, W.T.: Automatic hysteresis modeling of piezoelectric micromanipulator in vision-guided micromanipulation systems. IEEE/ASME Trans. Mechatron. 17(3), 547–553 (2012)

Tamadazte, B., Le-Fort Piat, N., Demb‘el‘e, S.: Robotic micromanipulation and micro assembly using mono-view and multi-scale visual servoing. IEEE/ASME Trans. Mechatron. 16(2), 277–287 (2011)

Tamadazte, B., Paindavoine, M., Agnus, J., Pétrini, V., Le-Fort Piat, N.: Four DOF piezoelectric micro gripper equipped with a smart CMOS camera. IEEE J. Micro Electro Mech. Syst. 21(2), 256–258 (2012)

Craig, J.J.: Introduction to Robotics: Mechanics and Control. Pearson Education Inc, Delhi (2005)

Shahinpoor, M., Kim K.J.: Ionic polymer–metal composites: I. Fundamental. Smart Mater. Struct. 10, 819–833 (2001)

Howell, L.L.: Compliant Mechanisms. Brigham Young University, Wiley (2001)

Paquette, J.W., Kim, K.J., Kim, D.: Low temperature characteristics of ionic polymer–metal composite actuators. Sensors Actuators A 118, 135–143 (2005)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jain, R.K., Datta, S., Majumder, S. et al. Development of Multi Micro Manipulation System Using IPMC Micro Grippers. J Intell Robot Syst 74, 547–569 (2014). https://doi.org/10.1007/s10846-013-9874-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10846-013-9874-y