Abstract

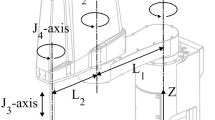

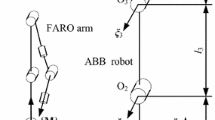

This paper is focused on the development and validation of an error kinematic model of a mini spherical robot, aimed at its kinematic calibration. The robot is actually a spatial five-bar linkage, provided with two rotational degrees of freedom. A non-overconstrained kinematics is assumed for the robot in order to provide a simple mathematical model and allow a sensitivity analysis of all the involved geometric parameters. A simplified version of the model is proposed. It differs only for the degree of approximation. A comparison between full and reduced models is presented by means of numerical simulations, analyzing their behavior in a significant region of the robot workspace. In order to validate both of them a robot calibration is carried out on a physical prototype of the robot using a vision system, namely a fixed camera in a eye-to-hand configuration. An iterative algorithm aimed at the experimental identification of the geometric data of the robot is used. Some experimental results show the effectiveness of the study.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.References

Abtahi, M., Pendar, H., Alasty, A., Vossoughi, G.: Experimental kinematic calibration of parallel manipulators using a relative position error measurement system. Robot. Comput. Integr. Manuf. 26(6), 799–804 (2010)

Fassi, I., Legnani, G.: Hand to sensor calibration: A geometrical interpretation of the matrix equation AX=XB. J. Robot. Syst. 22(9), 497–506 (2005)

Gojtan, G., Furtado, G., Hess-Coelho, T.: Error analysis of a 3-dof parallel mechanism for milling applications. ASME J. Mech. Robot 5(3), 034,501 (9 pages) (2013)

Gonzalez-Hernandez, A., Castillo-Castaneda, E.: Stiffness estimation of a parallel manipulator using image analysis and camera calibration techniques. Robotica 31(4), 657–667 (2013)

Gosselin, C., Caron, F.: Two degree-of-freedom spherical orienting device. Google Patents, https://www.google.ch/patents/US5966991. US Patent n∘5,966,991 (1999)

Heikkila, J., Silven, O.: A four-step camera calibration procedure with implicit image correction. In: Proceedings of IEEE Computer Society Conference on Computer Vision and Pattern Recognition, pp. 1106–1112. San Juan, Puerto Rico (1997)

Hollerbach, J.M., Wampler, C.W.: The calibration index and taxonomy for robot kinematic calibration methods. Int. J. Robot. Res. 15(6), 573–591 (1996)

Huang, T., Chetwynd, D.G., Mei, J.P., Zhao, X.M.: Tolerance design of a 2-dof overconstrained translational parallel robot. IEEE Trans. Robot. 22(1), 167–172 (2006)

Jin, Y., Chen, I.M.: Effects of constraint errors on parallel manipulators with decoupled motion. Mech. Mach. Theory 41(8), 912–928 (2006)

Kim, H.: Kinematic calibration of a cartesian parallel manipulator. Int. J. Control Autom. Syst. 3(3), 453–460 (2005)

Legnani, G., Tosi, D., Adamini, R., Fassi, I.: Calibration of parallel kinematic machines: theory and applications, industrial robotics: programming, simulation and applications. In: Huat, L.K. (ed.) InTech (2006)

Liu, H., Huang, T., Chetwynd, D.G.: A general approach for geometric error modeling of lower mobility parallel manipulators. J. Mech. Robot. 3(2), 0210,131 (13 page) (2011)

Meng, J., Li, Z.: A general approach for accuracy analysis of parallel manipulators with joint clearance. In: 2005 IEEE/RSJ International Conference on Intelligent Robots and Systems, pp. 2468–2473. Edmonton, Alberta (2005)

Merlet, J.P.: Interval analysis for certified numerical solution of problems in robotics. Int. J. Appl. Math. Comput. Sci. 19, 399–412 (2009)

Mooring, B., Roth, Z.S., Driels, M.R.: Fundamentals of Manipulator Calibration. Wiley, New York (1991)

Palmieri, G.: On the positioning error of a 2-dof spherical parallel wrist with flexible links and joints - an fem approach. Mech. Sci. 6, 9–14 (2015)

Palmieri, G., Callegari, M., Carbonari, L., Palpacelli, M.C.: Mechanical design of a mini pointing device for a robotic assembly cell. Meccanica 50(7), 1895–1908 (2015)

Palpacelli, M.C., Palmieri, G., Carbonari, L., Corinaldi, D.: Sensitivity analysis of a mini pointing device. In: Proceedings of MESA 2016 - 12th IEEE/ASME International Conference on Mechatronic and Embedded Systems and Applications. Auckland, New Zealand (2016)

Park, F.C., Okamura, K.: Kinematic Calibration and the Product of Exponentials Formula, pp. 119–128. Springer, Dordrecht (1994)

Pashkevich, A., Chablat, D., Wenger, P.: Stiffness analysis of overconstrained parallel manipulators. Mech. Mach. Theory 44(5), 966–982 (2009)

Ramesh, R., Mannan, M., Poo, A.: Error compensation in machine tools a review: part i: geometric, cutting-force induced and fixture-dependent errors. Int. J. Mach. Tools Manuf. 40(9), 1235–1256 (2000)

Rao, S., Bhatti, P.: Probabilistic approach to manipulator kinematics and dynamics. Reliab. Eng. Syst. Safety 72(1), 47–58 (2001)

Rauf, A., Kim, S.G., Ryu, J.: Complete parameter identification of parallel manipulators with partial pose information using a new measurement device. Robotica 22(6), 689–695 (2004)

Renaud, P., Andreff, N., Martinet, P., Gogu, G.: Kinematic calibration of parallel mechanisms: A novel approach using legs observation. IEEE Trans. Robot. 21(4), 529–538 (2005)

Sun, T., Zhai, Y., Song, Y., Zhang, J.: Kinematic calibration of a 3-dof rotational parallel manipulator using laser tracker. Robot. Comput.-Integr. Manuf. 41, 78–91 (2016)

Tannous, M., Caro, S., Goldsztejn, A.: Sensitivity analysis of parallel manipulators using an interval linearization method. Mech. Mach. Theory 71, 93–114 (2014)

Traslosheros, A., Sebastián, J.M., Torrijos, J., Carelli, R., Castillo, E.: An inexpensive method for kinematic calibration of a parallel robot by using one hand-held camera as main sensor. Sensors 13, 9941–9965 (2013)

Vivas, A., Poignet, P., Marquet, F., Pierrot, F., Gautier, M.: Experimental dynamic identification of a fully parallel robot. In: 2003 IEEE International Conference on Robotics and Automation (Cat. No.03CH37422), vol. 3, pp. 3278–3283. Taipei, Taiwan (2003)

Wang, S., Ehmann, K.: Error model and accuracy analysis of a six-dof stewart platform. ASME J. Manuf. Sci. Eng. 124(2), 286–295 (2002)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Palpacelli, M., Palmieri, G., Carbonari, L. et al. Sensitivity Analysis and Model Validation of a 2-DoF Mini Spherical Robot. J Intell Robot Syst 91, 155–163 (2018). https://doi.org/10.1007/s10846-017-0679-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10846-017-0679-2