Abstract

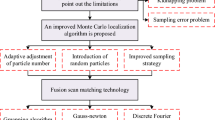

Achieving high-precision manufacturing of optical components requires improving the absolute positioning accuracy of the robot to the highest possible level. Identifying the robot's kinematic parameters and compensating for kinematic errors are effective methods for improving the robot's positioning accuracy. This paper proposes a hybrid algorithm that combines the Levenberg–Marquardt algorithm and an opposition-based learning squirrel search algorithm to identify the kinematic parameters of a polishing robot. Firstly, the Levenberg–Marquardt algorithm is utilized to solve the suboptimal values of kinematic parameter deviations. Secondly, an opposition-based learning strategy is integrated into the standard squirrel search algorithm to increase the diversity of the population and prevent the population from getting stuck in local optima. The suboptimal values obtained by the Levenberg–Marquardt algorithm are subsequently used as the central values to generate the initial population for the opposition-based learning squirrel search algorithm, which helps identify more accurate kinematic parameter deviations. Ultimately, the kinematic parameters of the robot are effectively calibration. The calibration experimental results showed that the proposed method achieved a high level of calibration accuracy, resulting in a 62.61% improvement in absolute positioning error compared to before calibration. Offline machining experiments have validated the effectiveness of LM-OBLSSA in reducing deviations in the dwell points of optical components during the machining process.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Data Availability

Data underlying the results presented in this paper are not publicly available at this time but may be obtained from the authors upon reasonable request.

Code Availability

Not applicable.

References

Zhu, D., Feng, X., Xu, X., Yang, Z., Li, W., Yan, S., Ding, H.: Robotic grinding of complex components: A step towards efficient and intelligent machining – challenges, solutions, and applications. Robot. Comput. Integr. Manuf. 65, 101908–101923 (2020)

Lin, F., Lu, T.: Development of a robot system for complex surfaces polishing based on CL data. Int. J. Adv. Manuf. Technol. 26, 1132–1137 (2004)

Yuan, L., Pan, Z., Ding, D., Sun, S., Li, W.: A Review on Chatter in Robotic Machining Process Regarding Both Regenerative and Mode Coupling Mechanism. IEEE/ASME Trans. Mechatron. 23, 2240–2251 (2018)

Wang, W., Liu, F., Yun, C.: Calibration method of robot base frame using unit quaternion form. Precis. Eng. 41, 47–54 (2015)

Li, Z., Li, S., Luo, X.: An overview of calibration technology of industrial robots. IEEE/CAA J. Autom. Sin. 8, 23–36 (2021)

Zhang, T., Song, Y., Wu, H., Wang, Q.: A novel method to identify DH parameters of the rigid serial-link robot based on a geometry model. Ind. Robot Int. J. Robot. Res. Appl. 48, 157–167 (2020)

Mao, C., Chen, Z., Li, S., Zhang, X.: Separable Nonlinear Least Squares Algorithm for Robust Kinematic Calibration of Serial Robots. J. Intell. Robot. Syst. 101, 2 (2021)

Jiang, Z., Gao, W., Yu, X.: An improved robot calibration method using the modified adjoint error model based on POE. Adv. Robot. 34, 1229–1238 (2020)

Wu, Y., Klimchik, A., Caro, S., Furet, B., Pashkevich, A.: Kinematic calibration of industrial robots using enhanced partial pose measurements and design of experiments. Robot. Comput. Integr. Manuf. 35, 151–168 (2015)

Kim, S., Nam, E., Ha, T., Hwang, S., Lee, J., Park, S., Min, B.: Robotic Machining: A Review of Recent Progress. Int. J. Precis. Eng. Manuf. 20, 1629–1642 (2019)

He, S., Ma, L., Yan, C., Lee, C., Hu, P.: Multiple location constraints based industrial robot kinematic parameter calibration and accuracy assessment. Int. J. Adv. Manuf. Technol. 102, 1037–1050 (2018)

Lattanzi, L., Cristalli, C., Massa, D., Boria, S., Lépine, P., Pellicciari, M.: Kinematical calibration of a 6-axis robotic arm for high accuracy manufacturing task. Int. J. Adv. Manuf. Technol. 111, 1813–1829 (2020)

Luo, G., Zou, L., Wang, Z., Lv, C., Ou, J., Huang, Y.: A novel kinematic parameters calibration method for industrial robot based on Levenberg-Marquardt and Differential Evolution hybrid algorithm. Robot. Comput. Integr. Manuf. 71. https://doi.org/10.1016/j.rcim.2021.102165(2021)

Jiang, Z., Zhou, W., Li, H., Mo, Y., Ni, W., Huang, Q.: A New Kind of Accurate Calibration Method for Robotic Kinematic Parameters Based on the Extended Kalman and Particle Filter Algorithm. IEEE Trans. Industr. Electron. 65, 3337–3345 (2018)

Chen, X., Zhan, Q.: The Kinematic Calibration of a Drilling Robot with Optimal Measurement Configurations Based on an Improved Multi-objective PSO Algorithm. Int. J. Precis. Eng. Manuf. 22, 1537–1549 (2021)

Wang, W., Song, H., Yan, Z., Sun, L., Du, Z.: A universal index and an improved PSO algorithm for optimal pose selection in kinematic calibration of a novel surgical robot. Robot. Comput. Integr. Manuf. 50, 90–101 (2018)

Nguyen, H., Cao, H., Nguyen, T., Tran, T., Tran, H., Jeon, J.: Improving Robot Precision Positioning Using a Neural Network Based on Levenberg Marquardt–APSO Algorithm. IEEE Access 9, 75415–75425 (2021)

Li, Z., Li, S., Bamasag, O., Alhothali, A., Luo, X.: Diversified Regularization Enhanced Training for Effective Manipulator Calibration. IEEE Trans. Neural Netw. Learn. Syst. https://doi.org/10.1109/TNNLS.2022.3153039(2022)

Gan, Y., Duan, J., Dai, X.: A calibration method of robot kinematic parameters by drawstring displacement sensor. Int. J. Adv. Rob. Syst. 16, 1–9 (2019)

Qin, Y., Geng, P., Lv, B., Meng, Y., Song, Z., Han, J.: Simultaneous Calibration of the Hand-Eye, Flange-Tool and Robot-Robot Relationship in Dual-Robot Collaboration Systems. Sensors (Basel) 22, 1861 (2022)

Liu, K., Xia, J., Zhong, F., Zhang, L.: Structural parameters identification for industrial robot using a hybrid algorithm. Int. J. Adv. Rob. Syst. 19, 1–15 (2022)

Fan, J.: A Shamanskii-like Levenberg-Marquardt method for nonlinear equations. Comput. Optim. Appl. 56, 63–80 (2013)

Wilamowski, B., Yu, H.: Improved computation for Levenberg-Marquardt training. IEEE Trans. Neural Netw. 21, 930–937 (2010)

Fan, J., Huang, J., Pan, J.: An Adaptive Multi-step Levenberg–Marquardt Method. J. Sci. Comput. 78, 531–548 (2018)

Jain, M., Singh, V., Rani, A.: A novel nature-inspired algorithm for optimization: Squirrel search algorithm. Swarm Evol. Comput. 44, 148–175 (2019)

Zhang, X., Zhao, K., Wang, L., Wang, Y., Niu, Y.: An Improved Squirrel Search Algorithm With Reproductive Behavior. IEEE Access 8, 101118–101132 (2020)

Lenin, K.: Real power loss reduction by Duponchelia fovealis optimization and enriched squirrel search optimization algorithms. Soft. Comput. 24, 17863–17873 (2020)

Sakthivel, V., Suman, M., Sathya, P.: Combined economic and emission power dispatch problems through multi-objective squirrel search algorithm. Appl. Soft Comput. 100, 106950 (2021)

Zheng, T., Luo, W.: An Improved Squirrel Search Algorithm for Optimization. Complexity 2019, 1–31 (2019)

Tizhoosh, H.: Opposition-Based Learning: A New Scheme for Machine Intelligence. International Conference on Computational Intelligence for Modelling, Control and Automation and International Conference on Intelligent Agents, Web Technologies and Internet Commerce (CIMCA-IAWTIC’06), Vienna, Austria, 695–701 (2005)

Mahdavi, S., Rahnamayan, S., Deb, K.: Opposition based learning: A literature review. Swarm Evol. Comput. 39, 1–23 (2018)

Mohapatra, S., Mohapatra, P.:Fast random opposition-based learning Golden Jackal Optimization algorithm. Knowledge-Based Systems. 275, 110679 (2023). https://doi.org/10.1016/j.knosys.2023.110679

Li, Q., He, Q., Liu, Z.: Low NOx combustion optimization based on partial dimension opposition-based learning particle swarm optimization. Fuel. 310,122352 (2022). https://doi.org/10.1016/j.fuel.2021.122352

Deng, Y., Hou, X., Li, B., Wang, J., Zhang, Y.: A highly powerful calibration method for robotic smoothing system calibration via using adaptive residual extended Kalman filter. Robot. Comput. Integr. Manuf. 86, 102660 (2024)

Huang, B., Ma, C.: A Shamanskii-like self-adaptive Levenberg–Marquardt method for nonlinear equations. Comput. Math. Appl. 77, 357–373 (2019)

Zhang, J., Wang, X., Wen, K., Zhou, Y., Yue, Y., Yang, J.: A simple and rapid calibration methodology for industrial robot based on kinematic constraint and two-step error. Ind. Robot Int. J. 45, 715–721 (2018)

Cai, Y.,·Yuan, P., Shi,·Z., Chen, D., Cao, S.: Application of Universal Kriging for Calibrating Offline-Programming Industrial Robots. J. Intell. Robot. Syst. 94, 339–348 (2019)

Li, G., Xiao, F., Zhang, X., Tao, B., Jiang, G.: An inverse kinematics method for robots after geometric parameters compensation. Mech. Mach. Theory 174, 104903 (2022)

Wu, Y., Klimchik, A., Caro, S., Furet, B., Pashkevich, A.: Geometric calibration of industrial robots using enhanced partial pose measurements and design of experiments. Robot. Comput. Integr. Manuf. 35, 151–168 (2015)

Deng, Y., Hou, X., Li, B., Wang, J., Zhang, Y.: Review on mid-spatial frequency error suppression in optical components manufacturing. Int. J. Adv. Manuf. Technol. 126(11–12), 4827–4847 (2023)

Deng, Y., Hou, X., Li, B., Wang, J., Zhang, Y.: A novel method for improving optical component smoothing quality in robotic smoothing systems by compensating path errors. Opt. Express 31(19), 30359–30378 (2023)

Acknowledgements

Special thanks to the technical staff in the laboratory for their support and provision of equipment. Their expertise and assistance were instrumental in the smooth execution of experiments and data analysis.

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Yonghong Deng performed material preparation, data collection, and analysis, and wrote the first draft of the manuscript. Jia Wang offered revision and valuable suggestions. Yun Zhang contributed to revision and provided some valuable suggestions. Bincheng Li provided guidance. Xi Hou provided guidance, and final revision. All authors commented on previous versions of the manuscript, and all authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Ethics Approval

Not applicable.

Consent to Participate

Not applicable.

Consent for Publication

Not applicable.

Conflict of Interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Deng, Y., Hou, X., Li, B. et al. A Novel Positioning Accuracy Improvement Method for Polishing Robot Based on Levenberg–Marquardt and Opposition-based Learning Squirrel Search Algorithm. J Intell Robot Syst 110, 8 (2024). https://doi.org/10.1007/s10846-023-02038-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10846-023-02038-3