Abstract

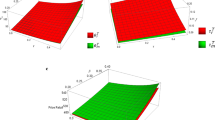

Based on the previous researches on closed-loop supply chain (CLSC), this paper takes the life cycle attributes of products into consideration and investigates the situation in which the manufacturer has a tendency to invest in green innovation and establish alliance with other supply chain members. In a two-cycle CLSC consisting of one manufacturer, one retailer and one-third party recycler, Stackelberg game method is adopted to analyze and compare the optimal decisions and profits of CLSC members as well as the efficiency of three green innovation alliance modes. The results show that the impact of difference among those three alliance modes on CLSC decision is obvious, and the operational efficiency of CLSC is always higher than that without alliance. From the perspective of consumers, environmental protection and profits, the green innovation alliance formed by manufacturer and retailer enjoys the lowest price, the highest green innovation level, the highest alliance profit and the relatively high level of resource recycling, which is the best choice for manufacturer. Finally, numerical examples are presented to obtain some conclusions and give some management inspirations intuitively. It is found that the coefficient of profit reduction in the second cycle has a significant impact on the decision-making and profits of the members and entire CLSC, but the positive influence of consumers’ sensitivity to the green innovation of manufacturer is not obvious.

Similar content being viewed by others

Abbreviations

- CLSC:

-

Closed-loop supply chain

- NA:

-

Non-alliance mode

- MR-A:

-

Alliance of manufacturer and retailer

- MT-A:

-

Alliance of manufacturer and third party

References

Alumur SA, Nickel S, Saldanha-da-Gama F, Verter V (2012) Multi-period reverse logistics network design. Eur J Oper Res 220:67–78

Dai R, Zhang JX, Tang WS (2017) Cartelization or cost-sharing? Comparison of cooperation modes in a green supply chain. J Clean Prod 156:159–173

Gao JH, Han HS, Hou LT, Wang HY (2016) Pricing and effort decisions in a closed-loop supply chain under different channel power structures. J Clean Prod 112:2043–2057

Genc TS, Giovanni PD (2017) Trade-in and save: a two-period closed-loop supply chain game with price and technology dependent returns. Int J Prod Econ 183:514–527

Genc TS, Giovanni PD (2018) Closed-loop supply chain games with innovation-led lean programs and sustainability. Int J Prod Econ. https://doi.org/10.1016/j.ijpe.2018.1005.1026

Ghosh D, Shah J (2012) A comparative analysis of greening policies across supply chain structures. Int J Prod Econ 135(2):568–583

Giovanni PD, Zaccour G (2014) A two-period game of a closed-loop supply chain. Eur J Oper Res 232(1):22–40

Gu XY, Ieromonachou P, Zhou L, Tseng ML (2018) Developing pricing strategy to optimise total profits in an electric vehicle battery closed loop supply chain. J Clean Prod 203:376–385

Hasanov P, Jaber MY, Tahirov N (2019) Four-level closed loop supply chain with remanufacturing. Appl Math Model 66:141–155

He QD, Wang NM, Yang Z, He ZW, Jiang B (2019) Competitive collection under channel inconvenience in closed-loop supply chain. Eur J Oper Res 275(1):155–166

Hong XP, Wang ZJ, Wang DZ, Zhang HG (2013) Decision models of closed-loop supply chain with remanufacturing under hybrid dual-channel collection. Int J Adv Manuf Technol 68:1851–1865

Huang M, Song M, Lee LH, Ching WK (2013) Analysis for strategy of closed-loop supply chain with dual recycling channel. Int J Prod Econ 144(2):510–520

Kleindorfer PR, Singhal K, Wassenhove LN (2005) Sustainable operations management. Prod Oper Manag 14(4):482–492

Liu LW, Wang ZJ, Xu L, Hong XP, Govindan K (2017) Collection effort and reverse channel choices in a closed-loop supply chain. J Clean Prod 144:492–500

Ma YY, Sia CL, Li Y, Zheng SY (2016) Sources of resources, alliance green management, and alliance performance in an emerging economy. J Clean Prod 139:319–327

Pei J, Pardalos PM, Liu XB, Fan WJ, Yang SL (2015) Serial batching scheduling of deteriorating jobs in a two-stage supply chain to minimize the makespan. Eur J Oper Res 244:13–25

Pei J, Darzic Z, Drazic M, Mladenovic N, Pardalos PM (2018) Continuous variable neighborhood search (C-VNS) for solving systems of nonlinear equations. INFORMS J Comput. https://doi.org/10.1287/ijoc.2018.0876

Pei J, Cheng BY, Liu XB, Pardalos PM, Kong M (2019a) Single-machine and parallel-machine serial-batching scheduling problems with position-based learning effect and linear setup time. Ann Oper Res 272(1–2):217–241

Pei J, Liu XB, Fan WJ, Pardalos PM, Lu SJ (2019b) A hybrid BA-VNS algorithm for coordinated serial-batching scheduling with deteriorating jobs, financial budget, and resource constraint in multiple manufacturers. Omega 82:55–69

Pei J, Wei JL, Liao BY, Liu XB, Pardalos PM (2019c) Two agent scheduling on bounded parallel batching machines with an aging effect of job position dependent. Ann Oper Res. https://doi.org/10.1007/s10479-019-03160-y

Reimann M, Xiong Y, Zhou Y (2019) Managing a closed-loop supply chain with process innovation for remanufacturing. Eur J Oper Res 276(2):510–518

Savaskan RC, Van Wassenhove LN (2006) Reverse channel design: the case of competing retailers. Manag Sci 52(1):1–14

Savaskan RC, Bhattacharya S, Van Wassenhove LN (2004) Closed-loop supply chain models with product remanufacturing. Manag Sci 50(2):239–252

Wadin J, Ahlgren K, Bengtsson L (2017) Joint business model innovation for sustainable transformation of industries—a large multinational utility in alliance with a small solar energy company. J Clean Prod 160:139–150

Wang WB, Ding JF, Sun H (2018) Reward-penalty mechanism for a two-period closed-loop supply chain. J Clean Prod 203:898–917

Wei J, Govindan K, Li YJ, Zhao J (2015) Pricing and collecting decisions in a closed-loop supply chain with symmetric and asymmetric information. Comput Oper Res 54:257–265

Xu L, Wang C (2018) Sustainable manufacturing in a closed-loop supply chain considering emission reduction and remanufacturing. Resour Conserv Recycl 131:297–304

Yang T, Fu C, Liu X, Pei J, Liu L, Pardalos PM (2018) Closed-loop supply chain inventory management with recovery information of reusable containers. J Combin Optim 35(1):266–292

Zhang P, Xiong Y, Xiong ZK, Yan W (2014) Designing contracts for a closed-loop supply chain under information asymmetry. Oper Res Lett 42(2):150–155

Zhang SG, Ding YJ, Liu B, Pan DA, Chang CC, Volinsky AA (2015) Challenges in legislation, recycling system and technical system of waste electrical and electronic equipment in China. Waste Manag 45:361–373

Zhen L, Sun QJ, Wang K, Zhang XT (2019) Facility location and scale optimisation in closed-loop supply chain. Int J Prod Res. https://doi.org/10.1080/00207543.2019.1587189

Acknowledgements

The research was supported by General Foundation of Chongqing Industry Polytechnic College No. GZY201734-YB.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ma, C., Huang, D. Research on the impact of green innovation alliance mode on decision-making of two-cycle closed-loop supply chain. J Comb Optim 39, 519–546 (2020). https://doi.org/10.1007/s10878-019-00496-w

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10878-019-00496-w