Abstract

This paper proposes a new problem by integrating the job shop scheduling, the part feeding, and the automated storage and retrieval problems. These three problems are intertwined and the performance of each of these problems influences and is influenced by the performance of the other problems. We consider a manufacturing environment composed of a set of machines (production system) connected by a transport system and a storage/retrieval system. Jobs are retrieved from storage and delivered to a load/unload area (LU) by the automated storage retrieval system. Then they are transported to and between the machines where their operations are processed on by the transport system. Once all operations of a job are processed, the job is taken back to the LU and then returned to the storage cell. We propose a mixed-integer linear programming (MILP) model that can be solved to optimality for small-sized instances. We also propose a hybrid simulated annealing (HSA) algorithm to find good quality solutions for larger instances. The HSA incorporates a late acceptance hill-climbing algorithm and a multistart strategy to promote both intensification and exploration while decreasing computational requirements. To compute the optimality gap of the HSA solutions, we derive a very fast lower bounding procedure. Computational experiments are conducted on two sets of instances that we also propose. The computational results show the effectiveness of the MILP on small-sized instances as well as the effectiveness, efficiency, and robustness of the HSA on medium and large-sized instances. Furthermore, the computational experiments clearly shown that importance of optimizing the three problems simultaneous. Finally, the importance and relevance of including the storage/retrieval activities are empirically demonstrated as ignoring them leads to wrong and misleading results.

Similar content being viewed by others

Data Availability

All the data sets are available at https://fastmanufacturingproject.wordpress.com/problem-instances/

Notes

In this section, and for the sake of simplicity, we will refer to operations, tasks, and activities as operations whenever we refer to machines, AGVs, and shuttles as resources.

All data pertaining to the benchmark instances as well as to the original problem instances (Bilge and Ulusoy 1995; Lawrence 1984) can be downloaded from https://fastmanufacturingproject.wordpress.com/problem-instances.

References

Alonso-Ayuso A, Tirado G, Udías Á (2013) On a selection and scheduling problem in automatic storage and retrieval warehouses. Int J Prod Res 51(17):5337–5353

Azadeh K, De Koster R, Roy D (2019) Robotized and automated warehouse systems: Review and recent developments. Transp Sci 53(4):917–945

Bilge Ü, Ulusoy G (1995) A time window approach to simultaneous scheduling of machines and material handling system in an FMS. Oper Res 43(6):1058–1070

Boysen N (2016) Stephan K A survey on single crane scheduling in automated storage/retrieval systems. Eur J Oper Res 254(3):691–704

Burke EK, Bykov Y (2017) The late acceptance hill-climbing heuristic. Eur J Oper Res 258(1):70–78

Chetty KOV, Reddy SM (2003) Genetic algorithms for studies on AS/RS integrated with machines. The International Journal of Advanced Manufacturing Technology 22(11–12):932–940

Fathi M, Rodríguez V, Fontes DBMM, Alvarez MJ (2016) A modified particle swarm optimisation algorithm to solve the part feeding problem at assembly lines. Int J Prod Res 54(3):878–893

Fontes DBMM, Homayouni SM (2019) Joint production and transportation scheduling in flexible manufacturing systems. J Global Optim 74(4):879–908

Gagliardi J-P, Renaud J (2012) Ruiz A Models for automated storage and retrieval systems: a literature review. Int J Prod Res 50(24):7110–7125

Gao Y, Yuan J (2019) Unbounded parallel-batch scheduling under agreeable release and processing to minimize total weighted number of tardy jobs. J Comb Optim 38(3):698–711

Gnanavelbabu A, Jerald J, Noorul Haq A, Asokan P (2009) Multi objective scheduling of jobs, AGVs and AS/RS in FMS using artificial immune system. In: Proceedings of National Conference on Emerging Trends in Engineering and Sciences, pp. 229–239

Gu J, Gu M, Lu X, Zhang Y (2018) Asymptotically optimal policy for stochastic job shop scheduling problem to minimize makespan. J Comb Optim 36(1):142–161

Ham A (2021) Transfer-robot task scheduling in job shop. Int J Prod Res 59(3):813–823

Homayouni SM, Fontes DBMM, Gonçalves JF (2020) A multistart biased random key genetic algorithm for the flexible job shop scheduling problem with transportation. International Transactions in Operational Research

Homayouni SM, Fontes DBMM (2021) Production and transport scheduling in flexible job shop manufacturing systems. J Global Optim 79(2):463–502

Jawahar N, Aravindan P, Ponnambalam SG (1998) Optimal random storage allocation for an AS/RS in an FMS. The International Journal of Advanced Manufacturing Technology 14(2):116–132

Jiang Y, Zhang Q, Hu J, Dong J, Ji M (2015) Single-server parallel-machine scheduling with loading and unloading times. J Comb Optim 30(2):201–213

Kazemi M, Asef-Vaziri A, Shojaei T, Amiri S (2021) A math-heuristic algorithm for concurrent assignment and sequence scheduling in multi-shuttle shared location automated storage and retrieval systems. Journal of Supply Chain and Operations Management 19(1):1

Kirkpatrick S, Gelatt DC, Vecchi MP (1983) Optimization by simulated annealing. Science 220(4598):671–680

Kuhpfahl J, Bierwirth C (2016) A study on local search neighborhoods for the job shop scheduling problem with total weighted tardiness objective. Computers & Operations Research 66:44–57

Kung Y, Kobayashi Y, Higashi T, Sugi M, Ota J (2014) Order scheduling of multiple stacker cranes on common rails in an automated storage/retrieval system. Int J Prod Res 52(4):1171–1187

Lawrence S (1984) Resouce constrained project scheduling: an experimental investigation of heuristic scheduling techniques (supplement). Carnegie-Mellon University, Graduate School of Industrial Administration

Li Z, Barenji AV, Jiang J, Zhong RY, Xu G (2020) A mechanism for scheduling multi robot intelligent warehouse system face with dynamic demand. J Intell Manuf 31(2):469–480

Li Y, Wang J, Liu Z (2021) A simple two-agent system for multi-objective flexible job-shop scheduling. Journal of Combinatorial Optimization, 1–23

Luo L, Zhao N, Lodewijks G (2021) Scheduling storage process of shuttle-based storage and retrieval systems based on reinforcement learning. Complex System Modeling and Simulation 1(2):131–144

Makino (2020) Crowning Achievement, automation helps Prince industries master global manufacturing. https://www.competitiveproduction.com/articles/crowning-achievement/(Accessed: 03.07.2020)

Randall M, McMahon G, Sugden S (2002) A simulated annealing approach to communication network design. J Comb Optim 6(1):55–65

Reddy BSP, Rao CSP (2006) A hybrid multi-objective ga for simultaneous scheduling of machines and agvs in fms. The International Journal of Advanced Manufacturing Technology 31(5–6):602–613

ReliablePlanet (2020) Mazda capitalizes on flexible manufacturing capabilities. https://www.reliableplant.com/Read/7750/mazda(Accessed: 03.07.2020)

Roodbergen KJ, Vis IF (2009) A survey of literature on automated storage and retrieval systems. Eur J Oper Res 194(2):343–362

Sekkal N, Belkaid F (2020) A multi-objective simulated annealing to solve an identical parallel machine scheduling problem with deterioration effect and resources consumption constraints. J Comb Optim 40(3):660–696

Song J, Yang M, Zhou X (2020) Scheduling optimization of automated storage and retrieval system based on four-way shuttles. In: 2020 IEEE International Conference on Mechatronics and Automation (ICMA), pp. 524–529 . IEEE

Tostani HH, Haleh H, Molana HSM, Sobhani FM (2020) A bi-level bi-objective optimization model for the integrated storage classes and dual shuttle cranes scheduling in AS/RS with energy consumption, workload balance and time windows. J Clean Prod 257:120409

Zhang J, Ding G, Zou Y, Qin S, Fu J (2019) Review of job shop scheduling research and its new perspectives under industry 4.0. J Intell Manuf 30(4):1809–1830

Zhang X, Lin W-C, Wu C-C (2021) Rescheduling problems with allowing for the unexpected new jobs arrival. Journal of Combinatorial Optimization, 1–16

Zhang S, Nip K, Wang Z (2020) Related machine scheduling with machine speeds satisfying linear constraints. Journal of Combinatorial Optimization, 1–17

Funding

This work is partially supported by the ERDF - European Regional Development Fund through the Operational Programme for Competitiveness and Internationalisation - COMPETE 2020 Programme and by National Funds through the Portuguese funding agency, FCT - Fundação para a Ciência e a Tecnologia within projects POCI-010145-FEDER-031821-PTDC/EGE-OGE/31821/2017 and POCI-010145-FEDER-031447-PTDC/EEI-AUT/31447/2017.

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors have no conflicts of interest to declare that are relevant to the content of this article.

Code available

All the programming codes are available upon request.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix A: Automated storage/retrieval system and shuttle travel times calculation

Appendix A: Automated storage/retrieval system and shuttle travel times calculation

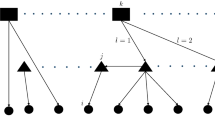

The ASRS considered has four rectangular racks each of which with \(m=10\) rows and \(n=10\) columns. The storage cells are numbered sequentially from 1 to \(nm=100\) in the first rack, from \(nm+1=101\) to \(2nm=200\) in the second rack, from \(2nm+1=201\) to \(3nm=300\) in the third rack, and from \(3nm+1=301\) to \(4nm=400\) in the fourth rack, as depicted in Fig. 9. Each pair of storage racks is serviced by a single shuttle that moves along the aisle between them.

ASRS illustration, adapted from (Jawahar et al. 1998)

Each job i is allocated to a storage cell \({SC}_i\). The specific storage cell can be easily identified as its row (\(x_i\)) and column (\(y_i\)) numbers can be obtained through a simple algebraic calculation, as given by Equation (A1), where q is the result of the integer division of \({SC}_i\) by n and r its remainder.

The shuttles travel at a constant speed (i.e., the shuttle has no acceleration or deceleration). The travel time \(TS_{i}^k\) between storage cells i and k is calculated by dividing the Chebyshev distance between the two storage cells by the shuttle speed, as shown in Equation (A2), where \(D_r\) and \(D_c\) are, respectively, row and column center distances between any two adjacent cells and the operator \(|\bullet |\) returns the absolute value. Similarly, the travel time \(TS_{i}\) between storage cell i and the LU, and vice versa, is obtained through Equation (A3), where C is a constant representing the time required to transfer a job between the shuttle and the LU.

The storage and retrieval cells allocated to each job as well as all other data can be found at https://fastmanufacturingproject.wordpress.com/problem-instances/.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Fontes, D.B.M.M., Homayouni, S.M. & Resende, M.G.C. Job-shop scheduling-joint consideration of production, transport, and storage/retrieval systems. J Comb Optim 44, 1284–1322 (2022). https://doi.org/10.1007/s10878-022-00885-8

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10878-022-00885-8