Abstract

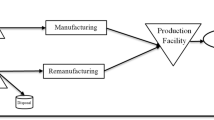

Hybrid manufacturing and remanufacturing systems have become a topic of considerable interest in the advanced manufacturing industry due in part to the profit and cost saving by reusing remaufacturable parts in the end-of-use products. In this paper, we investigate a production planning problem in such a hybrid system with the integration of resource capacity planning that is shared by both manufacturing and remanufacturing processes. Due to the uncertain nature in practice, both new and remanufactured product demands are stochastic. Taking a scenario-based approach to express the stochastic demands according to the historical data, we formulate the stochastic aggregate production planning problem as a mixed integer linear programming (MILP) model. Based on the Lagrangian relaxation (LR) technique, the MILP model is decomposed into four sets of sub-problems. For these sub-problems, four heuristic procedures are developed, respectively. Then, a LR based heuristic for the main problem is proposed and further tested on a large set of problem instances. The results show that the algorithm generates solutions very close to optimums in an acceptable time. At last, the impact of demands uncertainty on the solution is analyzed by the sensitivity analysis on a number of scenarios.

Similar content being viewed by others

References

Akcali, E., Cetinkaya, S.: Quantitative models for inventory and production planning in closed-loop supply chains. Int. J. Prod. Res. 49(8), 2373–2407 (2011)

Bertsekas, D.P.: Constrained Optimization and Lagrangian Multiplier Methods. Academic Press, New York (1982)

Chen, M., Abrishami, P.: A mathematical model for production planning in hybrid manufacturing–remanufacturing systems. Int. J. Adv. Manuf. Technol. 71(5–8), 1187–1196 (2014)

Chen, Z.L., Li, S.L., Tirupati, D.: A scenario-based stochastic programming approach for technology and capacity planning. Comput. Oper. Res. 29(7), 781–806 (2002)

Fleischmann, M., BloemhofRuwaard, J.M., Dekker, R., et al.: Quantitative models for reverse logistics: a review. Eur. J. Oper. Res. 103(1), 1–17 (1997)

Han, S.H., Dong, M.Y., Lu, S.X., et al.: Production planning for hybrid remanufacturing and manufacturing system with component recovery. J. Oper. Res. Soc. 64(10), 1447–1460 (2013)

Hsu, C.I., Li, H.C.: An integrated plant capacity and production planning model for high-tech manufacturing firms with economies of scale. Int. J. Prod. Econ. 118(2), 486–500 (2009)

Kaya, O., Bagci, F., Turkay, M.: Planning of capacity, production and inventory decisions in a generic reverse supply chain under uncertain demand and returns. Int. J. Prod. Res. 52(1), 270–282 (2014)

Kenne, J.P., Dejax, P., Gharbi, A.: Production planning of a hybrid manufacturing–remanufacturing system under uncertainty within a closed-loop supply chain. Int. J. Prod. Econ. 135(1), 81–93 (2012)

Lage, M., Godinho, M.: Production planning and control for remanufacturing: literature review and analysis. Prod. Plan. Control 23(6), 419–435 (2012)

Li, C.B., Liu, F., Cao, H.J., Wang, Q.L.: A stochastic dynamic programming based model for uncertain production planning of re-manufacturing system. Int. J. Prod. Res. 47(13), 3657–3668 (2009)

Li, J., Gonzales, M., Zhu, Y.: A hybrid simulation optimization method for production planning of dedicated remanufacturing. Int. J. Prod. Econ. 117(2), 286–301 (2009)

Li, Y.J., Chen, J., Cai, X.Q.: Heuristic genetic algorithm for capacitated production planning problems with batch processing and remanufacturing. Int. J. Prod. Econ. 105(2), 301–317 (2007)

Liu, S.S., Papageorgiou, L.G.: Multiobjective optimisation of production, distribution and capacity planning of global supply chains in the process industry. Omega 41(2), 369–382 (2013)

Lusa, A., Matinez-costa, C., Mas-Machura, M.: An integral planning model that includes production, selling price, cash flow management and flexible capacity. Int. J. Prod. Res. 50(6), 1568–1581 (2012)

Merzifonluoglu, Y., Geunes, J., Romeijn, H.E.: Integrated capacity, demand, and production planning with subcontracting and overtime options. Nav. Res. Logist. 54(4), 433–447 (2007)

Naeem, M.A., Dias, D.J., Tibrewal, R., et al.: Production planning optimization for manufacturing and remanufacturing system in stochastic environment. J. Intell. Manuf. 24(4), 717–728 (2013)

Pan, Z.D., Tang, J.F., Liu, O.: Capacitated dynamic lot sizing problems in closed-loop supply chain. Eur. J. Oper. Res. 198(3), 810–821 (2009)

Rockafellar, R.T.: Augmented Lagrangians and application of the proximal point algorithm in convex programming. Math. Oper. Res. 1(2), 97–116 (1976)

Rockafellar, R.T., Wets, R.J.B.: Scenarios and policy aggregation in optimization under uncertainty. Math. Oper. Res. 16(1), 119–147 (1991)

Shi, J.M., Zhang, G.Q., Sha, J.C.: Optimal production planning for a multi-product closed loop system with uncertain demand and return. Comput. Oper. Res. 38(3), 641–650 (2011)

Tang, L.X., Che, P., Liu, J.Y.: A stochastic production planning problem with nonlinear cost. Comput. Oper. Res. 39(9), 1977–1987 (2012)

Tempelmeier, H., Derstroff, M.: A Lagrangean-based heuristic for dynamic multilevel multiitem constrained lotsizing with setup times. Manage. Sci. 42(5), 738–757 (1996)

vanderLaan, E., Salomon, M.: Production planning and inventory control with remanufacturing and disposal. Eur. J. Oper. Res. 102(2), 264–278 (1997)

Zanjani, M.K., Nourelfath, M., Ait-Kadi, D.: A scenario decomposition approach for stochastic production planning in sawmills. J. Oper. Res. Soc. 64(1), 48–59 (2013)

Zhang, J., Liu, X., Tu, Y.L.: A capacitated production planning problem for closed-loop supply chain with remanufacturing. Int. J. Adv. Manuf. Technol. 54(5–8), 757–766 (2011)

Acknowledgements

This work is supported by the Social Sciences Foundation of Anhui Province (No. AHSKQ2016D28), the First Major Project in Anhui Normal University (FRZD201302), the Public Projects of Zhejiang Province (No. 2017C31069), the Natural Science Foundation of Anhui Province (No. 1608085QG167, 1608085MG152), the National Natural Science Foundation of China (No. 71601065, 71231004, 71501058) and the Humanities and Social Sciences Foundation of the Chinese Ministry of Education (No. 15YJC630097). Panos M. Pardalos is partially supported by the project of “Distinguished International Professor by the Chinese Ministry of Education” (MS2014HFGY026).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflicts of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Fang, C., Liu, X., Pardalos, P.M. et al. A stochastic production planning problem in hybrid manufacturing and remanufacturing systems with resource capacity planning. J Glob Optim 68, 851–878 (2017). https://doi.org/10.1007/s10898-017-0500-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10898-017-0500-6