Abstract

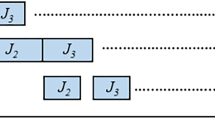

This paper addresses a batch scheduling problem in flow shop production systems, where job families are formed based on setup similarities. In order to improve setup efficiency, we consider batching decisions in our solution procedure. Due to its high practical relevance, the batch availability assumption is also adopted in this study. In the presence of sequence-dependent setup times, it is proved that a permutation flow shop is generally not optimal. Therefore, our objective is to determine solutions with inconsistent batches, which essentially lead to non-permutation schedules, to minimize makespan. After examining structural properties, we develop a tabu search algorithm with multiple neighbourhood functions. Computational results confirm the remarkable benefits of batching decisions. Our algorithm also outperforms some well-known and well-performing approaches.

Similar content being viewed by others

References

Albers, S., & Brucker, P. (1993). The complexity of one-machine batching problems. Discrete Applied Mathematics, 47, 87–107.

Battiti, R., & Giampietro, T. (1994). The [reactive tabu search]. ORSA Journal on Computing, 6, 126–140.

Buscher, U., & Shen, L. (2009). An integrated tabu search algorithm for the lot streaming problem in job shops. European Journal of Operational Research, 199, 385–399.

Campbell, H. G., Dudek, R. A., & Simth, M. L. (1970). A heuristic algorithm for the \(n\) job \(m\) machine sequencing problem. Management Science, 16, B630–B637.

Chang, J. H., & Chiu, H. N. (2005). A comprehensive review of lot streaming. International Journal of Production Research, 43, 1515–1536.

Cheng, T. C. E., Chen, Y. L., & Oguz, C. (1994). One-machine batching and sequencing of multiple-type items. Computers and Operations Research, 21, 717–721.

Cheng, T. C. E., Gordon, V. S., & Kovalyov, M. Y. (1996). Single machine scheduling with batch deliveries. European Journal of Operational Research, 94, 277–283.

Coffman, E. G., Yannakakis, M., Magazine, M. J., & Santos, C. A. (1990). Batch sizing and job sequencing on a single machine. Annals of Operations Research, 26, 135–147.

Franca, P. M., Gupta, J. N. D., Mendes, A. S., Moscato, P., & Veltink, K. J. (2005). Evolutionary algorithms for scheduling a flowshop manufacturing cell with sequence dependent family setups. Computers and Industrial Engineering, 48, 491–506.

Gupta, J. N. D., & Stafford, E. F. (2006). Flowshop scheduling research after five decades. European Journal of Operational Research, 169, 699–711.

Gupta, J. N. D., & Tunc, E. A. (1994). Scheduling a two-stage hybrid flowshop with separable setup and removal times. European Journal of Operational Research, 77, 415–428.

Hall, N. G., Laporte, G., Selvarajah, E., & Sriskandarajah, C. (2003). Scheduling and lot streaming in [flowshops with no-wait] in process. Journal of Scheduling, 6, 339–354.

Hendizadeh, S. H., Faramarzi, H., Mansouri, S. A., Gupta, J. N. D., & Eimekkawy, T. Y. (2008). Mata-heuristics for scheduling a flowline manufacturing cell with sequence dependent family setup times. International Journal of Production Economics, 111, 593–605.

Hochbaum, D. S., & Landy, D. (1994). Scheduling with batching: Minimizing the weighted number of tardy jobs. Operations Research Letters, 16, 79–86.

Hurink, J. (1998). A tabu search approach for a single-machine batching problem using an efficient method to calculate a best neighbor. Journal of Scheduling, 1, 127–148.

Lin, S. W., Gupta, J. N. D., Ying, K. C., & Lee, Z. J. (2009). Using simulated annealing to schedule a flowshop manufacturing cell with sequence-dependent family setup times. International Journal of Production Research, 47, 3205–3217.

Logendran, R., de Szoeke, P., & Barnard, F. (2006). Sequence-dependent group scheduling problems in flexible flow shops. International Journal of Production Economics, 102, 66–86.

Mosheiov, G., & Oron, D. (2005). A note on flow-shop and job-shop batch scheduling with identical processing-time jobs. European Journal of Operational Research, 161, 285–291.

Mosheiov, G., & Oron, D. (2008). Open-shop batch scheduling with identical jobs. European Journal of Operational Research, 187, 1282–1292.

Mosheiov, G., Oron, D., & Ritov, Y. (2004). Flow-shop batching scheduling with identical processing-time jobs. Naval Research Logistics, 51, 783–799.

Nawaz, M., Enscore, E., & Ham, I. (1983). A heuristic algorithm for the \(m\)-machine, \(n\)-job flow shop sequencing problem. OMEGA International Journal of Management Science, 11, 91–95.

Neufeld, J. S., Gupta, J. N. D., & Buscher, U. (2015). Minimizing makespan in flowshop group scheduling with sequence-dependent family set-up times using inserted idle times. International Journal of Production Research, 53, 1791–1806.

Neufeld, J. S., Gupta, J. N. D., & Buscher, U. (2016). A comprehensive review of flowshop group scheduling literature. Computers and Operations Research, 70, 56–74.

Nowicki, E., & Smutnicki, C. (1996). A fast taboo search algorithm for the job shop problem. Management Science, 42, 797–813.

Potts, C. N., & Kovalyov, M. Y. (2000). Scheduling with batching: A review. European Journal of Operational Research, 120, 228–249.

Reddy, V., & Narendran, T. T. (2003). Heuristics for scheduling sequence-dependent set-up jobs in flow line cells. International Journal of Production Research, 41, 193–206.

Schaller, J. E., Gupta, J. N. D., & Vakharia, A. J. (2000). Scheduling a flowline manufacturing cell with sequence dependent family setup times. European Journal of Operational Research, 125, 324–339.

Shen, L., Gupta, J.N.D. (2015) Family scheduling with batch availability in flow shops. In Proceedings of the 7th multidisciplinary international scheduling conference.

Shen, L., Gupta, J. N. D., & Buscher, U. (2014). Flow shop batching and scheduling with sequence-dependent setup times. Journal of Scheduling, 17, 353–370.

Sung, C. S., Kim, Y. H., & Yoon, S. H. (2000). A problem reduction and decomposition approach for scheduling for a flowshop of batch processing machines. European Journal of Operational Research, 121, 179–192.

van der Zee, D. (2013). Family based dispatching with batch availability. International Journal of production Research, 51, 3643–3653.

van Hoesel, S., Wagelmans, A., & Moerman, B. (1994). Using geometric techniques to improve dynamic programming algorithms for the economic lot-sizing problems and extensions. European Journal of Operational Research, 75, 312–331.

Webster, S., & Baker, K. R. (1995). Scheduling groups of jobs on a single machine. Operations Research, 43, 692–703.

Ying, K. C., Gupta, J. N. D., Lin, S. W., & Lee, Z. J. (2010). Permutation and non-permutation schedules for the flowline manufacturing cell with sequence dependent family setups. International Journal of Production Research, 48, 2169–2184.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shen, L., Gupta, J.N.D. Family scheduling with batch availability in flow shops to minimize makespan. J Sched 21, 235–249 (2018). https://doi.org/10.1007/s10951-017-0529-x

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10951-017-0529-x