Abstract

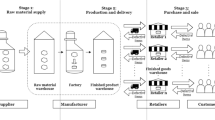

Considering the ethylene effect and the perspective of learning theory from an interdisciplinary perspective, this paper studies the optimal inventory management of deteriorating items’ two-stage supply chain consisting of suppliers and retailers. It is suggested that the inventory level of the two-stage supply chain will affect the dynamic deterioration problem of deterioration degree through the ethylene intensity coefficient. Based on the learning effect theory, the two-stage inventory model of deteriorating items’ supply chain is constructed. By analyzing the cost structure under the influence of learning effect of suppliers and retailers, the profit of supply chain is solved by optimization method and optimal price and optimal learning coefficient are derived. The optimal solution of learning coefficient is obtained from various scenarios with theoretical analysis. Meanwhile, the influence of learning effect coefficient on system profit is compared under different ethylene intensity levels. Finally, the paper presents a numerical example to illustrate the rationality and applications of theoretical results. Through this research, it is aimed to reveal the multimedia system could be used to show the data change to help the business decision be more reasonable to attain more profit for managers. Furthermore, the multimedia technology could intensify the learning effect and in return could maximize the system profit of supply chain. This work is mainly modeling analysis, while the research outcomes could be developed into a good system by using multimedia technology.

Similar content being viewed by others

References

Achabal DD, McIntyre S, Smith SA (1990) Maximizing profits from periodic department store promotions. J Retail 66(4):383

Alamri AA, Balkhi ZT (2007) The effects of learning and forgetting on the optimal production lot size for deteriorating items with time varying demand and deterioration rates. Int J Prod Econ 107(1):125–138

Balakrishnan A, Pangburn MS, Stavrulaki E (2004) “Stack Them High, Let’em Fly”: Lot-Sizing Policies When Inventories Stimulate Demand. Manag Sci 50(5):630–644

Balakrishnan A, Pangburn MS, Stavrulaki E (2008) Integrating the promotional and service roles of retail inventories. Manufacturing & Service Operations Management 10(2):218–235

Biskup D (2008) A state-of-the-art review on scheduling with Learning effect. Eur J Oper Res 188(2):315–329

Carbonara N, Pellegrino R (2017) How do supply chain risk management flexibility-driven strategies perform in mitigating supply disruption risks? International Journal of Integrated Supply Management 11(4):354–379

Chan HL, Shen B, Cai Y (2017) Quick response strategy with cleaner technology in a supply chain: coordination and win-win situation analysis. Int J Prod Res 1:1–12

Chang CT, Teng JT, Chern MS (2010) Optimal manufacturer’s replenishment policies for deteriorating items in a supply chain with up-stream and down-stream trade credits. Int J Prod Econ 127(1):197–202

Chen C-K, Lo C-C, Liao Y-X (2008) Optimal lot size with learning consideration on an imperfect production system with allowable shortages. Int J Prod Econ 113(1):459–469

Chen T-H, Tsao Y-C (2014) Optimal lot-sizing integration policy under learning and rework effects in a manufacturer–retailer chain. Int J Prod Econ 155:239–248

Fisher ML, Hammond JH (1994) Making supply meet demand in an uncertainty world. Harv Bus Rev 72(5–6):83–93

Genovese A, Acquaye AA, Figueroa A, Koh SL (2017) Sustainable supply chain management and the transition towards a circular economy: Evidence and some applications. Omega 66:344–357

Ghare PM, Schrader GF (1963) A model for exponentially decaying inventory. J Ind Eng 14(5):238–243

Jaber MY, Bonney M (1996) Optimal lot sizing under learning considerations: The bounded learning case. Appl Math Model 20(10):36–38

Jaber MY, Bonney M (2007) Economic manufacture quantity (EMQ) model with lot-size dependent learning and forgetting rates. Int J Prod Econ 108(1):359–367

Jaber MY, Guiffrida AL (2004) Learning curves for processes generating defects requiring reworks. Eur J Oper Res 159(3):663–672

Jana DK, Pramanik S, Maiti M (2016) Mean and CV reduction methods on Gaussian type-2 fuzzy set and its application to a multilevel profit transportation problem in a two-stage supply chain network. Neural Comput & Applic:1–24

Karimi M, Niknamfar AH, Pasandideh SHR (2017) Two-stage single period inventory management for a manufacturing vendor under green-supplier supply chain. Int J Syst Assur Eng Manag 8(4):1–15

Keachie EC, Fontana RJ (1966) Effects of learning on optimal lot size. Manag Sci 13(2):102–108

Koschat MA (2008) Store inventory can affect demand: empirical evidence from magazine retailing. J Retail 84(2):165–179

Lee JH, Pilkington M (2017) How the blockchain revolution will reshape the consumer electronics industry [Future Directions]. IEEE Consumer Electronics Magazine 6(3):19–23

Lee W-C, Chin-Chia W (2009) Some single machine and m-machine flowshop scheduling problems with learning considerations. Inf Sci 179(22):3885–3892

Li G, Luo M-L, Zhang W-J et al (2015) Single-machine due-window assignment scheduling based on common flow allowance, learning effect and resource allocation. Int J Prod Res 53(4):1228–1241

Michalski M, Montes-Botella JL, Narasimhan R (2018) The impact of asymmetry on performance in different collaboration and integration environments in supply chain management. Supply Chain Management: An International Journal 23(1):33–49

Petruzzi NC, Dada M (1999) Pricing and the newsvendor problem: A review with extensions. Oper Res 47(2):183–194

Smunt TL, Meredith J (2000) A comparison of direct cost savings between flexible automation and labor with learning. Prod Oper Manag 9(2):158–170

Theodore P (1936) Wright. Factors affecting the cost of airplanes. Journal of Aeronautical. Sciences 3(4):122–128

Tomás-Barberán FA, Espin JC (2001) Phenolic compounds and related enzymes as determinants of quality in fruits and vegetables. J Sci Food Agric 81(9):853–876

Tsao Y-C, Chen T-H, Pei-Ying W (2013) Effects of lot-sizing integration and learning effect on managing imperfect items in a manufacturer-retailer chain. J Appl Math 2013

Vanpoucke E, Vereecke A, Muylle S (2017) Leveraging the impact of supply chain integration through information technology. Int J Oper Prod Manag 37(4):510–530

Wahab MIM, Jaber MY (2010) Economic order quantity model for items with imperfect quality, different holding costs, and Learning effect: A note. Comput Ind Eng 58(1):186–190

Wang J-B, Wang M-Z (2014) Single-machine due-window assignment and scheduling with learning effect and resource-dependent processing times. Asia-Pacific Journal of Operational Research 31:05

Wolfe HB (1968) A model for control of style merchandise. Industrial Management Review 9(2):69–82

Yang N, Zhang R (2014) Dynamic Pricing and Inventory Management Under Inventory-Dependent Demand. Operations Rsearch 62(5):1077–1094

Yılmaz ÖF, Pardalos PM (2017) Minimizing average lead time for the coordinated scheduling problem in a two-stage supply chain with multiple customers and multiple manufacturers. Comput Ind Eng 114:244–247

Acknowledgements

This research is supported by:

1. National Natural Science Foundation Youth Project (No. 71102146).

2. Guangdong Provincial Natural Science Foundation Project (No. S2012010010649).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Liu, M., Zuo, X., Lan, XG. et al. Two-stage supply chain study of deteriorating items considering the double effect for multimedia systems. Multimed Tools Appl 78, 4655–4672 (2019). https://doi.org/10.1007/s11042-018-6456-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11042-018-6456-9