Abstract

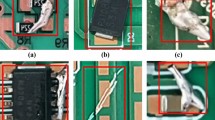

The detection of surface defects in industrial products is vital for ensuring product quality. Ensuring real-time performance, while improving the detection accuracy of low-pixel-resolution small defects against background interference poses a significant challenge. To address this, the EA-YOLO model, based on Yolov8, is proposed. It includes three main improvements: replacing C2f (Faster Implementation of CSP Bottleneck with 2 convolutions) with a specially designed C2FN (Faster Implementation of CSP FastNet Block with 2 convolutions Network) in the backbone module to reduce parameters and GFLOPs, while enhancing speed; introducing the Environmental Awareness Dynamic Network (EADN) to prevent the loss of defect information in extreme positions; and using the improved Dynamic Adaptive Fusion Detector (DAF-Detect) for predictions. Case studies with the NEU-DET and PCB-DET datasets show that EA-YOLO achieves a mAP of 81.1 and 97.8%, respectively, improving by 4.3 and 4.1% compared to the baseline model, with reduced parameters, GFLOPs, and increased FPS, demonstrating good robustness and generalization ability.

Similar content being viewed by others

Data availability

No datasets were generated or analyzed during the current study.

References

Yun JP, Choi S, Kim SW (2009) Vision-based defect detection of scale-covered steel billet surfaces. Opt Eng 48:037205-037205–037209

Zheng X, Chen J, Wang H et al (2021) A deep learning-based approach for the automated surface inspection of copper clad laminate images. Appl Intell 51:1262–1279

Li Z, Wei X, Hassaballah M et al (2024) A deep learning model for steel surface defect detection. Complex Intell Syst 10(1):885–897

Liu W, Anguelov D, Erhan D, et al (2016) Ssd: single shot multibox detector//Computer Vision–ECCV 2016: 14th European Conference, Amsterdam, The Netherlands, Oct 11–14, 2016, Proceedings, Part I 14. Springer International Publishing, pp 21–37

She Y, Li H (2023) A deep learning based dislocation detection method for cylindrical silicon growth process. Appl Intell 53(8):9188–9203

Bharati P, Pramanik A (2020) Deep learning techniques—R-CNN to mask R-CNN: a survey. Computational Intelligence in Pattern Recognition: Proceedings of CIPR 2019, pp 657–668

Ren S, He K, Girshick R et al (2016) Faster R-CNN: towards real-time object detection with region proposal networks. IEEE Trans Pattern Anal Mach Intell 39(6):1137–1149

Wang M, Zhou Y (2024) Autonomous rail surface defect identification based on an improved one-stage object detection algorithm. J Perform Constr Facil 38(5):04024041

Zhao BT, Chen YR, Jia XF et al (2024) Steel surface defect detection algorithm in complex background scenarios. Measurement 237:115189

Hu H, Zhang Z, Xie Z, et al (2019) Local relation networks for image recognition. Proceedings of the IEEE/CVF international conference on computer vision, pp 3464–3473

Yun J P, Choi S H, Kim S W (2009) Vision-based defect detection of scale-covered steel billet surfaces. Opt Eng 48(3):037205–037205-9.

Wang Y, Xia H, Yuan X et al (2018) Distributed defect recognition on steel surfaces using an improved random forest algorithm with optimal multi-feature-set fusion. Multimed Tools Appl 77:16741–16770

Zhang J, Wang H, Tian Y et al (2020) An accurate fuzzy measure-based detection method for various types of defects on strip steel surfaces. Comput Ind 122:103231

He Y, Song K, Meng Q, Yan Y (2019) An end-to-end steel surface defect detection approach via fusing multiple hierarchical features. IEEE Trans Instrum Meas 69:1493–1504

Cha YJ, Choi W, Suh G et al (2018) Autonomous structural visual inspection using region-based deep learning for detecting multiple damage types. Comput-Aided Civ Infrastruct Eng 33(9):731–747

Hou S, Dong B, Wang H et al (2020) Inspection of surface defects on stay cables using a robot and transfer learning. Autom Constr 119:103382

Xue M, Chen M, Peng D et al (2021) One spatio-temporal sharpening attention mechanism for light-weight YOLO models based on sharpening spatial attention. Sensors 21(23):7949

Chen W, Huang Z, Mu Q et al (2022) PCB defect detection method based on transformer-YOLO. IEEE Access 10:129480–129489

Jung H, Rhee J (2022) Application of YOLO and ResNet in heat staking process inspection. Sustainability 14(23):15892

Li M, Wang H, Wan Z (2022) Surface defect detection of steel strips based on improved YOLOv4. Comput Electr Eng 102:108208

Xing J, Jia M (2021) A convolutional neural network-based method for workpiece surface defect detection. Measurement 176:109185

Ying Z, Lin Z, Wu Z et al (2022) A modified-YOLOv5s model for detection of wire braided hose defects. Measurement 190:110683

Lin T Y, Dollár P, Girshick R, et al (2017) Feature pyramid networks for object detection//Proceedings of the IEEE conference on computer vision and pattern recognition, pp 2117–2125

Liu Z, Tang R, Duan G et al (2021) TruingDet: Towards high-quality visual automatic defect inspection for mental surface. Opt Lasers Eng 138:106423

Dong H, Yuan M, Wang S et al (2023) PHAM-YOLO: a parallel hybrid attention mechanism network for defect detection of meter in substation. Sensors 23(13):6052

Wang Y, Wang H, Xin Z (2022) Efficient detection model of steel strip surface defects based on YOLO-V7. IEEE Access 10:133936–133944

Chen J, Kao S, He H, et al (2023) Run, don't walk: chasing higher FLOPS for faster neural networks//Proceedings of the IEEE/CVF conference on computer vision and pattern recognition, pp 12021–12031

Dai X, Chen Y, Xiao B, et al (2021) Dynamic head: unifying object detection heads with attentions[C]//Proceedings of the IEEE/CVF conference on computer vision and pattern recognition, pp 7373–7382

Zhao C, Shu X, Yan X et al (2023) RDD-YOLO: a modified YOLO for detection of steel surface defects. Measurement 214:112776

Zhang Y, Zhang H, Huang Q et al (2024) DsP-YOLO: an anchor-free network with DsPAN for small object detection of multiscale defects. Expert Syst Appl 241:122669

Jocher G, Chaurasia A, Stoken A, et al (2022) ultralytics/yolov5: v6. 1-tensorrt, tensorflow edge tpu and openvino export and inference. Zenodo

Ge Z, Liu S, Wang F, et al (2021) Yolox: exceeding yolo series in 2021. arxiv preprint arxiv:2107.08430

Wang CY, Bochkovskiy A, Liao HYM (2023) YOLOv7: trainable bag-of-freebies sets new state-of-the-art for real-time object detectors. Proceedings of the IEEE/CVF conference on computer vision and pattern recognition, pp 7464–7475

Xie W, Sun X, Ma W (2024) A light weight multi-scale feature fusion steel surface defect detection model based on YOLOv8. Meas Sci Technol 35(5):055017

Liu R, Huang M, Gao Z et al (2023) MSC-DNet: an efficient detector with multi-scale context for defect detection on strip steel surface. Measurement 209:112467

Zhang D, Hao X, Wang D et al (2023) An efficient lightweight convolutional neural network for industrial surface defect detection. Artif Intell Rev 56(9):10651–10677

Acknowledgements

This research received specific grant from National High Technology Research Development Plan (2013AA041106), National Natural Science Foundation (62073213), China Postdoctoral Science Foundation (2014M561458), Shanghai Natural Science Foundation of China (23ZR1426700), Shanghai Engineering Technology Research Center Construction projects (20DZ2253300).

Author information

Authors and Affiliations

Contributions

BL was involved in writing–original draft, software, methodology. BW was involved in supervision, writing–review & editing, investigation. XH was involved in funding acquisition, validation. JZ was involved in drawing diagrams, data validation; CJ was involved in software, data validation.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Li, B., Wang, B., Hu, X. et al. A small defect detection technique for industrial product surfaces based on the EA-YOLO model. J Supercomput 81, 415 (2025). https://doi.org/10.1007/s11227-025-06929-0

Accepted:

Published:

DOI: https://doi.org/10.1007/s11227-025-06929-0