Abstract

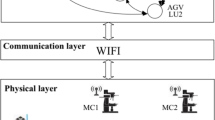

The level of performance is an important aspect of the design and control in a production line. Particularly, the level of performance of variable production line (VPL) is one of the most important influential factors in deciding production line’s flexibility. The majority of the existing solution methods for performance prediction and evaluation problems of VPL assume that the processing times, time between failures and repair times are deterministic or exponentially distributed, which could not be applied to all the problems in real cases. This paper relaxes these restrictions by proposing an ARENA simulation model for performance prediction and evaluation based on the variability theory in Factory Physics. The variable properties of time interval between product arrivals and VPL are simulated, which combining with the coefficients of variations, are presented. Through the simulation, how the variable factors influence the performance of VPL is demonstrated. The methodology in this paper can be applied to effectively predict and evaluate the performance in VPL in various production scenarios before implementing them in reality.

Similar content being viewed by others

References

Abdul-Kader, W., & Gharbi, A. (2002). Capacity estimation of a multi-product unreliable production line. International Journal of Production Research, 40(18), 4815–4834.

Tayfur Altiok, B. M. (2007). Simulation modeling and analysis with Arena. Burlington: Elsevier.

Jarrahi, F., & Abdul-Kader, W. (2015). Performance evaluation of a multi-product production line: An approximation method. Applied Mathematical Modelling, 39(13), 3619–3636.

Almeida, D. D., Gourgand, M., & Kellert, P. (1998). Performance evaluation of a job-shop-like flexible manufacturing system with transfer blocking using a Markovian queuing network model. International Journal of Computer Integrated Manufacturing, 11(3), 205–216.

Aziz, A., Jarrahi, F., & Abdul-Kader, W. (2010). Modeling and performance evaluation of a series-parallel flow line system with finite buffers. Information Systems and Operational Research, 48(2), 103–120.

Schwarz, J. A., & Epp, M. (2015). Performance evaluation of a transportation-type bulk queue with generally distributed inter-arrival times. International Journal of Production Research, 54(20), 6251–6264.

Lee, H., & Seo, D.-W. (2016). Performance evaluation of WIP-controlled line production systems with constant processing times. Computers & Industrial Engineering, 94, 138–146.

Shanthikumar, J. G., Ding, S., & Zhang, M. T. (2007). Queueing theory for semiconductor manufacturing systems: A survey and open problems. IEEE Transactions on Automation Science and Engineering, 4(4), 513–522.

Mehmet, P., Mustafa, Y., & Bilal, T. (2016). Variability modelling and balancing of stochastic assembly lines. International Journal of Production Research, 54(19), 5761–5782.

Amiri, M., & Mohtashami, A. (2011). Buffer allocation in unreliable production lines based on design of experiments, simulation, and genetic algorithm. International Journal of Advanced Manufacturing Technology, 62(1–4), 371–383.

Wu, K., Zhou, Y., & Zhao, N. (2016). Variability and the fundamental properties of production lines. Computers & Industrial Engineering, 99, 364–371.

Smith, J. M. (2013). System capacity and performance modelling of finite buffer queueing networks. International Journal of Production Research, 52(11), 3125–3163.

Damodaran, P., & Hulett, M. (2012). Analytical approximations to predict performance measures of manufacturing systems with general distributions, job failures and parallel processing. European Journal of Operational Research, 221(1), 74–86.

Ghafour, K., Ramli, R., & Zaibidi, N. Z. (2017). Developing a M/G/C-FCFS queueing model with continuous review (R, Q) inventory system policy in a cement industry. Journal of Intelligent & Fuzzy Systems, 32(6), 4059–4068.

Belmansour, A. T., & Nourelfath, M. (2008). An aggregation method for performance evaluation of a tandem homogenous production line with machines having multiple failure modes. Reliability Engineering & System Safety, 95(11), 1193–1201.

Cauffriez, L., & Willaeys, D. (2006). A predictive model for improving production line performance. International Journal of Advanced Manufacturing Technology, 29(9–10), 969–979.

McNamara, T., Shaaban, S., & Hudson, S. (2013). Simulation of unbalanced buffer allocation in unreliable unpaced production lines. International Journal of Production Research, 51(6), 1922–1936.

Padhi, S. S., Wagner, S. M., Niranjan, T. T., & Aggarwal, V. (2013). A simulation-based methodology to analyse production line disruptions. International Journal of Production Research, 51(6), 1885–1897.

Lavoie, P., Kenné, J. P., & Gharbi, A. (2007). Production control and combined discrete/continuous simulation modeling in failure-prone transfer lines. International Journal of Production Research, 45(24), 5667–5685.

Zhang, X., Schmidt, L., Schlick, C. M., Reuth, R., & Luczak, H. (2008). A human task-oriented simulation study in autonomous production cells. International Journal of Production Research, 46(18), 5013–5041.

Padhi, S. S., & Mohapatra, P. K. J. (2009). Process evaluation of award of work contracts in a government department. International Journal of Electronic Governance, 2(2/3), 118–130.

Wu, K., & Zhao, N. (2015). Analysis of dual tandem queues with a finite buffer capacity and non-overlapping service times and subject to breakdowns. IIE Transactions, 47(12), 1329–1341.

Abdul-Kader, W. (2003). Simulation of an unreliable production line. Journal of Decision Systems, 12(1), 31–46.

Betterton, C. E., & Cox Iii, J. F. (2012). Production rate of synchronous transfer lines using Monte Carlo simulation. International Journal of Production Research, 50(24), 7256–7270.

Hsieh, S.-J. (2002). Hybrid analytic and simulation models for assembly line design and production planning. Simulation Modelling Practice and Theory, 10(1–2), 87–108.

Onggo, B. S., & Karatas, M. (2016). Test-driven simulation modelling: A case study using agent-based maritime search-operation simulation. European Journal of Operational Research, 254(2), 517–531.

Kim, T., & Choi, B. K. (2014). Production system-based simulation for backward on-line job change scheduling. Simulation Modelling Practice and Theory, 40, 12–27.

Kenné, J. (2009). Optimization of production control policies in failure-prone homogenous transfer lines. IIE Transactions, 41(3), 209–222.

Zahraee, S. M., Haghighi, M., Afshar, J., Golroudbary, S. R., & Hashemi, A. (2014). Simulation of manufacturing production line based on Arena. Advanced Materials Research, 933, 744–748.

McDonald, T., Aken, E. V., & Elli, K. (2012). Utilizing simulation to evaluate production line performance under varying demand conditions. International Journal of Industrial Engineering Computations, 3, 3–14.

Kamrani, M., Hashemi Esmaeil Abadi, S. M., & Rahimpour Golroudbary, S. (2014). Traffic simulation of two adjacent unsignalized T-junctions during rush hours using Arena software. Simulation Modelling Practice and Theory, 49, 167–179.

Hopp, W. J., & Spearman, M. L. (2002). Factory physics: Foundations of manufacturing management (2nd ed.). Peking: Tsinghua Press.

Toledo, T., Koutsopoulos, H. N., Davol, A., Ben-Akiva, M. E., Burghout, W., Andréasson, I., et al. (2003). Calibration and validation of microscopic traffic simulation tools: Stockholm case study. Transportation Research Record: Journal of the Transportation Research Board, 1831, 65–75.

Acknowledgements

The authors are thankful to the anonymous reviewers for their constructive and helpful comments that have led to this much improved manuscript. This work was supported by the National Natural Science Foundation of China (Grant: 71671026) and Science & Technology Department of Sichuan Province (Grant: 18ZDYF2575).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, C., Liu, J. & Li, B. Performance Prediction and Evaluation Based on the Variability Theory in Production Lines Using ARENA Simulation. Wireless Pers Commun 103, 897–920 (2018). https://doi.org/10.1007/s11277-018-5486-y

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11277-018-5486-y