Abstract

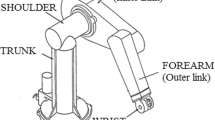

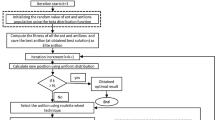

In this work, Coyote optimization algorithm (COA) is used for inverse kinematics optimization of a 7 degrees-of-freedom Kuka robot. The Denavit–Hartenberg (D–H) Convention approach is used to compute the forward kinematics of the robotic arm. The fitness functions based on sum of squares of distance and torque are employed to compute the optimized inverse kinematics solution using the COA. A comparative analysis has been conducted with other optimization algorithms including genetic algorithm (GA), particle swarm optimization (PSO) and Grey wolf optimization (GWO), artificial bee colony (ABC) optimization, and whale optimization algorithm (WOA) to evaluate the performance of the proposed approach. The experimental results show that the COA leads to least computation error of \(3.59 \times 10^{-7}\) and computation time of 1.405 s as compared to GA, PSO, GWO, ABC, and WOA algorithms. Further, jerk being control input has a major impact on the efficiency of robotic arm. COA is employed to obtain the optimal joint parameters, such as joint velocity, joint acceleration, and joint jerk, respectively. This leads to a minimum jerk trajectory which contributes to the smooth movement of Kuka arm. The simulation of Kuka robotic arm for pick and place operations is performed in CoppeliaSim, which further justifies its usage for real-time applications.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Data availability

The manuscript has no associated data.

References

Moshaii AA, Masouleh MT, Zarezadeh E, et al (2015) Static analysis of a 3-RRS and a 3-RSR spherical parallel robots. In: 2015 3rd RSI international conference on robotics and mechatronics (ICROM), IEEE, pp 800–804

Guan T (2021) Research on the application of robot welding technology in modern architecture. Int J Syst Assur Eng Manag 14(2):681–690

Luo H, Zhao F, Guo S et al (2021) Mechanical performance research of friction stir welding robot for aerospace applications. Int J Adv Robot Syst 18(1):1729881421996543

Asadi K, Haritsa VR, Han K et al (2021) Automated object manipulation using vision-based mobile robotic system for construction applications. J Comput Civil Eng 35(1):04020058

Parascho S, Han IX, Walker S et al (2020) Robotic vault: a cooperative robotic assembly method for brick vault construction. Constr Robot 4(3):117–126

Abbasi A, MahmoudZadeh S, Yazdani A et al (2022) Feasibility assessment of Kian-I mobile robot for autonomous navigation. Neural Comput Appl 34:1199–1218

Al Tahtawi AR, Agni M, Hendrawati TD (2021) Small-scale robot arm design with pick and place mission based on inverse kinematics. J Robot Control (JRC) 2(6):469–475

Yenorkar R, Chaskar U (2018) Gui based pick and place robotic arm for multipurpose industrial applications. In: 2018 Second international conference on intelligent computing and control systems (ICICCS), IEEE, pp 200–203

Wang H, Wang H, Huang J et al (2019) Smooth point-to-point trajectory planning for industrial robots with kinematical constraints based on high-order polynomial curve. Mech Mach Theory 139:284–293

Krämer M, Muster FI, Roesmann C et al (2021) An optimization-based approach for elasticity-aware trajectory planning of link-elastic manipulators. Mechatronics 75:102523

Gattringer H, Mueller A, Oberherber M et al (2022) Time-optimal robotic manipulation on a predefined path of loosely placed objects: modeling and experiment. Mechatronics 84:102753

Qiu S, Kermani MR (2021) Precision grasp using an arm-hand system as a hybrid parallel-serial system: a novel inverse kinematics solution. IEEE Robot Autom Lett 6(4):8530–8536

da Fonseca VP, Jiang X, Petriu EM et al (2022) Tactile object recognition in early phases of grasping using underactuated robotic hands. Intell Serv Robot 15(4):513–525

Pellicciari M, Berselli G, Leali F et al (2013) A method for reducing the energy consumption of pick-and-place industrial robots. Mechatronics 23(3):326–334

Spong MW, Hutchinson S, Vidyasagar M (2020) Robot modeling and control. Wiley, New York

Cox D, Little J, OShea D (2013) Ideals, varieties, and algorithms: an introduction to computational algebraic geometry and commutative algebra. Springer, Berlin

Raghavan M, Roth B (1993) Inverse kinematics of the general 6r manipulator and related linkages. J Mech Des 115(3):502–508

Shimizu M, Kakuya H, Yoon WK et al (2008) Analytical inverse kinematic computation for 7-DOF redundant manipulators with joint limits and its application to redundancy resolution. IEEE Trans Robot 24(5):1131–1142

Tong Y, Liu J, Liu Y et al (2021) Analytical inverse kinematic computation for 7-DOF redundant sliding manipulators. Mech Mach Theory 155:104006

Safeea M, Bearee R, Neto P (2021) A modified DLS scheme with controlled cyclic solution for inverse kinematics in redundant robots. IEEE Trans Ind Inform 17(12):8014–8023

Manocha D, Canny JF (1994) Efficient inverse kinematics for general 6r manipulators. IEEE Trans Robot Autom 10(5):648–657

Kucuk S (2013) Energy minimization for 3-RRR fully planar parallel manipulator using particle swarm optimization. Mech Mach Theory 62:129–149

Momani S, Abo-Hammour ZS, Alsmadi OM (2016) Solution of inverse kinematics problem using genetic algorithms. Appl Math Inf Sci 10(1):225

Abdor-Sierra JA, Merchán-Cruz EA, Rodríguez-Cañizo RG (2022) A comparative analysis of metaheuristic algorithms for solving the inverse kinematics of robot manipulators. Results Eng 16:100597

Nyong-Bassey B, Epemu AM (2022) Inverse kinematics analysis of novel 6-DOF robotic arm manipulator for oil and gas welding using meta-heuristic algorithms. Int J Robot, Autom Sci 4:13–22

Lan Y, Chen X (2020) Trajectory tracking system of wheeled robot based on immune algorithm and sliding mode variable structure. Intell Serv Robot 16:231–241

Moschos I, Parisses C (2022) A novel optimal PI\(\lambda \)DND2N2 controller using coyote optimization algorithm for an AVR system. Eng Sci Technol Int J 26:100991

Tabak A, Duman S (2022) Levy flight and fitness distance balance-based coyote optimization algorithm for effective automatic generation control of pv-based multi-area power systems. Arab J Sci Eng 47(11):14757–14788

Taleb SM, Meraihi Y, Gabis AB et al (2022) Solving the mesh router nodes placement in wireless mesh networks using coyote optimization algorithm. IEEE Access 10:52744–52759

Reddy VK, AV RK (2022) Multi-channel neuro signal classification using adam-based coyote optimization enabled deep belief network. Biomed Signal Process Control 77:103774

Pierezan J, Coelho LDS (2018) Coyote optimization algorithm: a new metaheuristic for global optimization problems. In: 2018 IEEE congress on evolutionary computation (CEC), IEEE, pp 1–8

Rezk H, Fathy A, Aly M (2021) A robust photovoltaic array reconfiguration strategy based on coyote optimization algorithm for enhancing the extracted power under partial shadow condition. Energy Rep 7:109–124

Chang GW, Chinh NC (2020) Coyote optimization algorithm-based approach for strategic planning of photovoltaic distributed generation. IEEE Access 8:36180–36190

Abdelwanis MI, Abaza A, El-Sehiemy RA et al (2020) Parameter estimation of electric power transformers using coyote optimization algorithm with experimental verification. IEEE Access 8:50036–50044

Yuan Z, Wang W, Wang H et al (2020) Developed coyote optimization algorithm and its application to optimal parameters estimation of PEMFC model. Energy Rep 6:1106–1117

Ram R, Pathak PM, Junco S (2019) Inverse kinematics of mobile manipulator using bidirectional particle swarm optimization by manipulator decoupling. Mech Mach Theory 131:385–405

Dereli S, Köker R (2020) A meta-heuristic proposal for inverse kinematics solution of 7-DOF serial robotic manipulator: quantum behaved particle swarm algorithm. Artif Intell Rev 53:949–964

Dereli S, Köker R (2020) Simulation based calculation of the inverse kinematics solution of 7-DOF robot manipulator using artificial bee colony algorithm. SN Appl Sci 2:1–11

Yin S, Luo Q, Zhou G et al (2022) An equilibrium optimizer slime mould algorithm for inverse kinematics of the 7-DOF robotic manipulator. Sci Rep 12(1):9421

Sharma S, Kraetzschmar GK, Scheurer C, et al (2012) Unified closed form inverse kinematics for the KUKA youBot. In: ROBOTIK 2012; 7th German Conference on Robotics, VDE, pp 1–6

Wu H, Zhang X, Song L et al (2022) A hybrid improved bro algorithm and its application in inverse kinematics of 7r 6dof robot. Adv Mech Eng 14(3):16878132221085124

Ibarra-Pérez T, Ortiz-Rodríguez JM, Olivera-Domingo F et al (2022) A novel inverse kinematic solution of a 6-DOF robot using neural networks based on the Taguchi optimization technique. Appl Sci 12(19):9512

Ghosh A, Singh O, Ray AK (2022) Inverse kinematic solution of a 7 DOF robotic manipulator using boundary restricted particle swarm optimization. IFAC-PapersOnLine 55(1):101–105

Singh G, Banga VK (2022) Kinematics and trajectory planning analysis based on hybrid optimization algorithms for an industrial robotic manipulators. Soft Comput 26(21):11339–11372

Shrivastava A, Dalla VK (2022) Jerk optimized motion planning of redundant space robot based on grey-wolf optimization approach. Arabian J Sci Eng 48(3):2687–2699

Wu P, Wang Z, Jing H et al (2022) Optimal time-jerk trajectory planning for delta parallel robot based on improved butterfly optimization algorithm. Appl Sci 12(16):8145

Zhao J, Zhu X, Song T (2022) Serial manipulator time-jerk optimal trajectory planning based on hybrid IWOA-PSO algorithm. IEEE Access 10:6592–6604

Deng H, Zhu L, Wang J, et al (2022) Kinematics modeling and trajectory planning of KUKA manipulator based on MATLAB. In: Journal of physics: conference series, IOP Publishing, p 012056

Parikh PJ, Lam SS (2005) A hybrid strategy to solve the forward kinematics problem in parallel manipulators. IEEE Trans Robot 21(1):18–25

Chen D, Zhang Y (2017) Jerk-level synchronous repetitive motion scheme with gradient-type and zeroing-type dynamics algorithms applied to dual-arm redundant robot system control. Int J Syst Sci 48(13):2713–2727

Nguyen TT, Pham TD, Kien LC, et al (2020) Improved coyote optimization algorithm for optimally installing solar photovoltaic distribution generation units in radial distribution power systems. In: Complexity 2020

Dereli S, Köker R (2018) IW-PSO approach to the inverse kinematics problem solution of a 7-DOF serial robot manipulator. Sigma J Eng Nat Sci 36(1):77–85

Yang X, Zhao Z, Xu Z et al (2023) General inverse kinematics method for 7-DOF offset manipulators based on arm angle parameterization. Acta Astronautica 202:263–277

Mirjalili S, Mirjalili S (2019) Genetic algorithm. In: Theory and applications, evolutionary algorithms and neural networks, pp. 43–55

Marini F, Walczak B (2015) Particle swarm optimization (PSO). A tutorial. Chemom Intell Lab Syst 149:153–165

Rezaei H, Bozorg-Haddad O, Chu X (2018) Grey wolf optimization (GWO) algorithm. In: Advanced optimization by nature-inspired algorithms, pp 81–91

Mirjalili S, Lewis A (2016) The whale optimization algorithm. Adv Eng Softw 95:51–67

Karaboga D (2010) Artificial bee colony algorithm. scholarpedia 5(3):6915

Funding

The authors declare that no funds, grants, or other support were received during the preparation of this manuscript.

Author information

Authors and Affiliations

Contributions

MK was involved in exploring and implementation of the proposed approach, and manuscript writing. VKY contributed in conceptualization, finalizing the proposed approach and preparing the draft of manuscript. SS helped in editing and improving the manuscript text. All authors have read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors have no relevant financial or non-financial interests to disclose.

Ethics approval

Not applicable.

Consent to participate

All applicable institutional guidelines were followed.

Consent for publication

Informed consent was obtained from all the co-authors of this publication.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kaur, M., Yanumula, V.K. & Sondhi, S. Trajectory planning and inverse kinematics solution of Kuka robot using COA along with pick and place application. Intel Serv Robotics 17, 289–302 (2024). https://doi.org/10.1007/s11370-023-00501-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11370-023-00501-6