Abstract

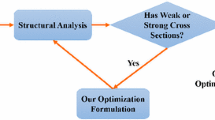

3D printing has become popular and has been widely used in various applications in recent years. More and more home users have motivation to design their own models and then fabricate them using 3D printers. However, the printed objects may have some structural or stress defects as the users may be lack of knowledge on stress analysis on 3D models. In this paper, we present an approach to help users analyze a model’s structural strength while designing its shape. We adopt sectional structural analysis instead of conventional FEM (Finite Element Method) analysis which is computationally expensive. Based on sectional structural analysis, our approach imports skeletons to assist in integrating mesh designing, strength computing and mesh correction well. Skeletons can also guide sections building and load calculation for analysis. For weak regions with high stress over a threshold value in the model from analysis result, our system corrects them by scaling the corresponding bones of skeleton so as to make these regions stiff enough. A number of experiments have demonstrated the applicability and practicability of our approach.

Similar content being viewed by others

Explore related subjects

Discover the latest articles and news from researchers in related subjects, suggested using machine learning.References

Stava O, Vanek J, Benes B, Carr N, Měch R. Stress relief: Improving structural strength of 3D printable objects. ACM Transactions on Graphics, 2012, 31(4): 48:1–48:11.

Zhou Q, Panetta J, Zorin D. Worst-case structural analysis. ACM Transactions on Graphics, 2013, 32(4): 137:1–137:12.

Umetani N, Schmidt R. Cross-sectional structural analysis for 3D printing optimization. In Proc. SIGGRAPH Asia Technical Briefs, November 2013, pp.5:1–5:4.

Prévost R, Whiting E, Lefebvre S, Sorkine-Hornung O. Make it stand: Balancing shapes for 3D fabrication. ACM Transactions on Graphics, 2013, 32(4): 81:1–81:10.

Bächer M, Whiting E, Bickel B, Sorkine-Hornung O. Spinit: Optimizing moment of inertia for spinnable objects. ACM Transactions on Graphics, 2014, 33(4): 96:1–96:10.

Bickel B, Bächer M, Otaduy M A, Lee H R, Pfister H, Gross M, Matusik W. Design and fabrication of materials with desired deformation behavior. ACM Transactions on Graphics, 2010, 29(4): 63:1–63:10.

Xie Y, Xu W, Yang Y, Guo X, Zhou K. Agile structural analysis for fabrication-aware shape editing. Computer Aided Geometric Design, 2015, 35/36: 163–179.

Hao J, Fang L, Williams R E. An efficient curvature-based partitioning of large-scale STL models. Rapid Prototyping Journal, 2011, 17(2): 116–127.

Luo L, Baran I, Rusinkiewicz S, Matusik W. Chopper: Partitioning models into 3D-printable parts. ACM Transactions on Graphics, 2012, 31(6): 129:1–129:10.

Wang W, Wang T Y, Yang Z, Liu L, Tong X, Tong W, Deng J, Chen F, Liu X. Cost-effective printing of 3D objects with skin-frame structures. ACM Transactions on Graphics, 2013, 32(6): 177:1–177:10.

Lu L, Sharf A, Zhao H, Wei Y, Fan Q, Chen X, Savoye Y, Tu C, Cohen-Or D, Chen B. Build-to-last: Strength to weight 3D printed objects. ACM Transactions on Graphics, 2014, 33(4): 97:1–97:10.

Zhang X, Xia Y, Wang J, Yang Z, Tu C, Wang W. Medial axis tree — An internal supporting structure for 3D printing. Computer Aided Geometric Design, 2015, 35(c): 149–162.

Telea A, Jalba A. Voxel-based assessment of printability of 3D shapes. In Proc. the 10th International Conference on Mathematical Morphology and Its Applications to Image and Signal Processing, July 2011, pp.393-404.

Hašan M, Fuchs M, Matusik W, Pfister H, Rusinkiewicz S. Physical reproduction of materials with specified subsurface scattering. ACM Transactions on Graphics, 2010, 29(4): 61:1–61:10.

Dong Y, Wang J, Pellacihi F, Tong X, Guo B. Fabricating spatially-varying subsurface scattering. ACM Transactions on Graphics, 2010, 29(4): 153:1–153:10.

Papas M, Regg C, Jarosz W, Bickel B, Jackson P, Matusik W, Marschner S, Gross M. Fabricating translucent materials using continuous pigment mixtures. ACM Transactions on Graphics, 2013, 32(4): 146:1–146:12.

Chen D, Levin D I, Didyk P, Sitthi-Amorn P, Matusik W. Spec2Fab: A reducer-tuner model for translating specifications to 3D prints. ACM Transactions on Graphics, 2013, 32(4): 135:1–135:10.

Weyrich T, Peers P, Matusik W, Rusinkiewicz S. Fabricating microgeometry for custom surface reflectance. ACM Transactions on Graphics, 2009, 28(3): 32:1–32:6.

Levin A, Glasner D, Xiong Y, Durand F, Freeman W, Matusik W, Zickler T. Fabricating BRDFs at high spatial resolution using wave optics. ACM Transactions on Graphics, 2013, 32(4): 144:1–144:13.

Matusik W, Ajdin B, Gu J, Lawrence J, Lensch H, Pellacini F, Rusinkiewicz S. Printing spatially-varying reflectance. ACM Transactions on Graphics, 2009, 28(5): 128:1–128:10.

Dong Y, Tong X, Pellacini F, Guo B. Printing spatiallyvarying reflectance for reproducing HDR images. ACM Transactions on Graphics, 2012, 31(4): 40:1–40:8.

Malzbender T, Samadani R, Scher S, Crume A, Dunn D, Davis J. Printing reflectance functions. ACM Transactions on Graphics, 2012, 31(3): 20:1–20:11.

Lan Y, Dong Y, Pellacini F, Tong X. Bi-scale appearance fabrication. ACM Transactions on Graphics, 2013, 32(4): 145:1–145:12.

Vidimče K, Wang S P, Ragan-Kelley J, Matusik W. Open- Fab: A programmable pipeline for multi-material fabrication. ACM Transactions on Graphics, 2013, 32(4): 136:1-136:11.

Song P, Fu C, Cohen-Or D. Recursive interlocking puzzles. ACM Transactions on Graphics, 2012, 31(6): 128:1–128:10.

Xin S, Lai C, Fu C, Wong T, He Y, Cohen-Or D. Making burr puzzles from 3D models. ACM Transactions on Graphics, 2011, 30(4): 97:1–97:8.

Coros S, Thomaszewski B, Noris G, Sueda S, Forberg M, Sumner R W, Matusik W, Bickel B. Computational design of mechanical characters. ACM Transactions on Graphics, 2013, 32(4): 83:1–83:12.

Zhu L, Xu W, Snyder J, Liu Y, Wang G, Guo B. Motionguided mechanical toy modeling. ACM Transactions on Graphics, 2012, 31(6): 127:1–127:10.

Ceylan D, Li W, Mitra N J, Agrawala M, Pauly M. Designing and fabricating mechanical automata from mocap sequences. ACM Transactions on Graphics, 2013, 32(6): 186:1–186:11.

Bächer M, Bickel B, James D L, Pfister H. Fabricating articulated characters from skinned meshes. ACM Transactions on Graphics, 2012, 31(4): 47:1–47:9.

Cali J, Calian D A, Amati C, Kleinberger R, Steed A, Kautz J, Weyrich T. 3D-printing of non-assembly, articulated models. ACM Transactions on Graphics, 2012, 31(6): 130:1–130:8.

Chen Y, Chen Z. Joint analysis in rapid fabrication of nonassembly mechanisms. Rapid Prototyping Journal, 2011, 17(6): 408–417.

Su X, Yang Y, Wang D, Chen Y. Digital assembly and direct fabrication of mechanism based on selective laser melting. Rapid Prototyping Journal, 2013, 19(3): 166–172.

Cornea N D, Silver D, Min P. Curve-skeleton properties, applications, and algorithms. IEEE Transactions on Visualization and Computer Graphics, 2007, 13(3): 530–548.

Au O K C, Tai C L, Chu H K, Cohen-Or D, Lee T Y. Skeleton extraction by mesh contraction. ACM Transactions on Graphics, 2008, 27(3): 44:1–44:10.

Chuang M, Kazhdan M. Fast mean-curvature flow via finiteelements tracking. Computer Graphics Forum, 2011, 30(6): 1750–1760.

Tagliasacchi A, Alhashim I, Olson M, Zhang H. Mean curvature skeletons. Computer Graphics Forum, 2012, 31(5): 1735–1744.

Jiang W, Xu K, Cheng Z Q, Martin R R, Dang G. Curve skeleton extraction by coupled graph contraction and surface clustering. Graphical Models, 2013, 75(3): 137–148.

Dey T K, Sun J. Defining and computing curve-skeletons with medial geodesic function. In Proc. the 4th Symposium on Geometry Processing, June 2006, pp.143-152.

Hilaga M, Shinagawa Y, Kohmura T, Kunii T L. Topology matching for fully automatic similarity estimation of 3D shapes. In Proc. the 28th Annual Conference on Computer Graphics and Interactive Techniques, Aug. 2001, pp.203-212.

Katz S, Tal A. Hierarchical mesh decomposition using fuzzy clustering and cuts. ACM Transactions on Graphics, 2003, 22(3): 954–961.

Sharf A, Lewiner T, Shamir A, Kobbelt L. On-the-fly curveskeleton computation for 3D shapes. Computer Graphics Forum, 2007, 26(3): 323–328.

Li G, Liu L, Zheng H, Mitra N J. Analysis, reconstruction and manipulation using arterial snakes. ACM Transactions on Graphics, 2010, 29(6): 152:1–152:10.

Cao J, Tagliasacchi A, Olson M, Zhang H, Su Z. Point cloud skeletons via Laplacian based contraction. In Proc. International Conference on Shape Modeling and Applications, June 2010, pp.187-197.

Livny Y, Yan F, Olson M, Chen B, Zhang H, El-Sana J. Automatic reconstruction of tree skeletal structures from point clouds. ACM Transactions on Graphics, 2010, 29(6): 151:1–151:8.

Tagliasacchi A, Zhang H, Cohen-Or D. Curve skeleton extraction from incomplete point cloud. ACM Transactions on Graphics, 2009, 28(3): 71:1–71:9.

Bucksch A, Lindenbergh R, Menenti M. SkelTre. The Visual Computer: International Journal of Computer Graphics, 2010, 26(10): 1283–1300.

Natali M, Biasotti S, Patanè G, Falcidieno B. Graph-based representations of point clouds. Graphical Models, 2011, 73(5): 151–164.

Baran I, Popović J. Automatic rigging and animation of 3D characters. ACM Transactions on Graphics, 2007, 26(3): 72:1–72:8.

Beer F P, Jr. Russell Johnston E, DeWolf J T, Mazurek D F. Mechanics of Materials (6th edition). New York: McGraw-Hill, 2012.

Author information

Authors and Affiliations

Corresponding author

Additional information

Special Section of CVM 2016

This work was supported by the National Natural Science Foundation of China under Grant Nos. 61222206 and 11526212, the 100 Talents Project of the Chinese Academy of Sciences, the Science and Technology Project of Henan Province of China under Grant No. 162102310090, and the Key Scientific Research Projects of the Higher Education Institutions of Henan Province of China under Grant No. 16A520011.

Rights and permissions

About this article

Cite this article

Xu, WP., Li, W. & Liu, LG. Skeleton-Sectional Structural Analysis for 3D Printing. J. Comput. Sci. Technol. 31, 439–449 (2016). https://doi.org/10.1007/s11390-016-1638-2

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11390-016-1638-2