Abstract

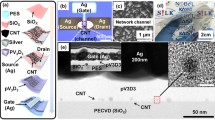

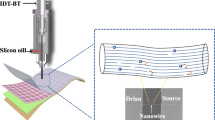

High-performance logic circuits fabricated on flexible or unconventional substrates have become a necessity for several new applications. Generally, compared to those fabricated on more rigid substrates, printed, large-area, and flexible thin film transistors (TFTs) are prone to under-performance, which severely limits their practical value. The realization of printed flexible macroelectronics requires advancements in material science and novel fabricating techniques. In this study, using a fast printing process, we manufacture liquid metal-carbon nanotube TFTs on a thin polyethylene terephthalate substrate. These flexible TFTs (p-type) exhibit enhance stability and flexibility, carrier mobility (10.61 cm2V−1s−1), and transconductance (0.88 µS). Furthermore, we realize dependable n-type and ambipolar transistors based on liquid metals with charge transport efficiencies that are comparable to our p-type counterparts, thus providing a foundation for manufacturing integrated circuits and complementary logic gates on flexible substrates. This study shows the positive progress of liquid metal printing-enabled functional devices and discusses the possibility of practical applications; moreover, it sets the foundation for printed high-performance and large-area flexible liquid metal electronics.

Similar content being viewed by others

References

Myny K. The development of flexible integrated circuits based on thin-film transistors. Nat Electron, 2018, 1: 30–39

Di C A, Liu Y, Yu G, et al. Interface engineering: an effective approach toward high-performance organic field-effect transistors. Acc Chem Res, 2009, 42: 1573–1583

Wang H L, Wei P, Li Y X, et al. Tuning the threshold voltage of carbon nanotube transistors by n-type molecular doping for robust and flexible complementary circuits. PNAS, 2014, 111: 4776–4781

Geier M L, Prabhumirashi P L, McMorrow J J, et al. Subnanowatt carbon nanotube complementary logic enabled by threshold voltage control. Nano Lett, 2013, 13: 4810–4814

Kim B, Jang S, Geier M L, et al. High-speed, inkjet-printed carbon nanotube/zinc tin oxide hybrid complementary ring oscillators. Nano Lett, 2014, 14: 3683–3687

Ding L, Zhang Z, Liang S, et al. CMOS-based carbon nanotube pass-transistor logic integrated circuits. Nat Commun, 2012, 3: 677

Gao P, Zou J, Li H, et al. Complementary logic gate arrays based on carbon nanotube network transistors. Small, 2013, 9: 813–819

Kang B R, Yu W J, Kim K K, et al. Restorable type conversion of carbon nanotube transistor using pyrolytically controlled antioxidizing photosynthesis coenzyme. Adv Funct Mater, 2009, 19: 2553–2559

Kim S M, Jang J H, Kim K K, et al. Reduction-controlled viologen in bisolvent as an environmentally stable n-type dopant for carbon nanotubes. J Am Chem Soc, 2009, 131: 327–331

Choi Y, Kan J, Secor E B, et al. Capacitively coupled hybrid ion gel and carbon nanotube thin-film transistors for low voltage flexible logic circuits. Adv Funct Mater, 2018, 28: 1802610

Hong K, Kim Y H, Kim S H, et al. Aerosol jet printed, sub-2 V complementary circuits constructed from P- and N-type electrolyte gated transistors. Adv Mater, 2014, 26: 7032–7037

Ha M, Seo J W T, Prabhumirashi P L, et al. Aerosol jet printed, low voltage, electrolyte gated carbon nanotube ring oscillators with sub-5 µs stage delays. Nano Lett, 2013, 13: 954–960

Chen H, Cao Y, Zhang J, et al. Large-scale complementary macroelectronics using hybrid integration of carbon nanotubes and IGZO thin-film transistors. Nat Commun, 2014, 5: 4097

Honda W, Harada S, Ishida S, et al. High-performance, mechanically flexible, and vertically integrated 3D carbon nanotube and InGaZnO complementary circuits with a temperature sensor. Adv Mater, 2015, 27: 4674–4680

Han S J, Tang J, Kumar B, et al. High-speed logic integrated circuits with solution-processed self-assembled carbon nanotubes. Nat Nanotech, 2017, 12: 861–865

Plevachuk Y, Sklyarchuk V, Yakymovych A, et al. Electrical conductivity and viscosity of liquid Sn-Sb-Cu alloys. J Mater Sci-Mater Electron, 2011, 22: 631–638

Zheng Y, He Z, Gao Y, et al. Direct desktop printed-circuits-on-paper flexible electronics. Sci Rep, 2013, 3: 1786

Liu F, Yu Y, Yi L, et al. Liquid metal as reconnection agent for peripheral nerve injury. Sci Bull, 2016, 61: 939–947

Wang L, Liu J. Compatible hybrid 3D printing of metal and nonmetal inks for direct manufacture of end functional devices. Sci China Technol Sci, 2014, 57: 2089–2095

Guo C, Yu Y, Liu J. Rapidly patterning conductive components on skin substrates as physiological testing devices via liquid metal spraying and pre-designed mask. J Mater Chem B, 2014, 2: 5739–5745

Jeong S H, Hagman A, Hjort K, et al. Liquid alloy printing of microfluidic stretchable electronics. Lab Chip, 2012, 12: 4657–4664

Yu Y, Zhang J, Liu J. Biomedical implementation of liquid metal ink as drawable ECG electrode and skin circuit. PLoS ONE, 2013, 8: e58771

Wang Q, Yu Y, Yang J, et al. Fast fabrication of flexible functional circuits based on liquid metal dual-trans printing. Adv Mater, 2015, 27: 7109–7116

Matsuzaki R, Tabayashi K. Highly stretchable, global, and distributed local strain sensing line using gainsn electrodes for wearable electronics. Adv Funct Mater, 2015, 25: 3806–3813

Krupenkin T, Taylor J A. Reverse electrowetting as a new approach to high-power energy harvesting. Nat Commun, 2011, 2: 448

Zhang Q, Gao Y, Liu J. Atomized spraying of liquid metal droplets on desired substrate surfaces as a generalized way for ubiquitous printed electronics. Appl Phys A, 2014, 116: 1091–1097

Zhang Q, Zheng Y, Liu J. Direct writing of electronics based on alloy and metal (DREAM) ink: a newly emerging area and its impact on energy, environment and health sciences. Front Energy, 2012, 6: 311–340

Kim J, Ahmed T, Nili H, et al. A physical unclonable function with redox-based nanoionic resistive memory. IEEE Trans Inform Forensic Secur, 2018, 13: 437–448

Hu Z, Comeras J M M L, Park H, et al. Physically unclonable cryptographic primitives using self-assembled carbon nanotubes. Nat Nanotech, 2016, 11: 559–565

Xu F, Zhu Y. Highly conductive and stretchable silver nanowire conductors. Adv Mater, 2012, 24: 5117–5122

Kim Y, Zhu J, Yeom B, et al. Stretchable nanoparticle conductors with self-organized conductive pathways. Nature, 2013, 500: 59–63

Park M, Im J, Shin M, et al. Highly stretchable electric circuits from a composite material of silver nanoparticles and elastomeric fibres. Nat Nanotech, 2012, 7: 803–809

Matsuhisa N, Kaltenbrunner M, Yokota T, et al. Printable elastic conductors with a high conductivity for electronic textile applications. Nat Commun, 2015, 6: 7461

Stoyanov H, Kollosche M, Risse S, et al. Soft conductive elastomer materials for stretchable electronics and voltage controlled artificial muscles. Adv Mater, 2013, 25: 578–583

Chun K Y, Oh Y, Rho J, et al. Highly conductive, printable and stretchable composite films of carbon nanotubes and silver. Nat Nanotech, 2010, 5: 853–857

Sekitani T, Nakajima H, Maeda H, et al. Stretchable active-matrix organic light-emitting diode display using printable elastic conductors. Nat Mater, 2009, 8: 494–499

Gelinck G H, Huitema H E A, van Veenendaal E, et al. Flexible active-matrix displays and shift registers based on solution-processed organic transistors. Nat Mater, 2004, 3: 106–110

Gamota D R, Brazis P, Kalyanasundaram K, et al. Printed Organic and Molecular Electronics. New York: Springer Science & Business Media, 2013

Zheng Y, He Z Z, Yang J, et al. Personal electronics printing via tapping mode composite liquid metal ink delivery and adhesion mechanism. Sci Rep, 2015, 4: 4588

Cao Q, Xia M, Kocabas C, et al. Gate capacitance coupling of singled-walled carbon nanotube thin-film transistors. Appl Phys Lett, 2007, 90: 023516

Ante F, K¨alblein D, Zaki T, et al. Contact resistance and megahertz operation of aggressively scaled organic transistors. Small, 2012, 8: 73–79

Cao C, Andrews J B, Kumar A, et al. Improving contact interfaces in fully printed carbon nanotube thin-film transistors. ACS Nano, 2016, 10: 5221–5229

Okimoto H, Takenobu T, Yanagi K, et al. Tunable carbon nanotube thin-film transistors produced exclusively via inkjet printing. Adv Mater, 2010, 22: 3981–3986

Andrews J B, Mondal K, Neumann T V, et al. Patterned liquid metal contacts for printed carbon nanotube transistors. ACS Nano, 2018, 12: 5482–5488

Liu C, Xu Y, Li Y, et al. Critical impact of gate dielectric interfaces on the contact resistance of high-performance organic field-effect transistors. J Phys Chem C, 2013, 117: 12337–12345

Yu M, Wan H, Cai L, et al. Fully printed flexible dual-gate carbon nanotube thin-film transistors with tunable ambipolar characteristics for complementary logic circuits. ACS Nano, 2018, 12: 11572–11578

Goh R G S, Bell J M, Motta N, et al. p-Channel, n-Channel and ambipolar field-effect transistors based on function-alized carbon nanotube networks. Superlattices Microst, 2009, 46: 347–356

Allard S, Forster M, Souharce B, et al. Organic semiconductors for solution-processable field-effect transistors (OFETs). Angew Chem Int Ed, 2008, 47: 4070–4098

Sirringhaus H. Device physics of solution-processed organic field-effect transistors. Adv Mater, 2005, 17: 2411–2425

Sun Y, Rogers J A. Inorganic semiconductors for flexible electronics. Adv Mater, 2007, 19: 1897–1916

Yan H, Chen Z, Zheng Y, et al. A high-mobility electron-transporting polymer for printed transistors. Nature, 2009, 457: 679–686

Chortos A, Lim J, To J W F, et al. Highly stretchable transistors using a microcracked organic semiconductor. Adv Mater, 2014, 26: 4253–4259

Kang S J, Kocabas C, Ozel T, et al. High-performance electronics using dense, perfectly aligned arrays of single-walled carbon nanotubes. Nat Nanotech, 2007, 2: 230–236

L´eonard F, Tersoff J. Novel length scales in nanotube devices. Phys Rev Lett, 1999, 83: 5174–5177

Yang Y, Ding L, Han J, et al. High-performance complementary transistors and medium-scale integrated circuits based on carbon nanotube thin films. ACS Nano, 2017, 11: 4124–4132

Zhao Y, Li Q, Xiao X, et al. Three-dimensional flexible complementary metal-oxide-semiconductor logic circuits based on two-layer stacks of single-walled carbon nanotube networks. ACS Nano, 2016, 10: 2193–2202

Geier M L, McMorrow J J, Xu W, et al. Solution-processed carbon nanotube thin-film complementary static random access memory. Nat Nanotech, 2015, 10: 944–948

Ha T J, Chen K, Chuang S, et al. Highly uniform and stable n-type carbon nanotube transistors by using positively charged silicon nitride thin films. Nano Lett, 2015, 15: 392–397

Li G, Li Q, Jin Y, et al. Fabrication of air-stable n-type carbon nanotube thin-film transistors on flexible substrates using bilayer dielectrics. Nanoscale, 2015, 7: 17693–17701

Ng T N, Daniel J H, Sambandan S, et al. Gate bias stress effects due to polymer gate dielectrics in organic thin-film transistors. J Appl Phys, 2008, 103: 044506

Richards T, Sirringhaus H. Bias-stress induced contact and channel degradation in staggered and coplanar organic field-effect transistors. Appl Phys Lett, 2008, 92: 023512

Salleo A, Street R A. Light-induced bias stress reversal in polyfluorene thin-film transistors. J Appl Phys, 2003, 94: 471–479

Acknowledgements

This work was partially supported by National Natural Science Foundation of China Key Project (Grant No. 91748206), Dean’s Research Funding and the Frontier Project of the Chinese Academy of Sciences. Qian LI acknowledges the support by China Postdoctoral Science Foundation (Grant No. 2018M641485). The authors are grateful for the support of Beijing DREAM Ink Technologies Co., Ltd.

Author information

Authors and Affiliations

Corresponding author

Additional information

Supporting information Figures

S1–S8, Tables S1 and S2. The supporting information is available online at info.scichina.com and link.springer.com. The supporting materials are published as submitted, without typesetting or editing. The responsibility for scientific accuracy and content remains entirely with the authors.

Rights and permissions

About this article

Cite this article

Li, Q., Lin, J., Liu, T. et al. Printed flexible thin-film transistors based on different types of modified liquid metal with good mobility. Sci. China Inf. Sci. 62, 202403 (2019). https://doi.org/10.1007/s11432-019-9918-4

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11432-019-9918-4