Abstract

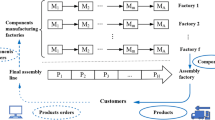

In this paper, we investigate a manufacturer selection and composition problem for Distributed Virtual Manufacturing Network (DVMN) with order acceptance and scheduling of deteriorating jobs, where potential manufacturers include proprietary plants and outsourced co-manufacturers. In such a problem, at the beginning of planning horizon, a manufacturing company (MC) receives a series of order requests from its customers. Due to the limited production capacity, the MC is not able to fulfill all the orders requested by the customers on time. To satisfy the order demand as much as possible, one of the MC’s choices is to establish a collaborative manufacturing platform (i.e., DVMN) that leverages the advantages of a social manufacturing network to expand their production capabilities. However, the increase in production capacity does not mean that all orders from the customers are able to be accepted and produced. In fact, standing at the profit-maximizing point of view, the order requests that do not bring profits to the company need to be rejected at the beginning of planning horizon. For the accepted orders, the MC will produce a part of them by its plants in the DVMN, and the remaining orders will be outsourced to other co-manufacturers in the DVMN. Based on some structural properties, we develop a novel Reduced Variable Neighborhood Search (RVNS) algorithm incorporated multiple random mutations neighborhood structures (NSs-MRM) to determine the composition of the DVMN, and further determine which orders should be rejected, which accepted orders should be processed by the company-owned plants in the DVMN, and which accepted orders should be outsourced to the co-manufacturers in the DVMN. In particular, the processing sequence of the orders produced in the company-owned plants are also determined. Finally, a reasonable composition of the DVMN and corresponding order acceptance as well as order scheduling on each member of the DVMN are given. To evaluate the proposed algorithm, a series of computational experiments are conducted, and the experimental results show that the proposed algorithm outperforms other existing baseline algorithms in solving both small-scale and large-scale problem instances.

Similar content being viewed by others

References

Wu, S.H., Fuh, J.Y.H., Nee, A.Y.C.: Concurrent process planning and scheduling in distributed virtual manufacturing. IIE Trans. 34(1), 77–89 (2002)

Lau, H.C.W., Wong, E.T.T.: Partner selection and information infrastructure of a virtual enterprise network. Int. J. Comput. Integr. Manuf. 14(2), 186–193 (2001)

Viswanadham, N., Gaonkar, R.S.: Partner selection and synchronized planning in dynamic manufacturing networks. IEEE Trans. Robot. Autom. 19(1), 117–130 (2003)

Dotoli, Mariagrazia, et al.: Design and optimization of integrated e-supply chain for agile and environmentally conscious manufacturing. IEEE Trans. Syst. Man Cybern. Part A Syst. Hum. 36(1), 62–75 (2006)

Yang, S., Wang, J., Shi, L., et al.: Engineering management for high-end equipment intelligent manufacturing. Front. Eng 5(4), 420–450 (2018)

Papakostas, N., et al.: On the configuration and planning of dynamic manufacturing networks. In: Robust Manufacturing Control. Springer, Berlin, Heidelberg, pp. 247–258 (2013)

Defregger, F., Kuhn, H.: Markov decision models for order acceptance/rejection problems. In: Fifth International Conference on Analysis of Manufacturing Systems—Production Management, pp. 265–272 (2005)

Lin, Shih-Wei, Ying, Kuo-Ching: Order acceptance and scheduling to maximize total net revenue in permutation flowshops with weighted tardiness. Appl. Soft Comput. 30, 462–474 (2015)

Rahman, Humyun Fuad, Sarker, Ruhul, Essam, Daryl: A real-time order acceptance and scheduling approach for permutation flow shop problems. Eur. J. Oper. Res. 247(2), 488–503 (2015)

Xu, Lei, Wang, Qian, Huang, Simin: Dynamic order acceptance and scheduling problem with sequence-dependent setup time. Int. J. Prod. Res. 53(19), 5797–5808 (2015)

Chaurasia, Sachchida Nand, Singh, Alok: Hybrid evolutionary approaches for the single machine order acceptance and scheduling problem. Appl. Soft Comput. 52, 725–747 (2017)

Ou, Jinwen, Zhong, Xueling: Order acceptance and scheduling with consideration of service level. Ann. Oper. Res. 248(1–2), 429–447 (2017)

Ou, Jinwen, Zhong, Xueling: Bicriteria order acceptance and scheduling with consideration of fill rate. Eur. J. Oper. Res. 262(3), 904–907 (2017)

Kong, Min, et al.: Parallel-batching scheduling of deteriorating jobs with non-identical sizes and rejection on a single machine. Optim. Lett. (2019). https://doi.org/10.1007/s11590-019-01389-x

Lee, Ik Sun, Sung, Chang Sup: Single machine scheduling with outsourcing allowed. Int. J. Prod. Econ. 111(2), 623–634 (2008)

Neto, R.F.T., Godinho Filho, M., Da Silva, F.M.: An ant colony optimization approach for the parallel machine scheduling problem with outsourcing allowed. J. Intell. Manuf. 26(3), 527–538 (2015)

Liu, Xufei, Chung, Tsui-Ping: An outsourcing-scheduling problem in a two-stage supply chain via improved immunoglobulin-based artificial immune system. Comput. Ind. Eng. 113, 819–830 (2017)

Yang, D.-L., Kuo, W.-H.: Some scheduling problems with deteriorating jobs and learning effects. Comput. Ind. Eng. 58(1), 25–28 (2010)

Ji, Min, Edwin Cheng, T.C.: Parallel-machine scheduling of simple linear deteriorating jobs. Theor. Comput. Sci. 410(38–40), 3761–3768 (2009)

Hansen, Pierre, Mladenović, Nenad: Variable neighborhood search: principles and applications. Eur. J. Oper. Res. 130(3), 449–467 (2001)

Bean, James C.: Genetic algorithms and random keys for sequencing and optimization. ORSA J. Comput. 6(2), 154–160 (1994)

Nouiri, Maroua, et al.: An effective and distributed particle swarm optimization algorithm for flexible job-shop scheduling problem. J. Intell. Manuf. 29(3), 603–615 (2018)

Mahi, Mostafa, Baykan, Ömer Kaan, Kodaz, Halife: A new hybrid method based on particle swarm optimization, ant colony optimization and 3-opt algorithms for traveling salesman problem. Appl. Soft Comput. 30, 484–490 (2015)

Zudio, Anderson, et al.: BRKGA/VND hybrid algorithm for the classic three-dimensional bin packing problem. Electron. Notes Discrete Math. 66, 175–182 (2018)

Sevkli, M., Aydin, M.E.: A variable neighbourhood search algorithm for job shop scheduling problems. In: European Conference on Evolutionary Computation in Combinatorial Optimization. Springer, Berlin, Heidelberg (2006)

Sevkli, M., Uysal, H.: A modified variable neighborhood search for minimizing the makespan on identical parallel machines. In: 2009 International Conference on Computers & Industrial Engineering. IEEE (2009)

Chaves, Antonio Augusto, et al.: Hybrid method with CS and BRKGA applied to the minimization of tool switches problem. Comput. Oper. Res. 67, 174–183 (2016)

Zhou, Hongming, Pang, Jihong, Chen, Ping-Kuo, Chou, Fuh-Der: A modified particle swarm optimization algorithm for a batch-processing machine scheduling problem with arbitrary release times and non-identical job sizes. Comput. Ind. Eng. 123, 67–81 (2018)

Fan, Wenjuan, et al.: Serial-batching group scheduling with release times and the combined effects of deterioration and truncated job-dependent learning. J. Glob. Optim. 71(1), 147–163 (2018)

Wang, Ji-Bo, Lin, Lin, Shan, Feng: Single-machine group scheduling problems with deteriorating jobs. Int. J. Adv. Manuf. Technol. 39(7–8), 808–812 (2008)

Liao, B., et al.: Parallel-machine group scheduling with inclusive processing set restrictions, outsourcing option and serial-batching under the effect of step-deterioration. J. Glob. Optim (2018). https://doi.org/10.1007/s10898-018-0707-1

Acknowledgements

This work is supported by the National Natural Science Foundation of China (Nos. 71871080, 71601065, 71690235, 71501058, 71601060), and Innovative Research Groups of the National Natural Science Foundation of China (71521001), Anhui Province Natural Science Foundation (No. 1908085MG223), Base of Introducing Talents of Discipline to Universities for Optimization and Decision-making in the Manufacturing Process of Complex Product (111 project), the Project of Key Research Institute of Humanities and Social Science in University of Anhui Province, Open Research Fund Program of Key Laboratory of Process Optimization and Intelligent Decision-making (Hefei University of Technology), Ministry of Education.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix

Appendix

The following lemmas are reported without detailed proof, since it can be derived from the basic mathematical method and has been frequently presented in the literature on the scheduling of deteriorating jobs [29,30,31].

Lemma 1

For any order assigned into any company-owned plant, such as \( o_{ijk} \left( {CP} \right) \) , the jobs in this order should be processed by the Shortest Normal Processing Time(SNPT) rule.

Proof

This Lemma can be proven by exchanging adjacent jobs, and we omit it. □

Without loss of generality, we assume that the indices of the jobs in any order satisfy the SNPT rule. That is, \( p_{ijk1} \left( {CP} \right) \le \cdots p_{ijkg} \left( {CP} \right) \cdots \le p_{{ijkn_{ijk} \left( {CP} \right)}} \left( {CP} \right) \). In Lemma 2, we give the completion time of \( o_{ijk} \left( {CP} \right) \) if it starts at time \( T \).

Lemma 2

For any order assigned into any company-owned plant, such as \( o_{ijk} \left( {CP} \right) \) , the completion time of \( o_{ijk} \left( {CP} \right) \) is

Proof

This Lemma can be proven easily by mathematical induction method, and we omit it. □

Lemma 3

For any company-owned plant, such as \( CP_{ij} \) , all the orders assigned into this plant should be processed by the non-increasing order of \( \rho (o_{ijk} \left( {CP} \right)) \) , where the \( \rho (o_{ijk} \left( {CP} \right)) \) is

Proof

This proof is simple, and we omit it. □

Without loss of generality, we assume that the indices of orders in any plant satisfy the property displayed in Lemma 3. Then, the \( C_{ij} \left( {CP} \right) \) can be calculated in Lemma 4.

Lemma 4

For any company-owned plant, such as \( CP_{ij} \), the completion time the last order of \( CP_{ij} \) is

where \( \mathop \sum \nolimits_{{k = n_{ij} \left( {CP} \right) + 1}}^{{n_{ij} \left( {CP} \right)}} n_{ijk} \left( {CP} \right) = 0 \).

Proof

This Lemma can be proven easily by mathematical induction method, and we omit it. □

Rights and permissions

About this article

Cite this article

Kong, M., Zhou, J., Pei, J. et al. A modified variable neighborhood search algorithm for manufacturer selection and order acceptance in distributed virtual manufacturing network. Optim Lett 16, 117–135 (2022). https://doi.org/10.1007/s11590-019-01450-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11590-019-01450-9