Abstract

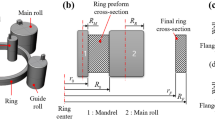

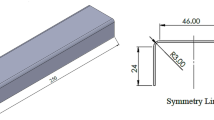

Regarding the increasing demand on annular components with complex geometries, a flexible process has been developed at the IBF to profile sleeve shaped rings. Unlike processes using grooved tools, here diverse contours can be realized on the inner surface using one “universal” tool. By extending the tool kinematics and developing an adequate forming strategy the general feasibility of the process has been shown on a bench scaled model ring rolling rig using a wax based model material. Parameters such as ring/tool geometry and roller feed strategy were detected as having an effect on material flow resistance in the rolling and transverse directions. Expressing them by geometric ratios, the material flow distribution could be determined in numerous experiments and quantified by a newly-defined extension coefficient with a certainty of 95%. This achievement enables us to predict the material flow in axial and tangential directions to manufacture complex geometries reproducibly.

Similar content being viewed by others

References

Böhmer C, Wen T, Kopp R (2003) Neues flexibles Verfahren für das einseitige axiale Profilieren von Ringen durch Walzen. Stahl Eisen 123(4):63–68

Omori S et al (1984) Experiment on the roll forming for disk-shaped blanks. In: Proceedings of the 3rd international conference on rotary metalworking processes, Kyoto, Japan, pp 311–320

Böhlke P (2005) Entwicklung eines Walzprozesses zur Erzeugung von Bändern mit definiertem Querschnittsprofil. Dissertation, RWTH Aachen

Pentleit A (2004) Modellgestützte Erweiterung der Prozessgrenzen zum Walzen außenprofilierter Ringe. Dissertation, Ruhr-Universität-Bochum

Tani K, Ishigai S, Sato T (2005) The evolution of near-net-shap ring-rolling processes for large rings made of Ti–6Al-4V. Kobelco Technol Rev 26:43–48

Kopp R, Wiegels H, Pöll H-A (1992) Grundlagenuntersuchungen zum Walzen von Ringen mit profiliertem Querschnitt. Abschlussbericht zum DFG-Forschungsvorhaben Ko 579/29. Institut für Bildsame Formgebung, RWTH Aachen

Allwood J, Tekkaya E, Stanistreet T (2005) The development of ring rolling technology. Steel Res Int 76:111–120

Koppers U (1993) Flexibles Walzen von Ringen mit Profilquerschnitt–Anwendungen. Umformtechnik 27(1):36–38

Mauk PJ, Kopp R (1982) Spread under hot rolling. Kalibreur Heft 37:61–68

Koppers U (1986) Geometrie, Kinematik und Statik beim Walzen von Ringen mit Rechteckquerschnitten. RWTH Aachen, Aachen

Hülshorst T, Wiegels H, Wang H, Kopp R (1999) Experimentelle simulation mit einem flexiblen Modell-Ringwalzwerk. Stahl Eisen 119(11):65–70

Boucly P, Oudin J, Ravalard Y (1988) Simulation of ring rolling with new wax-based model material on a flexible experimental machine. J Mech Work Technol 16:119–143

Acknowledgments

This project was carried out with the thankful help and support of the German Research Foundation (DFG).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tiedemann, I., Hirt, G., Kopp, R. et al. Material flow determination for radial flexible profile ring rolling. Prod. Eng. Res. Devel. 1, 227–232 (2007). https://doi.org/10.1007/s11740-007-0030-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11740-007-0030-z