Abstract

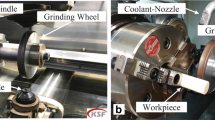

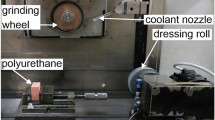

Metal bonded grinding tools offer a remarkable potential for micro grinding because of their favorable wear behavior. However, metal bonded grinding tools, especially dicing blades, are hard to dress by conventional dressing methods. Electro contact discharge dressing, which is presented in this paper, is a numerically controlled dressing process offering the possibility to create the geometry and topography of the grinding wheel simultaneously at negligible dressing forces. The power of an electric circuit thermally removes the metal bond of the grinding wheel during the dressing process. The quality of the created profiles and the influence of the dressing parameters on the specific material removal rate of the grinding tool as well as the wear of the electrode are investigated at fine-grained grinding wheels.

Similar content being viewed by others

References

Wenda A (2002) Schleifen von Mikrostrukturen in sprödharten Werkstoffen, Dr.-Ing. Diss., Braunschweig Technical University

Hoffmeister H-W, Hlavac M (2004) Dressing of micro-grinding wheels. In: Proceedings of the 4th euspen international conference. Glasgow, pp. 135–136

König W (1989) Fertigungsverfahren Band 2—Schleifen, Honen, Läppen. VDI-Verlag, Düsseldorf

Xie J, Tang Y, Tamaki J (2006) A study on surface generation of metal-bonded diamond grinding wheel dressed by electro-contact discharge. Key Eng Mater 304/305:76–80

Tamaki J, Kitagawa T (1992) Electrocontact discharge dressing of metal-bonded diamond wheel (Part 1). Int J Jpn Soc Precision Eng 26(4):284–289

Tamaki J, Kitagawa T (1992) Electrocontact discharge dressing of metal-bonded diamond wheel (Part 2). Int J Jpn Soc Precision Eng 28(4):334–339

Denkena B, Becker JC, Reichstein M, Meer M. van der (2004) Kontakterosives Konditionieren, Jahrbuch Schleifen, Honen, Läppen, Polieren, Ausgabe 61, pp 189–197

Xie J, Tamaki J, Kubo A, Iyama T (2001) Application of Electro-contact Discharge Dressing to a Fine-grained Diamond Grinding Wheel. Seimitsu-k ogakkai-shi 67(11):1844–1849

Denkena B, Reichstein M, Hahmann D (2006) Electro Contact discharge dressing for micro-grinding. In: Proceedings of the 6th euspen international conference. Baden, pp 92-95

Wang Y, Zhou X, Hu D-J (2006) An experimental investigation of dry-electrical discharge assisted truing and dressing of metal bonded diamond wheel. Int J Mach Tools Manuf 46:333–342

Friemuth T, Dieterle A (1999) Schleifen hartstoffverstärkter keramischer Werkzeuge, VDI Verlag GmbH, Düsseldorf, Reihe 2, Nr. 510

Falkenberg Y (1997) Elektroerosives Schärfen von Bornitrid-schleifscheiben, Dr.-Ing. Diss., Hannover University

Acknowledgements

The results presented in this paper were funded by the German Research Foundation (DFG) within the SFB 516 B3.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Denkena, B., Reichstein, M. & Hahmann, D. Dressing of filigree fine-grained metal bonded grinding wheels. Prod. Eng. Res. Devel. 1, 239–243 (2007). https://doi.org/10.1007/s11740-007-0035-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11740-007-0035-7