Abstract

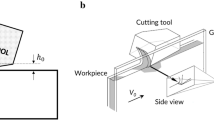

Microstructuring of mechanically and thermally highly stressed surfaces offers an innovative alternative for adjusting tribological properties and thus reducing friction losses and wear. At the Institute of Production Engineering and Machine Tools (IFW) functional surfaces are structured via cutting. This paper introduces to the basic principles of manufacturing microstructures in ductile materials foccussing cutting tool- and process-dimensioning. Scratch tests are carried out at planar surfaces to describe the basic chacacteristics when producing structures in micron range. Due to the small structure depths, size effects have to be considered. On this account, influences and interrelations of cutting edge microgeometry, material properties, as well as cutting parameters are investigated. In order to avoid further finishing operations, sharp structures with tolerable burr formation have to be achieved.

Similar content being viewed by others

References

Lindner H, Bermann HW, Brandenstein C, Lang A, Queitsch R, Reichsten S, Stengel E (2003) Precision processing of cast iron cylinder surfaces of combustion engines with UV-photons. University of Bayreuth

Golloch R, Merker GP, Kessen U, Brinkmann S (2004) Benefits of laser-structured cylinder liners for internal combustion engines. 14th international colloquium tribology, Technische Akademie Esslingen

Fischer S (2000) Fertigungssysteme zur spanenden Herstellung von Mikrostrukturen. Dissertation, RWTH Aachen

Bissaco G, Hansen HN, De Chiffre L (2006) Size effects on surface generation in micro milling of hardened tool steel. Annals of the CIRP, vol 55/1. Technical University of Denmark, pp 593–596

Quoteiro JC, Dias AM, Jawahir IS (2006) On the effects of residual stresses inducted by coated and uncoated cutting tools with finite edge radii in turning operations. Annals of the CIRP, vol 55/1. University of Coimbra Portugal, University of Kentucky USA, pp 111–116

Hüntrup V (2000) Untersuchungen zur Mikrostrukturierbarkeit von Stählen durch das Fertigungsverfahren Fräsen. Dissertation, Universität Karlsruhe

Schmidt J (1999) Mechanische und thermische Wirkungen beim Drehen gehärteter Stähle. Dissertation, Universität Hannover

Schmütz J (2002) Mikrobearbeitung duktiler Werkstoffe mit ultraschall-angeregten Diamantwerkzeugen. Dissertation, Universität Bremen

Riemer O (2001) Trennmechanismen und Oberflächenfeingestalt bei der Mikrozerspanung kristalliner und amorpher Werkstoffe. Dissertation, Universität Bremen

Denkena B, Tönshoff HK, Becker J, Bockhorst J, Hillmannn-Apmann, H (2003) The mechanisms of material separation at steel and concrete material. Euro PM2003, Universität Hannover

Giwerzew A (2003) Spanbildungsmechansimen und tribolo-gisches Prozessverhalten beim Schleifen mit niedrigen Schnittgeschwindigkeiten. Dissertation, Universität Bremen

Betz F (1971) Die Beeinflussung der Schnittflächenrauhigkeit durch die Mikrogestalt der Werkzeugschneide. Annals of the CIRP, vol 15/5, Technische Hochschule Zürich, pp 625–631

Schauer K (2006) Entwicklung von Hartmetallwerkzeugen für die Mikro-zerspanung mit definierter Schneide. Dissertation, Technische Universität Berlin

Author information

Authors and Affiliations

Corresponding author

Additional information

The investigations presented in this paper are supported by the German Research Foundation (DFG) within the project “Microstructuring of Thermomechanically High Stressed Surfaces”.

Rights and permissions

About this article

Cite this article

Denkena, B., Boehnke, D. & Kästner, J. Microstructuring of functional surfaces by means of cutting processes. Prod. Eng. Res. Devel. 2, 21–25 (2008). https://doi.org/10.1007/s11740-008-0079-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11740-008-0079-3