Abstract

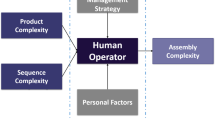

A key to solving the discrepancies of deterministic and static assembly sequences at manual work places is seen in situation-oriented and cognitive methodologies in assembly. These provide means for efficient and ergonomically feasible worker guidance. An accurate and detailed technique of adjusting the instructional content is seen as a prerequisite. In this context the authors present factors for a multi-dimensional measurement of the degree of detail and complexity of manual assembly tasks. It extends the concept and application of common systems of predetermined times. It includes dimensions of actual human performance and attention allocation, as well as learning effects based on the product and its reference levels. It is assumed that identifying global attributes that contribute to assembly difficulty will provide means for predicting assembly complexity more effectively.

Similar content being viewed by others

References

Wiendahl HP, ElMaraghy HA, Nyhuis P, Zäh MF, Wiendahl HH, Duffie N, Brieke M (2007) Changeable manufacturing–classification, design and operation. Ann CIRP 56(2):783–809

Zäh MF, Beetz M, Shea K, Reinhart G, Bender K, Lau C, Ostgathe M, Vogl W, Wiesbeck M, Engelhard M, Ertelt C, Ruehr T, Friedrich M, Herle S (2009) The cognitive factory. In: ElMaraghy HA (ed) Changeable and reconfigurable manufacturing systems. London, Springer

ElMaraghy WH, Urbanic RJ (2004) Assessment of manufacturing operational complexity. Ann CIRP 53(1):401–406

Jensen PL, Alting L (2006) Human factors in the management of production. Ann CIRP 55(1):457–460

Reinhart G, Patron C (2003) Integrating augmented reality in the assembly domain–fundamentals, benefits and applications. Ann CIRP 52(1):5–8

Zaeh M, Prasch M (2007) Systematic workplace and assembly redesign for aging workforces. J Prod Eng 1(1):57–64

Kjellberg A, Abestam L (1997) Human factor framework for analysis of an assembly work. Ann CIRP 46(1):377–380

Zäh M, Wiesbeck M, Wallhoff F, Stork S, Engstler F, Bannat A, Schubö A, Friesdorf F (2007) Kognitive Assistenzsysteme in der manuellen Montage. Wt Werkstattstechnik online, 97(9):644–650

Dopping-Hepenstal LL (1981) Head-up displays: the integrity of flight information. IEE Proc-F Commun Radar Signal Process 128(7):440–442

Yeh M, Wickens CD (2000) Attention and trust biases in the design of augmented reality displays. Technical report. Chicago, Aviation research lab of the University of Illinois

Zaeh MF, Wiesbeck M, Stork S, Schubö A (2009) Factors for a task-induced complexity measure for manual assembly operations. 3rd international conference on changeable, agile, reconfigurable and virtual production (CARV 2009), Munich, Germany, 2009

Picker C (2007) Prospektive Zeitbestimmung für nicht wertschöpfende Montagetätigkeiten, Aachen, Shaker

Hinckley M (1993) A global conformance quality model—a new strategic tool for minimizing defects caused by variation, error and complexity. Stanford University, Stanford

Beiter KA, Cheldelin B, Ishii K (2000) Assembly quality method: a tool in aid of product strategy, design and process improvements.In: ASME design engineering technical conference, Baltimore

Shibata H, Cheldelin B, Ishii K (2003) Assembly quality method: integrating design for assembly cost-effectiveness (DAC) to improve defect prediction. In: ASME design engineering technical conference, Chicago

Kim YH (1999) A system complexity approach for the integration of product development and production system design. Massachusetts Institute of Technology, Cambridge

Kief L (2002) Eine Methode zur Ermittlung statistisch abgesicherter Montagezeiten im Produktentwicklungsprozess. Verlag Praxiswissen, Dortmund

Westkämper E, Sautter K, Meyer R (1998) Eine Empirische Untersuchung zum Methodeneinsatz in Produzierenden Unternehmen. Fachtagung “Mehr Erfolg durch professionellen Methodeneinsatz”. Fraunhofer IRB, Darmstadt

Papenfuß R, Theis K-D (1988) Die WORK-FACTOR-Verfahren. Angewandte Arbeitswissenschaft 117:3–18

Boothroyd G, Alting L (1992) Design for assembly and disassembly. Ann CIRP 41(2):625–636

Miyakawa S, Ohashi T (1986) The Hitachi assembly evaluation method (AEM). In: International conference on product design for assembly, Newport, Rhode Island

Bokranz R, Landau K (2006) Produktivitätsmanagement von Arbeitssystemen. Schäffer-Poeschel, Stuttgart

Wickens CD (2002) Multiple resources and performance prediction. Theor Issues Ergon Sci 32:159–177

Stoessel C, Wiesbeck M, Stork S, Zaeh MF, Schuboe A (2008) Towards optimal worker assistance: investigating cognitive processes in manual assembly. In: Mitsuishi M, Ueda K, Kimura F (Eds.) The 41st CIRP conference on manufacturing systems. Springer, Tokyo, Japan

Stork S, Stobel C, Müller H, Wiesbeck M, Schubö A (2007) A neuroergonomic approach for the investigation of cognitive processes in interactive assembly environments.In: 16th IEEE international symposium on robot and human interactive communication 2007 (IEEE RO-MAN 2007)

Norman DA, Bobrow DG (1975) On data-limited and resource-limited processing. Cogn Psychol 74:4–64

Müller HJ, Krummenacher J (2002) Aufmerksamkeit. In: Müsseler J, Prinz W (eds) Allgemeine Psychologie. Elsevier, Heidelberg

Jayaram S, Connacher H, Lyons K (1997) Virtual assembly using virtual reality techniques. Comput Aided Des 29(88):575–584

Gupta R, Whitney D, Zeltzer D (1997) Prototyping and design for assembly analysis using multimodal virtual environments. Comput Aided Des 29(88):585–597

Carpenter ID, Dewer RG, Richie JM, Simmons JEL (1996) Enhancing a virtual environment for manual assembly. In: 12th international conference on CAD/CAM robotics and factories of the future

Homem de Mello LS, Sanderson AC (1991) Representations of mechanical assembly sequences. IEEE Trans Rob Autom 7(2):211–227

Sanderson AC, Zhang H, Homem de Mello LS (1989) Assembly sequence planning. Manuscript prepared for AI Magazine: special issue on assembly planning, Vol 33

Lee S (1992) Backward assembly planning with assembly cost analysis. In: Proceedings of 1992 IEEE international conference on robotics and automation. Nice

Homem de Mello LS, Sanderson AC (1991) A correct and complete algorithm for the generation of mechanical assembly sequences. IEEE Trans Rob Autom 7(2):228–240

Gu T, Xu Z, Yang Z (2008) Symbolic OBDD representations for mechanical assembly sequences. Comput Aided Des 40(4):411–421

Iyer N, Jayanti S, Lou K, Kalyanaraman Y, Ramani K (2005) Three-dimensional shape searching: state-of-the-art review and future trends. Comput Aided Des 37(5):509–530

Dmitriy B, Cheuk Yiu I, William CR, Joshua S (2005) Benchmarking CAD search techniques. In: Proceedings of the 2005 ACM Symp on solid and physical modeling. Cambridge, Massachusetts

Stork S, Stössel C, Schubö A (2008) The influence of instruction mode on reaching movements during manual assembly. USAB 2008—Usability—HCI for education and work, lecture notes in computer science LNCS, Austria, Graz

Stork S, Stössel C, Schubö A (2008) Optimizing Human–Machine Interaction in Manual Assembly. In: Proceedings of 17th IEEE international conference on robot and human interactive communication (RO-MAN)

Acknowledgments

The present research is conducted within the Cluster of Excellence CoTeSys—Cognition for Technical Systems in Munich, Germany. It aims for a considerable utilization and establishment of cognitive capabilities in technical systems.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zaeh, M.F., Wiesbeck, M., Stork, S. et al. A multi-dimensional measure for determining the complexity of manual assembly operations. Prod. Eng. Res. Devel. 3, 489 (2009). https://doi.org/10.1007/s11740-009-0171-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11740-009-0171-3