Abstract

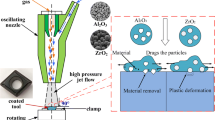

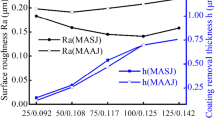

In today’s production engineering nearly every cutting tool is coated. Since using the technology of coating different process chains for reconditioning have been developed. The last innovation is micro blasted coatings, which is the main topic of this paper. Concerning this topic influences on tool life have been investigated. Investigations on the tool life especially of hobbing tools were made thereby and coherences between coating bond, roughness and other attributes were discovered. The investigations were made with an aluminum oxide and a zirconium oxide as blasting abrasives and a variation of the blasting parameters pressure and period. The final result is an optimization of tool wear behavior by micro blasting of the coating.

Similar content being viewed by others

References

Kleinjans M (2003) Einfluss der Randzonen-eigenschaften auf den Verschleiß von beschich-teten Hartmetallwälzfräsern. Doctoral thesis, RWTH Aachen University

Toenshoff H-K, Mohlfeld A (1998) Surface treatment of cutting tool substrates. Int J Mach Tools Manuf 3:469–476

Bouzakis K-D, Skordaris G, Michailidis N, Asimalopoulus A, Erkens G (2005) Effect on PVD-coated cemented carbide inserts cutting performance of micro blasting and lapping of their substrates. Surf Coat Technol 200:128–132

Sulzer G (2000) Verschleiss-Überwachung beim Trockenfräsen von Verzahnungen. VDI Berichte 1532:65–77

Bunshah R (2001) Handbook of hard coatings, edition. Noyes, Norwich

Guide line VDI 3324 (1999) Leistendrehtest—Prüfverfahren zur Beurteilung des Bruchverhaltens und der Einsatzsicherheit von Schneiden aus Hartmetall beim Drehen

Winkel O (2003) Steigerung der Leistungsfähigkeit von Hartmetallwälzfräsern durch eine optimierte Wer5kzeuggestaltung. Doctoral thesis, RWTH Aachen University

Acknowledgments

The authors gratefully acknowledge the support of deutsche forschungsgemeinschaft dfg.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Klocke, F., Gorgels, C., Bouzakis, E. et al. Tool life increase of coated carbide tools by micro blasting. Prod. Eng. Res. Devel. 3, 453 (2009). https://doi.org/10.1007/s11740-009-0173-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11740-009-0173-1