Abstract

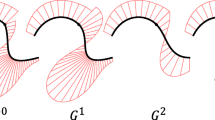

This article introduces a method for generating and analyzing CAD models of mould cavities to compute the tool accessibility. Using information about the surface curvature, a determination of working areas for different milling head geometries becomes possible. Relating groups of surfaces with milling heads and specific cutting data allows calculating the manufacturing time of roughing and finishing operations, including the tool change time. Determining the working areas, inaccessible for milling heads, enables to estimate the volume of material that needs to be eroded. A CAD-based application of the calculation tool `Visual Form Calculator’ (VFC), developed at IFW, is presented. Using the VFC, companies of the tool and form making industry are able to generate a virtual model of the contour element in order to analyze the accessibility of the working areas of the cavity and calculate manufacturing costs.

Similar content being viewed by others

References

Schuh G, Klotzbach C, Gaus F (2008) Service provision as a sub-model of modern business models. Prod Eng Res Dev (WGP) 2:79–84

Fonseca M, Henriques E, Ferreira A, Jorge J (2007) Assisting mould quotation through retrieval of similar data. In: Maropaulos PG, Cunha P (eds) Digital Enterprise Technology. Springer, US, pp 527–534

Denkena B, Lorenzen L-E, Schürmeyer J (2009) Rule based quotation costing of pressure die casting moulds. Prod Eng Res Dev (WGP) 3(1):87–94

Zäh MF, Hagemann F (2009) Form-flexible tools for injection modling: approach for the economic application of injection molding for small lot sizes. Prod Eng Res Dev (WGP) 3:281–285

Denkena B, Schuermeyer J (2001) Integrating geometry information in the bid generation of die casting moulds, chap. 61. In: Katalinic B (ed) DAAAM International Scientific Book 2009. DAAAM International, Vienna, pp 629–642 ISBN 978-3-901509-71-1, ISSN 1726-9687

Farineau T, Rabenasoslo B, Castelain JM, Meyer Y, Duverlie P (2001) Use of Parametric models in an economic evaluation step during the design phase. J Adv Manuf Technol 17:79–86

Chan SF, Law CK, Chan KK (2003) Computerising price quotation systems for injection mould manufacture. J Mater Process Technol 139:212–218

Bouaziz Z, Ben Younes J, Zghal A (2006) Cost estimation system of dies manufacturing based on the complex machining features. Int J Adv Manuf Technol 28:262–271

Knoblach J (1999) Beitrag zur rechnergestützten verursachungsgerechten Angebotskalkulation von Blechteilen mit Hilfe wissensbasierter Methoden, Dr.-thesis, Universität Erlangen

Grundmann M (1994) Entwicklung eines Kalkulationsinstrumentariums für Spritzgussbetriebe auf Basis von Ähnlichkeitsbetrachtungen, Dr.-thesis, RWTH Aachen

Brunkhorst U (1995) Integrierte Angebots- und Auftragsplanung im Werkzeug- und Formenbau, Dr.-thesis, Leibniz Universität Hannover

Wang H, Zhou XH, Ruan XY (2003) Research on Injection Mould Intelligent Cost Estimation System and Key Technologies. Int J Adv Manuf Technol 21(3):215–222

Milberg J, Müller S (2007) Integrating configuration and holistic evaluation of technology chains within process planning. Prod Eng Res Dev (WGP) 1:401–406

Fagade A, Kazmer DO (2000) Early cost estimation for injection molded parts. J Injection Mould Technol 4(3):97–106

Nagahanumaiah K, Ravi B, Mukherjee NP (2005) An integrated framework for die and mold cost estimation using features and tooling parameters. Int J Adv Manuf Technol 26:1138–1149

Ort A (2000) Entwicklungsbegleitende Kalkulation mit Teilebibliotheken, Dr.-thesis, TU Clausthal

Schuh G (2005) Produktkomplexität managen: Strategien – Methoden – Tools. Carl Hanser Verlag, München, Wien

Westkämper E, von Briel R (2001) Continuous improvement and participative factory planning by computer systems. CIRP Annals – Manuf Technol 50(1):347–352

Choi SH, Cheung HH (2008) A versatile virtual prototyping system for rapid product development. Comput Ind 59:477–488

Li H, Huang T, Guo HL, Baldwin A, Chan N, Wong J (2008) Integrating design and construction through virtual prototyping. Autom Constr 17:915–922

Söderberg R, Wickman C, Lindkvist L (2008) Improving decision making by simulating and visualizing geometrical variation in non-rigid assemblies. CIRP Annals – Manuf Technol 57:175–178

Fuh JYH, Zhang YF, Nee AYC, Fu MW (2004) Computer-aided injection mold design and manufacture. Marcel Dekker Inc, New York

Deutsches Institut für Normung e.V. (DIN): DIN 32992: (1989) Cost information, calculation principles, types and methods of calculation

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Denkena, B., Schürmeyer, J., Böß, V. et al. CAD-based cost calculation of mould cavities. Prod. Eng. Res. Devel. 5, 73–79 (2011). https://doi.org/10.1007/s11740-010-0277-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11740-010-0277-7