Abstract

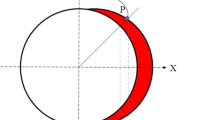

Mechanical machining of fiber reinforced plastics poses special challenges due to the heterogeneous and anisotropic material composition. Process strategies for the generation of drill holes, which aim at directing the resultant process forces toward the center of the workpiece, have been shown to obtain good machining results with less process induced damage. However, these strategies (e.g. wobble milling) might involve complex multiaxial tool movements and are thus very difficult to analyze and optimize. A voxel-based kinematic simulation program has been set up, which allows analyses of process forces for arbitrary milling operations based on the time-resolved determination of the cutting thickness and multivariate process force regression models. A basic analysis of the process of wobble milling is presented as well. It confirms that the resultant process forces are directed toward the center of the workpiece when the outer material layers are machined. The resultant force is directed in a favorable direction throughout the complete cut during the actual process step of wobble milling.

Similar content being viewed by others

Abbreviations

- dh :

-

Hole diameter

- dt :

-

Tool diameter

- ES:

-

Element size

- ft,r :

-

Radial feed per tooth

- h:

-

Cutting thickness

- kc, kp, kλ :

-

Specific cutting, passive and axial force (tool)

- kx, ky, kz :

-

Spatial force components (workpiece)

- POI:

-

Point of interest

- rβ :

-

Cutting edge radius

- vc :

-

Cutting velocity

- Δt:

-

Timestep

- Δz:

-

Disc thickness (tool discretization)

- λ:

-

Tool spiral angle

- ξ:

-

Effective force angle

- φ:

-

Tool inclination angle

- ψ:

-

Fiber orientation angle

References

König W, Graß P (1989) Quality definition and assessment in drilling of fibre reinforced thermosets. Ann CIRP 38:119–124

Persson E, Eriksson I, Zackrisson L (1997) Effects of hole machining defects on strength and fatigue life of composite laminates. Compos A 28:141–151

Khashaba UA, El-Sonbaty IA, Selmy AI, Megahed AA (2010) Machinability analysis in drilling woven GFR/epoxy composites: part I—effect of machining parameters. Compos A 41:391–400

Hocheng H, Dharan CKH (1990) Delamination during drilling in composite laminates. J Eng Ind 112:236–239

Jain S, Yang DCH (1991) Effects of feedrate and chisel edge on delamination in composites drilling. In: Processing and manufacturing of composite materials, Proceedings of the 112th ASME winter annual meeting, pp 37–51

Hocheng H, Tsao CC (2003) Comprehensive analysis of delamination in drilling of composite materials with various drill bits. J Mater Process Technol 140:335–339

Tsao CC, Hocheng H (2004) Taguchi analysis of delamination associated with various drill bits in drilling of composite material. Int J Mach Tools Manuf 44:1085–1090

Jansen R (2003) Bohren und Zirkularfräsen von Schichtverbunden aus Aluminium, CFK und Titanlegierungen. Dissertation Universität Bremen

Weinert K, Kempmann C (2005) Bohren oder Fräsen—das ist hier die Frage. Technica 54(5):16–19

Schulze V, Becke C (2009) Taumelfräsen zur schädigungsarmen Bohrbearbeitung von Kompositwerkstoffen. ZWF Zeitschrift für wirtschaftlichen Fabrikbetrieb 104(6):473–477

Schulze V, Becke C, Weidenmann K, Dietrich S (2011) Machining strategies for hole making in composites with minimal workpiece damage by directing the process forces inwards. J Mater Process Technol 211:329–338

Gonzalo O, Beristain J, Jauregi H, Sanz C (2010) A method for the identification of the specific force coefficients for mechanistic milling simulation. Int J Mach Tools Manuf 50:765–774

Kline WA, Devor RE, Shareef LA (1982) Prediction of surface accuracy in end milling. J Eng Ind 101:272–278

Adetoro OB, Wen PH (2010) Prediction of mechanistic cutting force coefficients using ALE formulation. Int J Adv Manuf Technol 46:79–90

Ungemach E, Surman T, Zabel A (2008) Dynamics and temperature simulation in multi-axis milling. Adv Mater Res 43:89–96

Kalla D, Sheikh-Ahmad J, Twomey J (2010) Prediction of cutting forces in helical end milling fiber reinforced polymers. Int J Mach Tools Manuf 50:882–891

Schulze V, Becke C, Pabst R (2011) Specific machining forces and resultant force vectors for machining of reinforced plastics. CIRP Ann Manuf Technol 60:69–72

Hou Z (2003) Beitrag zur voxelbasierten Simulation des fünfachsigen NC-Fräsens. Dissertation Technische Universität Berlin

Zabel A, Stautner M (2005) Einsatzfelder der mehrachsigen Frässimulation. wt Werkstattstechnik Online 95(1–2):56–61

Faraz A, Biermann D, Weinert K (2009) Cutting edge rounding: an innovative tool wear criterion in drilling CFRP composite laminates. Int J Mach Tools Manuf 49:1185–1196

Acknowledgments

The authors wish to thank the DFG-Deutsche Forschungsgemeinschaft (German Research Foundation) for funding and supporting the presented work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Schulze, V., Spomer, W. & Becke, C. A voxel-based kinematic simulation model for force analyses of complex milling operations such as wobble milling. Prod. Eng. Res. Devel. 6, 1–9 (2012). https://doi.org/10.1007/s11740-011-0348-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11740-011-0348-4