Abstract

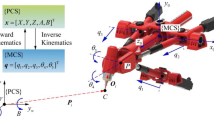

The redundancy of a 6R industrial robot is resolved for five-axis milling applications. This paper describes a post-processor focused algorithm that is adequate to numerically solve the redundancy with multiple constraints. Some critical constraints for cutting process, such as singularity, joint limits and collision are considered. The corresponding criterion functions are designed for the optimization procedure. Those constraints are synthesized as the multi-objective function to be minimized. A example of tool path testing the functionality of the optimization algorithm is presented. The optimization process is implemented into a 3D simulation system for the cutting robot. Some test pieces are cut to validate the feasibility of the algorithm.

Similar content being viewed by others

References

Xiao W, Strauß H, Loohß T, Hoffmeister HW, Hesselbach J (2011) Closed-form inverse kinematics of 6r milling robot with singularity avoidance. Prod Eng Res Dev 5(1):103–110

Abele E (2007) Spanende bearbeitung mit industrierobotern, forschungsprojekt advocut: Entwicklungen und industrietransfer. Technical report, Institut für Produktionsmanagement, Technische Universität Darmstadt

Nakamura Y (1991) Advanced robotics: redundancy and optimization. Addison-Wesley series in electrical and computer engineering: control engineering. Addison-Wesley, Boston

Seng J, O’Neil KA, Chen YC (1995) Escapability of singular configuration for redundant manipulators via self-motion. IEEE/RSJ Int Conf Intell Robots Syst 3:3078

Soeby K (2007) Inverse kinematics of five-axis machines near singular configurations. Int J Mach Tools Manuf 47(2):299–306

Jung YH, Lee DW, Kim JS, Mok HS (2002) Nc post-processor for 5-axis milling machine of table-rotating/tilting type. J Mater Process Technol 130(131):641–646

Affouard A, Duc E, Lartigue C, Langeron JM, Bourdet P (2004) Avoiding 5-axis singularities using tool path deformation. Int J Mach Tools Manuf 44(4):415–425

Munlin M, Makhanov SS, Bohez ELJ (2004) Optimization of rotations of a five-axis milling machine near stationary points. Comput Aided Des 36(12):1117–1128

Liegeois A (1977) Automatic supervisory control of the configuration and behavior of multibody mechanisms. IEEE Trans Syst Man Cybern 7(12):868–871

Klein CA, Chu-Jenq C, Ahmed S (1995) A new formulation of the extended jacobian method and its use in mapping algorithmic singularities for kinematically redundant manipulators. IEEE Trans Robot Autom 11(1):50–55

Lu Z (2006) Theory and application of robots with redundant degrees of freedom. China Machine Press, Beijing (in Chinese)

Baillieul J (1985) Kinematic programming alternatives for redundant manipulators. In: Proceedings of IEEE international conference on robotics and automation, vol 2, pp 722–728

Baillieul J (1986) Avoiding obstacles and resolving kinematic redundancy. In: Proceedings of IEEE international conference on robotics and automation, vol 3, pp 1698–1704

Yoshikawa T (1985) Manipulability and redundancy control of robotic mechanisms. In: Proceedings of IEEE international conference on robotics and automation, vol 2, pp 1004–1009

Paul RP (1981) Robot manipulators mathematics, programming, and control. The Massachusetts Institute of Technology, Cambridge

Bazaraa MS, Sherali HD, Shetty CM (2006) Nonlinear programming theory and algorithms, 3rd edn. Wiley, New York

Tchoń K, Muszyński R (1997) Singularities of nonredundant robot kinematics. Int J Robot Res 16:60–76

Nof SY (1985) Handbook of industrial robotics. Wiley, New York

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xiao, W., Huan, J. Redundancy and optimization of a 6R robot for five-axis milling applications: singularity, joint limits and collision. Prod. Eng. Res. Devel. 6, 287–296 (2012). https://doi.org/10.1007/s11740-012-0362-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11740-012-0362-1