Abstract

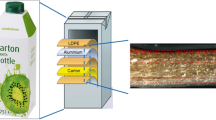

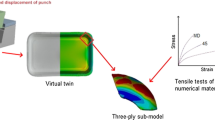

The material behavior of two different types of paperboard was characterized in tensile tests and in a new test device called paperboard bulge test. A particularly adapted hydroforming process was used to produce three-dimensional paperboard structures. Furthermore, an online measurement device to describe the mold-filling behavior is introduced. The experimental results were compared to the results obtained with an FEA investigation. The investigations showed the possibilities of the new forming process, as well as the advantages of FEA methods used to pre-define the process parameters.

Similar content being viewed by others

Notes

The kraft process (also known as sulfate process) is the predominant chemical technology to convert wood into separated cellulose fibers.

Beating is a mechanical treatment of fibers that usually leads to better strength properties by increasing the fibers’ hydrogen bonding ability.

The Schopper-Riegler freeness of a fibrous suspension is a measure for the dehydration capacity of the suspension, which correlates with the results of beating.

References

Scherer K (1932) Untersuchungen über die Ziehfähigkeit und den Ziehvorgang von Pappe. Sächsische Technische Hochschule zu, Dresden

Hauptmann M (2010) Die gezielte Prozessführung und Möglichkeiten zur Prozessüberwachung beim mehrdimensionalen Umformen von Karton durch Ziehen, in Institut für Verarbeitungsmaschinen und Mobile Arbeitsmaschinen. TU Dresden, Dresden

Mozetic L (2008) Design and development of laboratory equipment for forming of double-curved paperboard surfaces, in department of solid mechanics. KTH, Royal Institute of Technology, Stockholm

Isaksson P, Hägglund R, Gradin P (2004) Continuum damage mechanics applied to paper. Int J Solids Struct 41(16–17):4731–4755

Mäkelä P, Östlund S (2003) Orthotropic elastic-plastic material model fpr paper materials. Int J Solids Struct 40:5599–5620

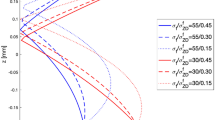

Huttel D, Post PP, Schabel S, Groche P, The stress strain behaviour of paperboard in tensile and bulge tests, in ICTP. 2011: Aachen

Panknin W (1959) Der hydraulische Tiefungsversuch und die Ermittlung von Fließkurven (The hydraulic bulge test and the determination of the flow stress curves). Universität Stuttgart, Stuttgart

Acknowledgments

The authors would like to thank the German Research Foundation (DFG) for its financial support of the project GR1818/37-1 and SCHA1246/2-1.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Groche, P., Huttel, D., Post, PP. et al. Experimental and numerical investigation of the hydroforming behavior of paperboard. Prod. Eng. Res. Devel. 6, 229–236 (2012). https://doi.org/10.1007/s11740-012-0365-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11740-012-0365-y