Abstract

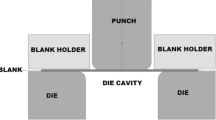

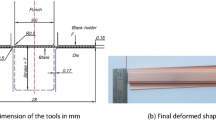

Springback is a really troublesome effect in sheet metal forming processes. In fact changes in geometry after springback are a big and costly problem in the automotive industry. In this paper the authors want to analyse the springback phenomenon experimentally in sheet metal hydroforming. Compared with conventional deep drawing, sheet hydroforming technology has many remarkable advantages, such as a higher drawing ratio, better surface quality, less springback, better dimensional freezing and capability to manufacture complicated shapes. The springback phenomenon has been extensively analysed in deep drawing processes but there are not many works in the literature about springback in sheet metal hydroforming. In order to study it, the authors have performed an accurate measuring phase on the chosen test cases through a coordinate measuring machine and the obtained measurements have been utilised for the determination of springback parameters, taking into account the method proposed by Makinouchi et al. The authors have focused their attention on the possibility of adopting a modified Makinouchi et al. approach in order to measure the springback of the large size considered test cases. Through the implemented methodology it has been possible to calculate the values of the springback parameters. The obtained results correspond to the observed experimental deformations. Analysing the springback parameter values of the different combinations investigated experimentally, the authors have also studied the pre-bulging influence on the springback amount.

Similar content being viewed by others

References

Meindersa T, Burchitza IA, Bonte MHA, Lingbeek RA (2008) Numerical product design: springback prediction, compensation and optimization. Int J Mach Tools & Manuf 48:499–514

Andersson A (2005) Numerical and experimental evaluation of springback in a front side member. J Mater Process Technol 169:352–356

Liu G, Lin Z, Xu W, Bao Y (2002) Variable blankholder force in U-shaped part forming for eliminating springback error. J Mater Process Technol 120:259–264

Zhang D, Cui Z, Ruan X, Li Y (2007) An analytical model for predicting springback and side wall curl of sheet after U-bending. Comput Mater Sci 38:707–715

Zhang ZT, Lee D (1995) Development of a new model for plane strain bending and springback analysis. JMEPEG 4:291–300

Li KP, Carden WP, Wagoner RH (2002) Simulation of springback. Int J Mech Sci 44:103–122

Hama T, Nagata T, Teodosiu C, Makinouchi A, Takuda H (2008) Finite-element simulation of springback in sheet metal forming using local interpolation for tool surfaces. Int J Mech Sci 50:175–192

Zhang D, Cui Z, Ruan X, Li Y (2006) Sheet springback prediction based on non-linear combined hardening rule and Barlat89’s yielding function. Comput Mater Sci 38:256–262

Carden WD, Geng LM, Matlock DK, Wagoner RH (2002) Measurement of springback. Int J Mech Sci 44:79–101

Makinouchi A, Nakamachi E, Onate E, Wagoner RH (1993) In: Proceedings of NUMISHEET’93. The Institute of Physical and Chemical Research, Isehara, Japan

Lim H, Lee MG, Sung JH, Wagoner RH (2008) Time-dependent springback. Int J Mater Form Suppl 1:157–160

Firat M, Kaftanoglu B, Eser O (2008) Sheet metal forming analyses with an emphasis on the springback deformation. J Mater Process Technol 196:135–148

Zampaloni M, Abedrabbo N, Pourboghrat F (2003) Experimental and numerical study of stamp hydroforming of sheet metals. Int J Mech Sci 45:1815–1848

Eggertsen PA, Mattiasson K (2010) On constitutive modeling for springback analysis. Int J Mech Sci 52:804–818

Sharma AnupK, Rout DineshK (2009) Finite element analysis of sheet hydromechanical forming of circular cup. J Mater Process Technol 209:1445–1453

Langa L, Li T, Zhou X, Danckert J, Nielsen KB (2007) The effect of the key parameters in the innovative hydroforming on the formed parts. J Mater Process Technol 187–188:304–308

Zhang SH, Wang ZR, Xu Y, Wang ZT, Zhou LX (2004) Recent developments in sheet hydroforming technology. J Mater Process Technol 151:237–241

Bruni C, Celeghini M, Geiger M, Gabrielli F (2007) A study of techniques in the evaluation of springback and residual stress in hydroforming. Int J Adv Manuf Technol 33:929–939

Lang L, Danckert J, Nielsen KB, Zhou X (2005) Investigation into the forming of a complex cup locally constrained by a round die based on an innovative hydromechanical deep drawing method. J Mater Process Technol 167:191–200

Del Prete A, Anglani A, Spagnolo A (2009) Progettazione e costruzione di un’attrezzatura flessibile per l’idroformatura di lamiere piane. LAMIERA ISSN 0391-5891 50–59

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Papadia, G., Del Prete, A. & Anglani, A. Experimental springback evaluation in hydromechanical deep drawing (HDD) of large products. Prod. Eng. Res. Devel. 6, 117–127 (2012). https://doi.org/10.1007/s11740-012-0367-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11740-012-0367-9