Abstract

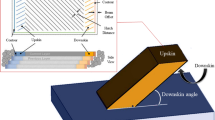

Deep drawing is one of the most important forming procedures for the economic production of sheet metal components. Especially for high-volume parts, deep drawing is a very efficient method of fabrication with high utilization of semi-finished parts. Certainly, conventional deep drawing processes are restricted by forming limits due to part failure during the drawing process. The process force is one of the most important factors for this restriction. The narrow process window, especially for deep drawing of light-weight materials, can be extended by reducing the friction forces at the die radius, using hydrostatic pressure lubrication. After the numerical analysis of the appearing loads of deep drawing processes, the optimal position for the insertion of pressurized lubricant was identified and the potential of the hydrostatic pressure lubrication was predicted. With experimental tests, the results of the simulations were approved. Both, the simulations and the experimental tests showed a significant reduction of the process forces.

Similar content being viewed by others

References

Stock G (1996) Alternative Verfahren zur Verbesserung des Tiefziehergebnisses auf einfach wirkenden Pressen. Universität Hannover, Dissertation

Weber T, Vöhringer K-D (2003) Innovative Produktionstechnologien für globale Märkte. 8. Umformtechnisches Kolloquium Darmstadt. Bamberg: Meisenbach

Neugebauer R, Altan T, Geiger M, Kleiner M, Sterzing A (2006) Sheet metal forming at elevated temperatures. Ann CIRP 55:793–816

Staeves J (1998) Beurteilung der Topografie von Blechen im Hinblick auf die Reibung bei der Umformung. Dissertation, Technische Universität Darmstadt, Berichte aus Produktion und Umformtechnik, Bd. 41, Shaker Verlag

Hortig D (2001) Werkzeugbeschichtungen mit Trockenschmierstoffeigenschaften für das Tiefziehen. Dissertation, Technische Universität Darmstadt, Berichte aus Produktion und Umformtechnik, Bd. 47, Shaker Verlag, Aachen

Mössle E (1983) Einfluss der Oberfläche beim Ziehen von Blechteilen aus Aluminium. Universität Stuttgart, Dissertation

Felder E, Payen G (2010) Mechanical analysis of the contact between the sheet and the blankholder in deep drawing. Proceedings of the 4th international conference on tribology in manufacturing processes (ICTMP), vol 2. Presses des Mines, pp 563–572

Behrens B-A, Huebner S, Eckold C-P, Groche P, Ertugrul M (2010) Development of a segmented hydro-elastic blank holder for deep drawing. Proceedings of the 4th international conference on tribology in manufacturing processes (ICTMP), vol 2. Presses des Mines, pp 563–572

Thiruvarudchelvan S, Tan MJ (2007) Fluid-pressure assisted deep drawing. J Mater Process Technol 192–193:8–12

Siebel E, Pomp A (1929) Über den Kraftverlauf beim Tiefziehen und bei der Tiefungsprüfung. Mitteilungen aus dem Kaiser-Wilhelm-Institut für Eisenforschung zu Düsseldorf, Bd. XI, Verlag Stahleisen, Düsseldorf, pp 139–147

Klöpsch C, Möller N (2009) Generierung lokaler, hydrostatischer Druckschmierungszustände beim Tiefziehen. EFB-Abschlussbericht Nr. 303

Bay N, Skytte Jensen S, Malberg MP, Grauslund S (1994) Forming limits in hydromechanical deep drawing. Ann CIRP 43:253–256

Murata M, Miyamoto H (2002) Characteristic and benefit of new deep drawing using high pressured water. Proceedings of the 7th ICTP, Yokohama, Japan

Klöpsch C (2009) Generierung lokaler, hydrostatischer Druckschmierungszustände beim Tiefziehen. Dissertation, Technische Universtät Darmstadt, Berichte aus Produktion und Umformtechnik, Bd. 81, Shaker Verlag, Aachen

Nitzsche G (2007) Reduzierung des Adhäsionsverschleißes beim Umformen von Aluminiumblechen. Dissertation, Technische Universität Darmstadt, Berichte aus Produktion und Umformtechnik, Bd. 72, Shaker Verlag, Aachen

Klein B (2010) FEM: Grundlagen und Anwendungen der Finite-Elemente-Methode im Maschinen- und Fahrzeugbau, 8th edn. Vieweg + Teubner Verlag, Springer Fachmedien, Wiesbaden

Kuwer C (2007) Verschleißreduktion beim Tiefziehen von X5CrNi 18-10. Dissertation, RWTH Aachen, Berichte aus der Produktionstechnik, Bd. 22, Shaker Verlag, Aachen

Acknowledgments

The investigations presented in this paper were carried out within the research project “Tribological optimization of deep drawing processes using servo presses” sponsored by Arbeitsgemeinschaft industrieller Forschungsvereinigungen “Otto von Guericke” e.V. (AiF), and Europäische Forschungsgesellschaft für Blechverarbeitung e.V. (EFB). At the same time, the authors would like to thank the following companies for their continuous and profound support during the project: Daimler AG, Filzek TRIBOtech, Fissler GmbH, Raziol Zibulla & Sohn GmbH, Hubert Stüken GmbH & Co. KG, and Zeller + Gmelin GmbH & Co. KG.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Groche, P., Kloepsch, C. & Moeller, N. Numerical analysis of the potential of deep drawing processes with hydrostatic pressure lubrication. Prod. Eng. Res. Devel. 6, 157–167 (2012). https://doi.org/10.1007/s11740-012-0374-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11740-012-0374-x