Abstract

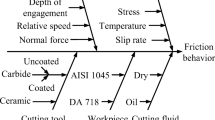

This paper investigates a new test to analyse the friction behaviour of the tool-chip interface under conditions that usually appear in metal cutting. The developed test is basically an orthogonal cutting process, that was modified to a high speed forming and friction process by using an extreme negative rake angle and a very high feed. The negative rake angle suppresses chip formation and results in plastic metal flow on the tool rake face. Through the modified kinematics and in combination with a feed velocity that is five to ten times higher than in conventional metal cutting, the shear and normal stresses are only acting in a simple inclined plane, allowing to calculate the mean friction coefficient analytically. In addition, the test setup allows to obtain the coefficient of friction for different temperatures, forces and sliding velocities. Experiments showed, that the coefficient of friction is strongly dependent on the sliding velocity for the example workpiece/tool material combination of C45E+N (AISI 1045) and uncoated cemented carbide.

Similar content being viewed by others

References

Shi B, Attia H (2010) Current status and future direction in the numerical modeling and simulation of machining processes: a critical literature review. Mach Sci Technol 14:149–188

Zorev NN (1963) Inter-relationship between shear processes occurring along tool face and shear plane in metal cutting. Int Res Prod Eng (ASME) 42–49

Usui E, Takeyama H (1960) A photo-elastic analysis of machining stresses on rake face. Trans ASME J Engng Ind 80:303–307

Childs THC, Mahdi MI, Barrow G (1989) On the stress distribution between the chip and tool during metal turning. CIRP Ann Manuf Technol 38:55–58

Merchant ME (1945) Mechanics of the metal cutting process. I. Orthogonal cutting and a type 2 chip. J Appl Phys 16:267–275

Barrow G et al (1982) Determination of rake face stress distribution in orthogonal machining. Int J Mach Tool Des Res 22:75–82

Neugebauer R et al (2011) Velocity effects in metal forming and machining processes. CIRP Ann Manuf Technol 60:627–650

Astakhov VP (2006) Tribology of metal cutting. Elsevier, Amsterdam

Olsson MO et al (1989) Simulation of cutting tool wear by a modified pin-on-disc test. Int J Mach Tool Manuf 29:377–390

Grzesik W, Zalisz Z, Nieslony P (2002) Friction and wear testing of multilayer coatings on carbide substrates for dry machining applications. Surf Coat Technol 155:37–45

Zemzemi F et al (2008) New tribometer designed for the characterisation of the friction properties at the tool/chip/workpiece interfaces in machining. Tribotest 14:11–25

Zemzemi F et al (2009) Identification of a friction model at tool/chip/workpiece interfaces in dry machining of AISI4142 treated steels. J Mater Process Technol 209:3978–3990

Hedenqvist P, Olsson M (1991) Sliding wear testing of coated cutting tool materials. Tribol Int 24:143–150

Bonnet C et al (2008) Identification of a friction model—application to the context of dry cutting of an AISI 316L austenitic stainless steel with a TiN coated carbide tool. Int J Mach Tool Manuf 48:1211–1223

Brocail J, Watremez M, Dubar L (2010) Identification of a friction model for modelling of orthogonal cutting. Int J Mach Tool Manuf 50:807–814

Schulze V et al (2011) Modelling of cutting induced surface phase transformations considering friction effects. Procedia Eng 19:331–336

Behrens B et al (2011) Advanced friction modeling for bulk metal forming processes. Prod Eng Res Dev 5:621–627

Acknowledgments

The authors would like to thank the German Research Foundation (DFG) for the funding of the depicted research within the priority programme 1480.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Puls, H., Klocke, F. & Lung, D. A new experimental methodology to analyse the friction behaviour at the tool-chip interface in metal cutting. Prod. Eng. Res. Devel. 6, 349–354 (2012). https://doi.org/10.1007/s11740-012-0386-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11740-012-0386-6